An inverted hydraulic movable lift and its use method

A lift and hydraulic technology, applied in the field of lifts, can solve the problems of inflexible use of mechanical jacks, inability to meet the needs of use, and high energy consumption of transmitted forces, so as to achieve convenient on-site assembly, simple structure, and no space occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

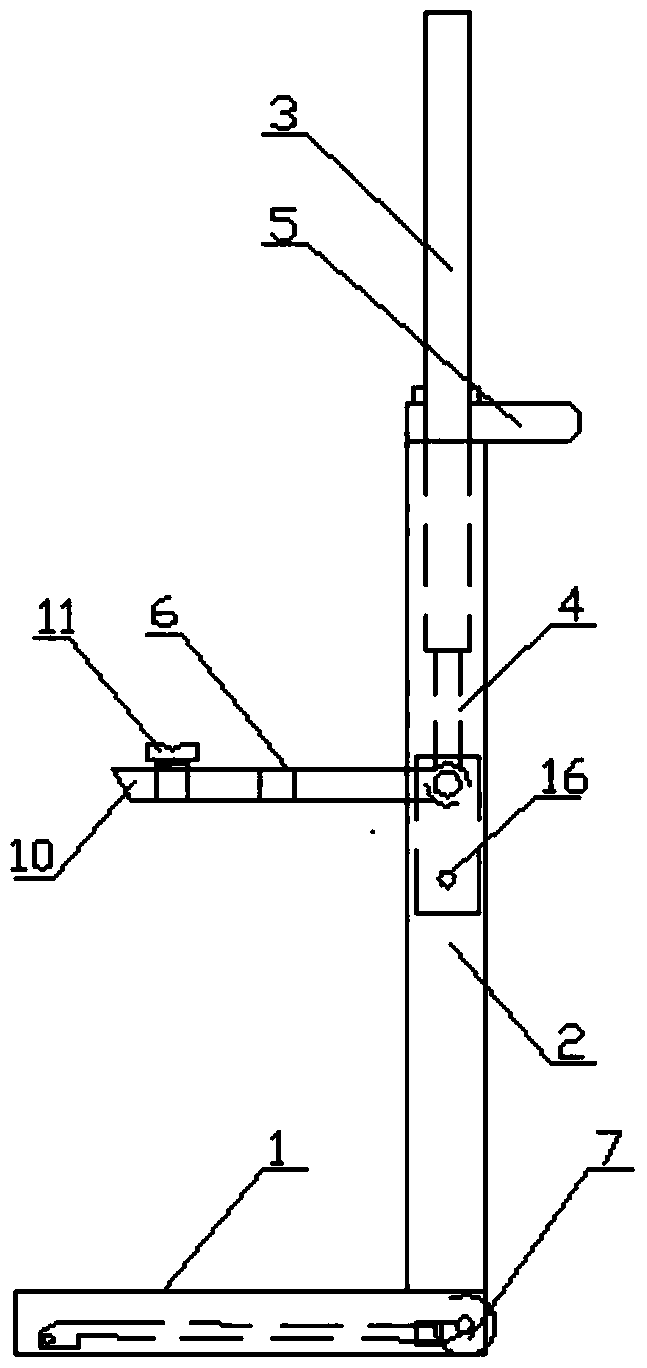

Embodiment 1

[0026] An inverted hydraulic movable lift, characterized in that it includes a mast, a load-bearing mechanism, a support leg and an oil pump, the bottom of the mast is vertically fixed to one end of the support leg, forming an L shape with the support leg, and the upper part of the mast is fixed There is an oil pump whose central axis coincides with the central axis of the mast. The oil pump includes a valve core and a sliding sleeve. Both sides of the sliding sleeve are fixed with connection ends, which are fixedly connected to the top of the mast through the connection end. The valve core is located at the lower part of the sliding sleeve. And it is between the masts, forming an inverted oil pump, the end of the valve core is fixedly connected with the load-bearing mechanism, the sliding sleeve is also provided with a hydraulic oil hole, and the oil pump has at least one section.

[0027] The oil pump can also be movably fixed on the door frame, the top of the door frame is p...

Embodiment 2

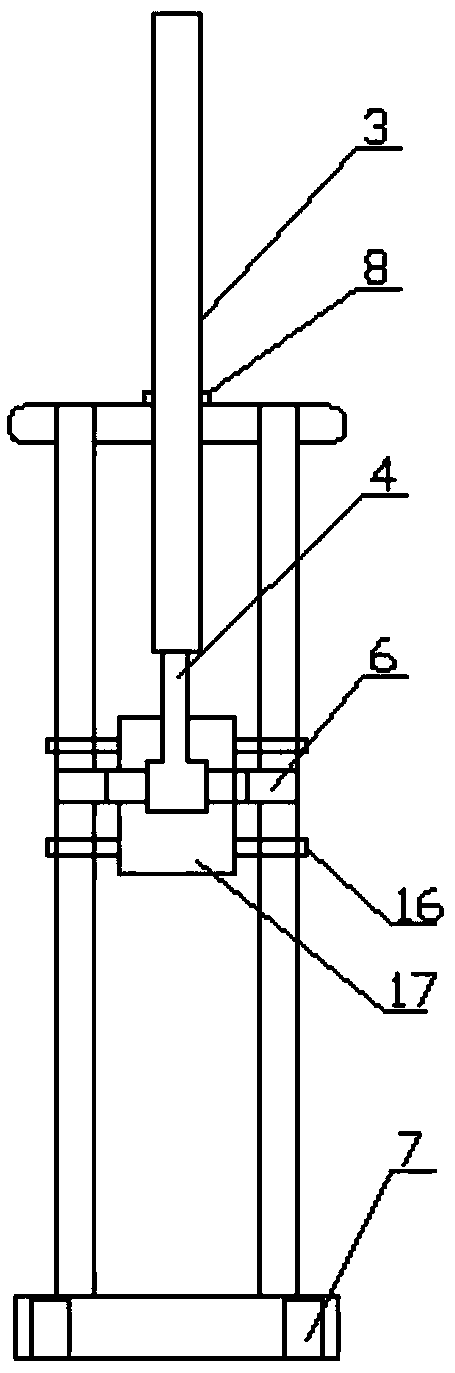

[0029] An inverted hydraulic movable lift, characterized in that it includes a mast, a load-bearing mechanism, a support leg and an oil pump, the bottom of the mast is vertically fixed to one end of the support leg, forming an L shape with the support leg, and the upper part of the mast is fixed There is an oil pump whose central axis coincides with the central axis of the mast. The oil pump includes a valve core and a sliding sleeve. Both sides of the sliding sleeve are fixed with connection ends, which are fixedly connected to the top of the mast through the connection end. The valve core is located at the lower part of the sliding sleeve. And it is between the masts, forming an inverted oil pump, the end of the valve core is fixedly connected with the load-bearing mechanism, the sliding sleeve is also provided with a hydraulic oil hole, and the oil pump has at least one section.

[0030] The oil pump can also be movably fixed on the door frame, the top of the door frame is p...

Embodiment 3

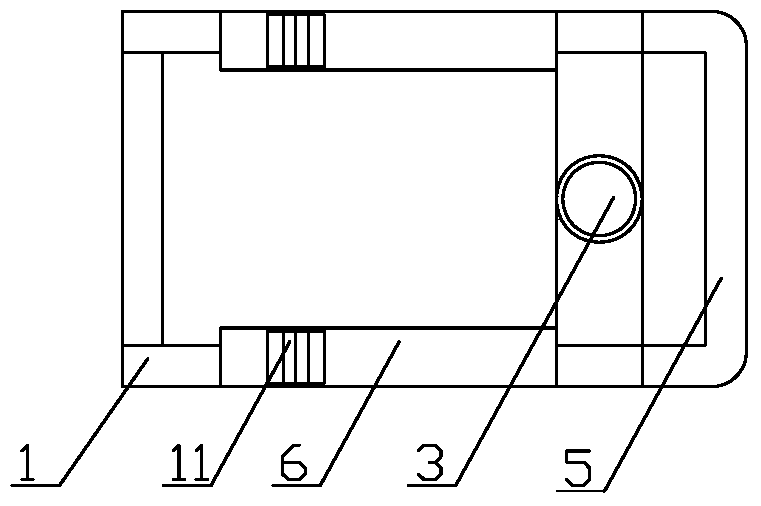

[0032] An inverted hydraulic movable lift, characterized in that it includes a mast, a load-bearing mechanism, a support leg and an oil pump, the bottom of the mast is vertically fixed to one end of the support leg, forming an L shape with the support leg, and the upper part of the mast is fixed There is an oil pump whose central axis coincides with the central axis of the mast. The oil pump includes a valve core and a sliding sleeve. Both sides of the sliding sleeve are fixed with connection ends, which are fixedly connected to the top of the mast through the connection end. The valve core is located at the lower part of the sliding sleeve. And it is between the masts, forming an inverted oil pump, the end of the valve core is fixedly connected with the load-bearing mechanism, the sliding sleeve is also provided with a hydraulic oil hole, and the sliding sleeve is provided with a single hydraulic oil hole, which is a single-pipe oil pump. The hydraulic oil hole can be located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com