Existing line D beam overall longitudinally-moving construction method

A construction method and technology for this line, applied in the field of overall longitudinal movement of the D beam of this line, can solve the problems of long construction time, poor safety, and cumbersome construction procedures, so as to save construction time, release railway transportation capacity, and reduce key points of blockade. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

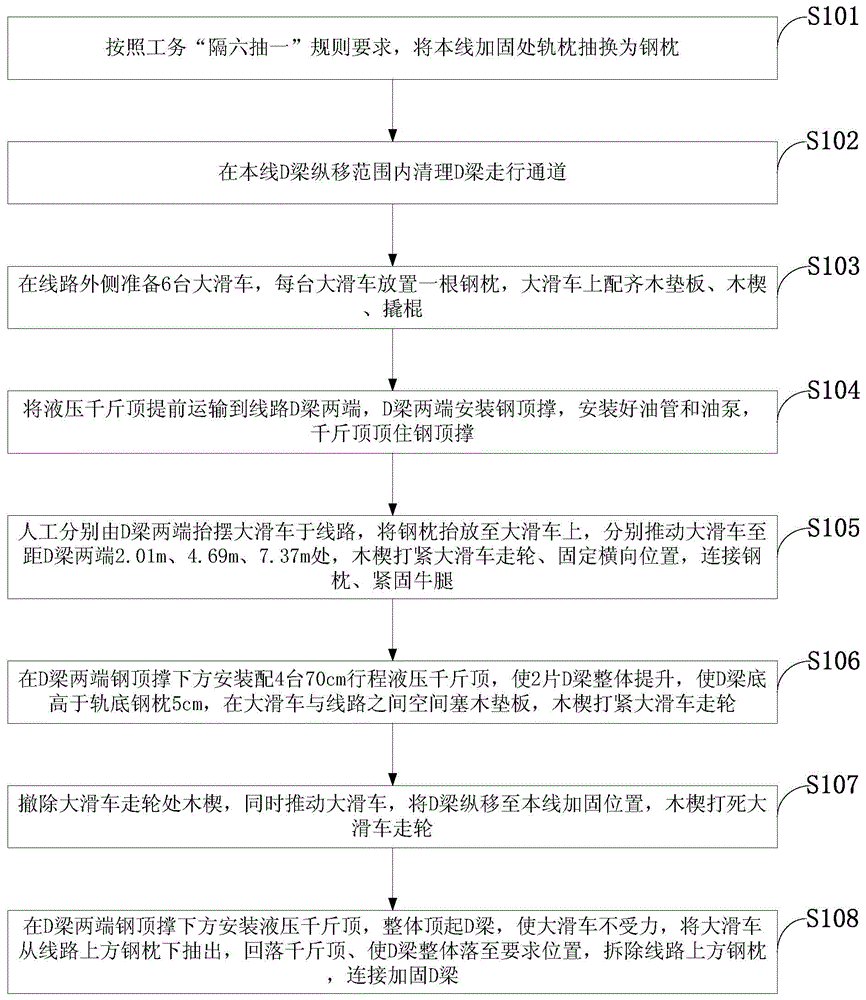

[0021] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] The application principle of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] During the jacking construction of the 2-16m frame structure on Heping East Street, Xinzhou City, two holes were prefabricated on the west side of the existing railway, crossing the Beitongpu Up and Down Line, Xinhe Line, and Pull Out Line, a total of 4 strands of road. 24m D beam reinforcement line, calculated according to the site D beam height layout, the D beam needs to be lifted 45cm above the steel sleeper at the bottom of the rail, put six large blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com