Cloth pressing machine with ironing function

A cloth press and functional technology, which is applied in the field of cloth presses with ironing functions, can solve the problems of increasing labor intensity of workers, affecting the size of cutting, and easy to produce air bulges, etc., so as to avoid inaccurate cutting sizes and improve production Efficiency, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

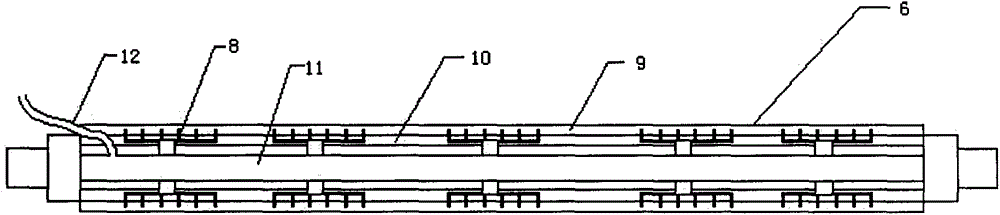

[0014] Such as Figure 1-2 As shown, a cloth pressing machine with an ironing function includes a frame 1, a cloth guide roller 2, a cloth spreading table 3, a pair of shaft roller seat brackets 4, a pair of pressing arms 5, and a cloth pressing bar 6; The cloth guide roller 2 and the cloth spreading table 3 are arranged on the frame 1, and a pair of shaft roller seat brackets 4 are installed on the left and right sides of the front end of the frame 1; One end, the other end of a pair of pressing arms 5 are respectively installed on a pair of shaft roller seat brackets 4 through the pressing arm bushing 7; The bottom plate 9 and the heating element 10, the annular bottom plate 9 is provided with the steam injection hole correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com