Novel damping ring structure for synchronous six-stage solid stator

A technology of solid rotor and damping ring, which is applied in the field of damping ring structure, can solve the problems of difficult pole shoe ends and easy throwing out, and achieve the effect of avoiding discharge problems and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

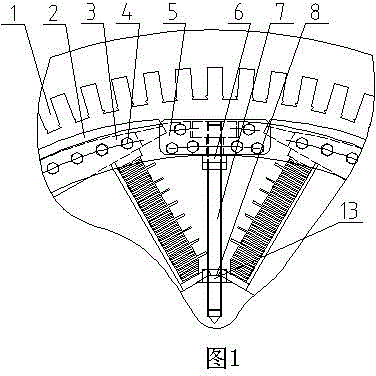

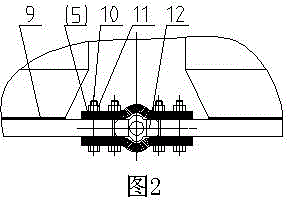

[0012] Attached below figure 1 And attached figure 2 This patent is further explained.

[0013] Such as figure 1 As shown, item (1) is the stator core of the motor, item (2) is the rotor pole piece, item (3) damping ring is connected with item (2) rotor pole piece through the item (4) bolt, and the end of the pole piece is connected with the damping Between rings such as figure 2 Pad item (9) silver spacer shown. The end of the damping ring is made as figure 1 The shape shown, between the damping rings of two adjacent magnetic poles, such as figure 2 As shown, use item (5) connecting piece to connect, and connecting piece and damping ring are connected together by item (10) bolt and item (11) nut. Between two adjacent damping rings such as figure 1 and figure 2 The item (12) shown in the figure is pressed on the cut corners of the two damping rings, and at the same time, the fixed block is as figure 1 The bolts shown in item (7) are connected together by threads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com