Multi-component corrosion and scale inhibitor

A technology of corrosion and scale inhibitor and dispersant, which is applied in the fields of descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problem of water replenishment and system water quality not being very stable, increasing transportation costs, Unable to adjust and other problems, to achieve excellent corrosion and scale inhibition performance, reduce the amount of chemicals, reduce the effect of transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

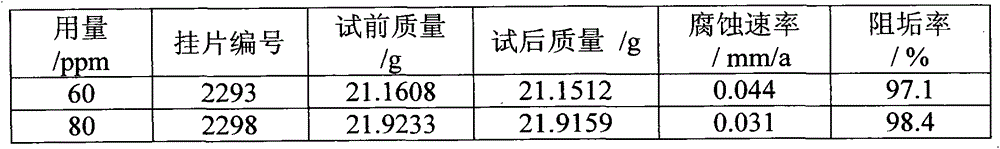

Embodiment 1

[0027] A corrosion and scale inhibitor suitable for medium and low hardness water, including A component and B component, wherein the main components of A component are: HEDP (60% aqueous solution) 20%, DTMPPA 5%, HPAA 15%, DDD45%, AA / AMPS15%. The main components of component B are: zinc chloride 75%, sodium hexametaphosphate 15%, sodium molybdate 10%. Compound A component and B component at a weight ratio of 2:1, and the dilution factor is 6 times. The specific preparation process is as follows: Take 11.3g of component A, 5.7g of component B, and 83g of water to prepare 100g of slow-release scale inhibitor solution. Apply the above solution to water with general hardness (total hardness is 180mg / L, total alkalinity is 112mg / L), and the dosing concentration is 60ppm and 80ppm.

[0028] In the test, the corrosion inhibition performance was tested in accordance with the standard of GB / T18175-2000 rotary coupon method, the test temperature was set at 45°C, the speed was set at ...

Embodiment 2

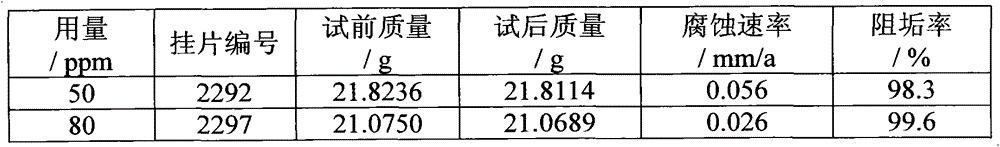

[0032] A high-efficiency corrosion and scale inhibitor suitable for medium and low hardness water, including component A and component B, wherein the main components of component A and component B are the same as those in Example 1. Compound A component and B component at a weight ratio of 2:3, and the dilution factor is 4 times. The specific preparation process is as follows: Take 10g of component A, 15g of component B, and 75g of water to prepare 100g of corrosion and scale inhibitor solution. The above solution was applied to water with relatively low hardness (90 mg / L total hardness and 72 mg / L total alkalinity), and the dosing concentration was 50 ppm and 80 ppm. The corrosion inhibition test method and scale inhibition test method are the same as in Example 1, and the specific results are shown in Table 2 below.

[0033] Table two: the experimental result of embodiment 2

[0034]

Embodiment 3

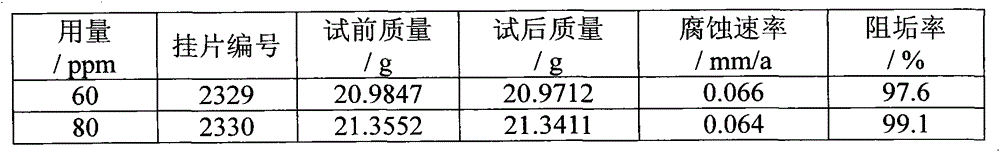

[0036]A high-efficiency corrosion and scale inhibitor suitable for medium and low hardness water, including A component and B component, wherein the main components of A component are: HEDP (60% aqueous solution) 21%, HPAA 16%, DDD 39% , T-22518%, deionized water 6%. The main components of component B are: zinc chloride 60%, sodium pyrophosphate 25%, sodium molybdate 15%. Compound A component and B component at a weight ratio of 1:1, and the dilution factor is 4 times. The specific preparation process is as follows: take 12.5g of component A, 12.5g of component B, and 75g of water to prepare 100g of corrosion and scale inhibitor solution. The above solution was applied to medium hardness water (total hardness is 343mg / L, total alkalinity is 223mg / L), and the dosing concentration is 60ppm and 80ppm. The corrosion inhibition test method and scale inhibition test method are the same as in Example 1, and the specific results are shown in Table 3 below.

[0037] Table three: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com