Warping adjustment method adopted in cardboard coating

An adjustment method and technology for fabricating white cardboard, applied in the field of adjusting the warpage of coated white cardboard, can solve problems such as paper and warpage that cannot be fundamentally solved, and achieve good economic benefits, good mechanical properties, and good film-forming properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]Use the following steps for warpage adjustment and production of coated white cardboard:

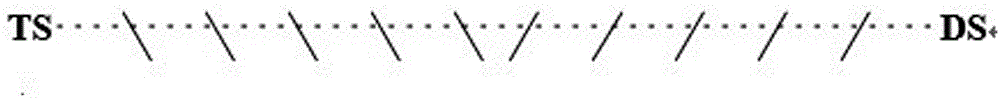

[0046] 1. Cut 10 A4 samples at average intervals on the paper machine banner paper, ensuring that the long side of the A4 samples is parallel to the direction of the paper machine, and then cut out a small cigarette label for each A4 sample, and press the 10 small cigarette labels Mark the sequence number from the operating side (TS) to the driving side (DS), put the reverse side up into the oven, put the 10 small cigarette labels after drying with the front side up, the paper machine direction of the cigarette labels is parallel to the visual direction, press the operation The side (TS) to the transmission side (DS) are arranged in sequence, and the fiber arrangement direction is drawn according to the principle that the fiber arrangement direction is perpendicular to the warping direction;

[0047] 2. It is found that the fiber arrangement directions drawn in step 1 are all in th...

Embodiment 2

[0051] Use the following steps for warpage adjustment and production of coated white cardboard:

[0052] 1. Cut 10 A4 samples at average intervals on the paper machine banner paper, ensuring that the long side of the A4 samples is parallel to the direction of the paper machine, and then cut out a small cigarette label for each A4 sample, and press the 10 small cigarette labels Mark the sequence number from the operating side (TS) to the driving side (DS), put the reverse side up into the oven, put the 10 small cigarette labels after drying with the front side up, the paper machine direction of the cigarette labels is parallel to the visual direction, press the operation The side (TS) to the transmission side (DS) are arranged in sequence, according to the principle that the fiber arrangement direction is perpendicular to the warping direction, such as image 3 Shown, draw the fiber arrangement direction, image 3 The oblique line of indicates the direction of fiber arrangemen...

Embodiment 3

[0059] Use the following steps for warpage adjustment and production of coated white cardboard:

[0060] 1. Cut 15 A4 samples at average intervals on the banner paper of the paper machine, make sure that the long side of the A4 samples is parallel to the direction of the paper machine, and then cut out 1 small cigarette label for each A4 sample, and press the Mark the sequence number from the operating side (TS) to the driving side (DS), put the reverse side up into the oven, put the 15 small cigarette labels after drying with the front side up, the paper machine direction of the cigarette labels is parallel to the visual direction, press the operation The side (TS) to the transmission side (DS) are arranged in sequence, according to the principle that the fiber arrangement direction is perpendicular to the warping direction, such as image 3 Shown, draw the fiber arrangement direction, image 3 The oblique line of indicates the direction of fiber arrangement, and the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com