MCU (micro control unit) bus socket with shielding function

A technology of bus sockets and sockets, which is applied in the direction of protective grounding/shielding devices, bases/shells, coupling devices, etc. of connecting parts, and can solve the unsuitable volume requirements of power sockets, large electrical clearances and creepage distances, and large volumes of insulating mounting plates and other issues to achieve the effect of ensuring product consistency, improving production efficiency, and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

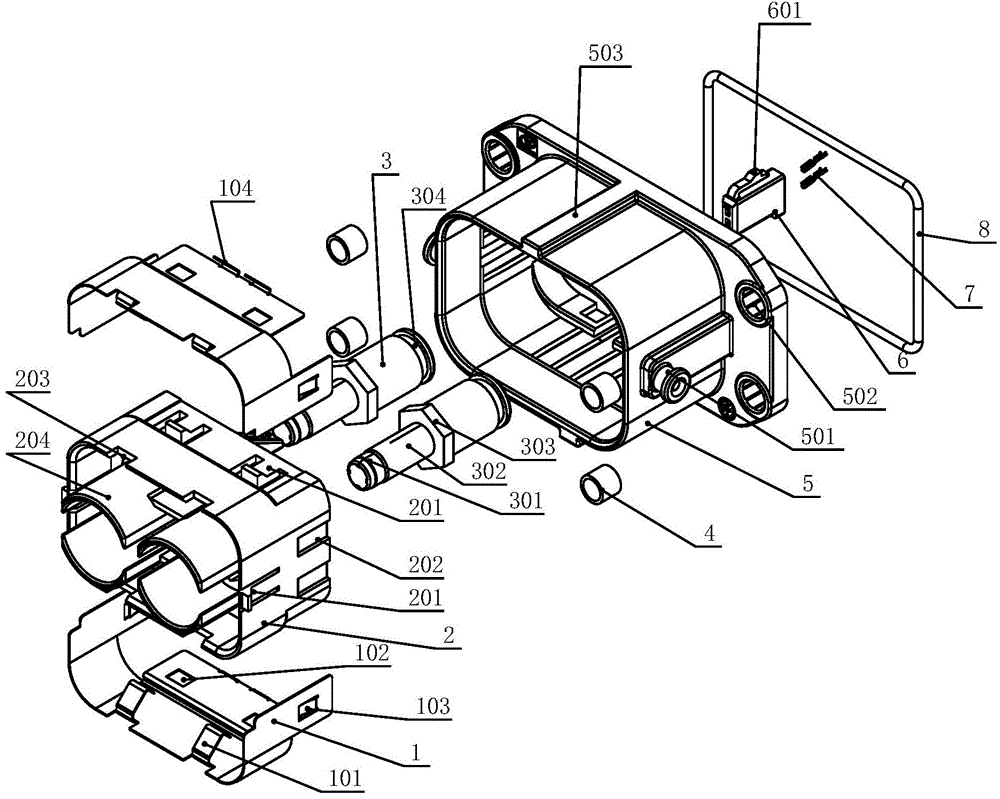

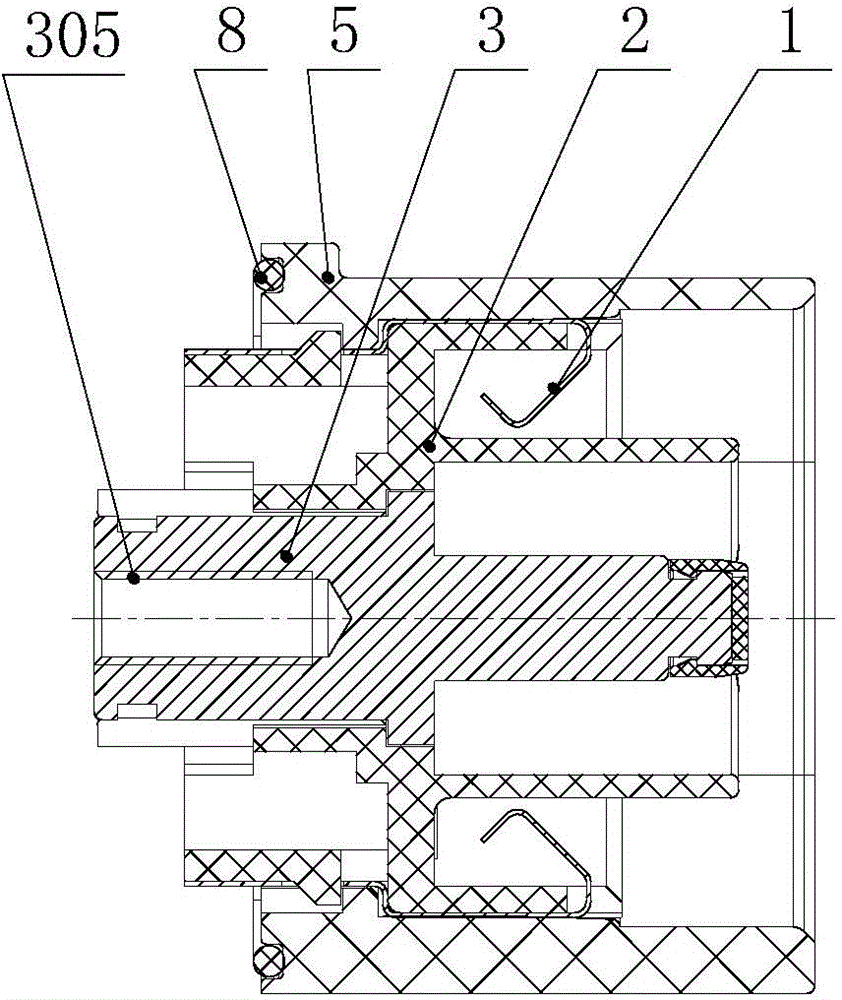

[0028] Embodiment 1: a kind of shielding MCU bus socket, such as Figures 1 to 5 As shown, it includes a shielding cover 1, a pin mounting plate 2, a pin assembly 3, a screw sleeve 4, a sheath 6, a signal hole 7, a gasket 8 and a plastic socket housing 5, and the shielding cover 1 is located on the socket housing 5 Between the pin mounting plate 2 and the shielding cover 1 covered on the surface of the pin mounting plate 2, the socket housing 5, the shielding cover 1 and the pin mounting plate 2 are engaged with each other, and the pin mounting plate 2 Anti-touch wall 204, pin assembly 3 and sheath 6 are provided inside, and signal hole 7 for conduction signal is provided in said sheath 6; use all-plastic shell as the shell of socket, reduce the quality of socket; The plastic shell does not need a metal shell as an installation and support member, which can reduce the volume of the socket. The shielding function is realized by assembling the shielding cover 1 in the socket she...

Embodiment 2

[0035] Embodiment 2: as Image 6 As shown, it is a shielded MCU bus socket with three cores, the pin assembly 3, the pin fixing hole 205, the anti-touch wall 204, and the pin fixing buckle 206 are three groups, and the rest are the same as in the first embodiment.

[0036] All parts with complex structures in the present invention can be formed by molds, which can better ensure product consistency, maximize production efficiency, and reduce production costs. It is suitable for new energy vehicles, industrial equipment, urban rail and other industries. Electrical connectors, especially suitable for shielded MCU bus sockets for new energy vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com