Method for manufacturing underground gas storage device for storing special gas

A special gas and manufacturing method technology, applied in storage devices, transportation and packaging, metal material coating process, etc., can solve problems such as limiting the wide application of underground gas storage wells, and achieve clean passivation effects, applicability and stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

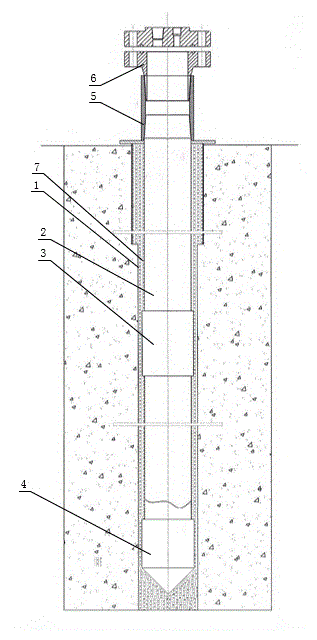

Image

Examples

Embodiment 1

[0092] A method for manufacturing an underground gas storage well device for storing special gas, comprising the following steps:

[0093] S1. Material selection: ensure that the material composition of the low-alloy structural steel components of the underground gas storage well device meets the following requirements:

[0094] The content of the following elements is calculated by weight percentage: C: 0.28%, Si: 0.17%, Mn: 0.40%, Cr: 0.80%, Ni: 0.25%, Mo: 0.15%, Cu: 0.25%, P: 0.020 %, S: 0.010%;

[0095] By selecting materials according to the above requirements, the present invention can be applied to the high-pressure special gas environment, ensuring the stability and reliability of the device structure when the underground gas storage well device is used to store the special gas.

[0096] S2. Degrease and passivate the low-alloy structural steel components of the underground gas storage well device: the low-alloy structural steel components are rinsed with water, degreas...

Embodiment 2

[0130] A method for manufacturing an underground gas storage well device for storing special gas, comprising the following steps:

[0131] S1. Material selection: ensure that the material composition of the low-alloy structural steel components of the underground gas storage well device meets the following requirements:

[0132] The content of the following elements is calculated by weight percentage: C: 0.33%, Si: 0.35%, Mn: 0.90%, Cr: 1.10%, Ni: 0.20%, Mo: 0.25%, Cu: 0.20%, P: 0.010% , S: 0.005%;

[0133] By selecting materials according to the above requirements, the present invention can be applied to the high-pressure special gas environment, ensuring the stability and reliability of the device structure when the underground gas storage well device is used to store the special gas.

[0134] S2. Degrease and passivate the low-alloy structural steel components of the underground gas storage well device: the low-alloy structural steel components are rinsed with water, degre...

Embodiment 3

[0168] A method for manufacturing an underground gas storage well device for storing special gas, comprising the following steps:

[0169] S1. Material selection: ensure that the material composition of the low-alloy structural steel components of the underground gas storage well device meets the following requirements:

[0170] The content of the following elements is calculated by weight percentage: C: 0.30%, Si: 0.25%, Mn: 0.70%, Cr: 0.90%, Ni: 0.18%, Mo: 0.20%, Cu: 0.21%, P: 0.015% , S: 0.008%;

[0171] By selecting materials according to the above requirements, the present invention can be applied to the high-pressure special gas environment, ensuring the stability and reliability of the device structure when the underground gas storage well device is used to store the special gas.

[0172] S2. Degrease and passivate the low-alloy structural steel components of the underground gas storage well device: the low-alloy structural steel components are rinsed with water, degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com