Vibration power generator

A vibration generator and magnetic vibration technology, applied in electrical components, electromechanical devices, etc., can solve problems such as the inability to use vibration energy or inertial energy, and the limitation of placement methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

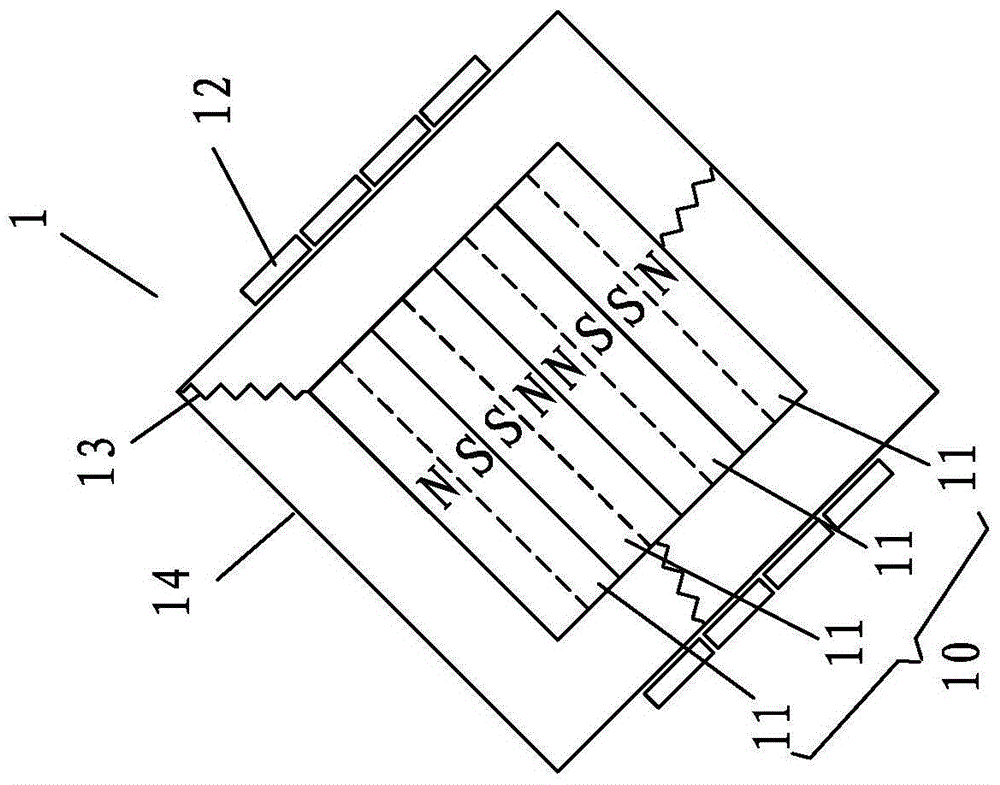

[0042] Such as Figures 1 to 8As shown, in this embodiment, a plurality of magnetic strips 11 are used to form an integrated magnon 10 , and each magnetic strip 11 is in the shape of a parallelepiped, so that a regular cube is formed to facilitate three-point positioning and suspension. A plurality of magnetic strips 11 are arranged side by side with opposite poles, with N poles facing N poles, S poles facing S poles, and the same poles facing each other can increase the change of the magnetic flux of the coil to the greatest extent. Each magnetic strip 11 is wound with a set of independent coils 12 respectively, the magnetic pole arrangement direction of the magnon 11 is perpendicular to the winding direction of the coil 12, and the winding width of each independent coil 12 is not larger than that of a single magnetic strip 11 in the vertical coil 12. The width in the winding direction.

Embodiment 2

[0044] Such as figure 1 As shown, in this embodiment, the magnon 10 is suspended in a housing 14 matching its shape by at least three springs 13 in a three-point positioning manner, and the housing 14 is made of non-magnetic material. When the magnon 10 is under the action of an external force in any direction, the magnon 10 will vibrate in any direction accordingly, and the vibration will cause the magnetic flux of the coil 12 to change, thereby generating a current, and electrically connecting the corresponding output ends of the coil 12 to external components , to provide power to external components.

Embodiment 3

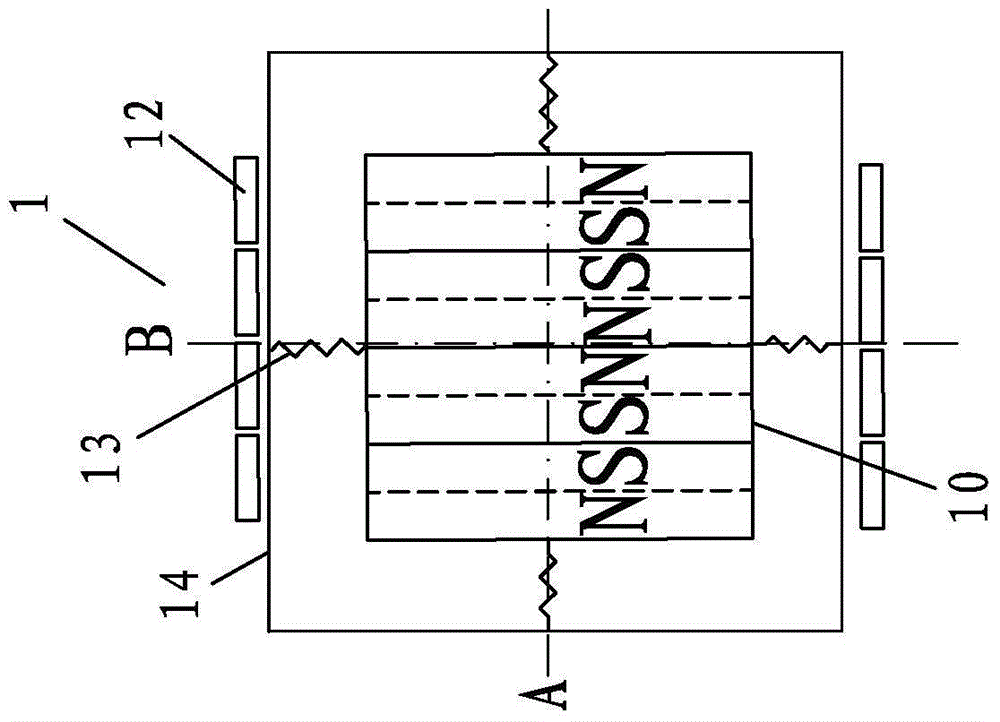

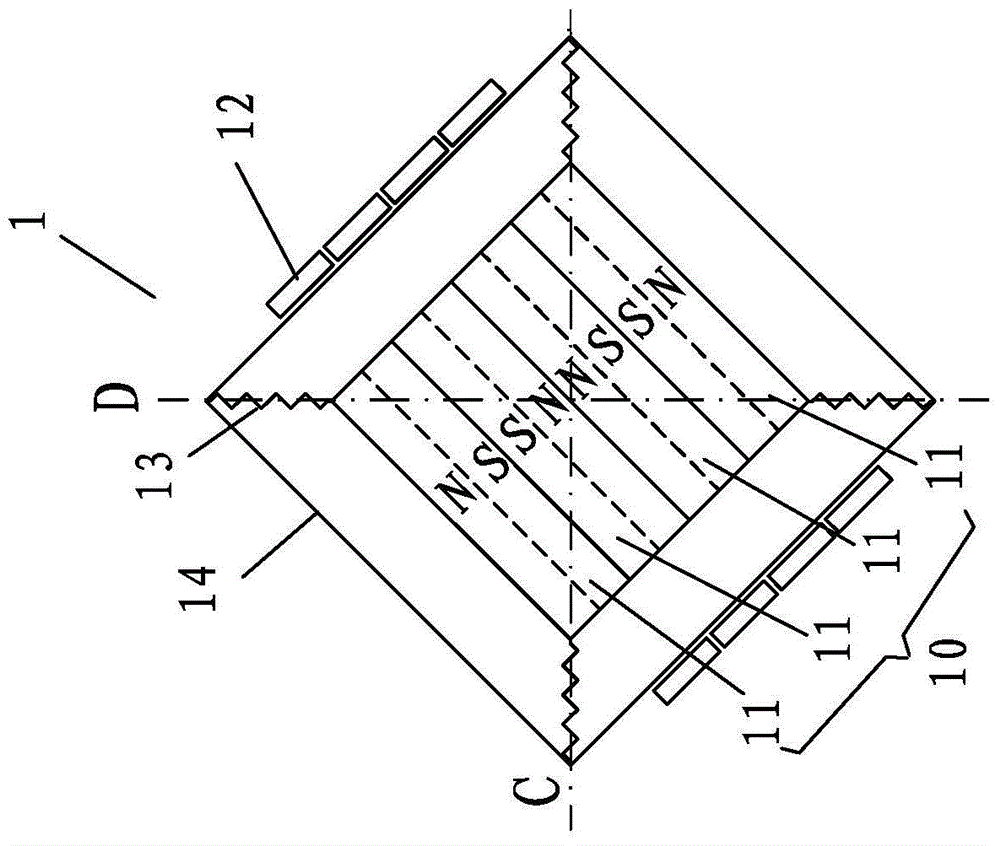

[0046] Such as figure 2 As shown, in this embodiment, the magnon 10 is suspended by four springs 13 along two intersection lines A and B or two diagonal lines C and D perpendicular to each other on at least one plane. Inside the coil 12. Connecting and suspending positioning on the diagonal through the spring 13 will have a better suspension positioning effect.

[0047] When each magnetic strip 11 is a regular shape, such as a parallelepiped, and the magnon 10 also forms a parallelepiped, then the two perpendicular intersection lines A and B or the two diagonal lines C and D are the symmetry lines of the magnon 10 respectively. , so that it is convenient to suspend the magnon 10 inside the casing 14 , and it is also convenient to wind the coil 12 outside the casing 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com