Method for dry protection of reactor core of dry reactor

A reactor and drying technology, which is applied in the fields of reactors, manufacturing reactors, processing of building materials, etc., can solve the problems of inconvenient drying operation, and achieve the effect of simple and convenient operation, saving construction period and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for drying reactor core dry protection of the present invention comprises the following steps:

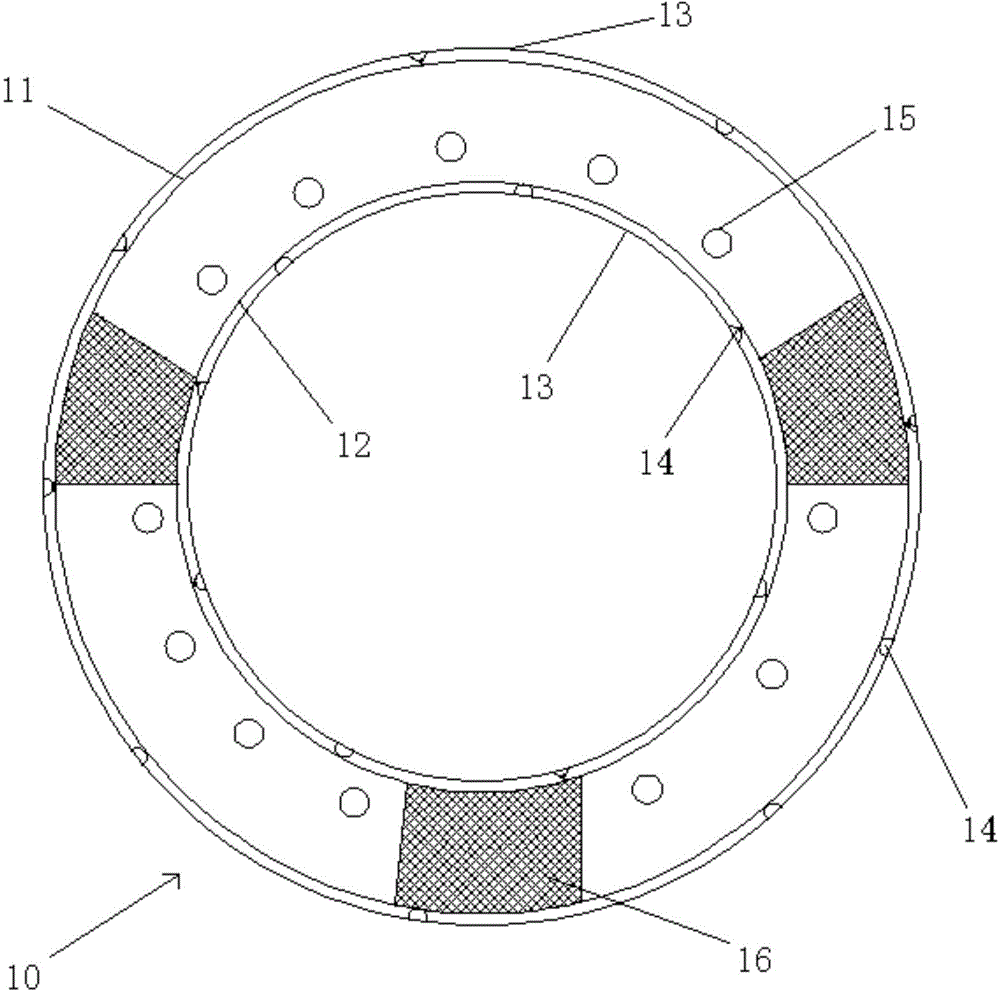

[0029] (1) if figure 2 As shown, when the dry protection 10 is poured with concrete, the internal heater 15 is embedded in the dry protection. The number of the internal heaters 15 is several, and the internal heaters 15 are evenly distributed in the dry protection 10, so as to Dry protection 10 heating;

[0030] (2) Take the concrete in step (1) as the test block, and pre-embed the internal heater in the test block. The test block can be a cubic structure, and the number of internal heaters pre-embedded in the test block is several , the internal heater is evenly distributed in the test block, so as to be able to heat the test block evenly; the test block is equivalent to the sample of concrete poured into the dry protection 10, in the following steps, the processing method of the test block is the same as that of the dry The processing method of the protectio...

Embodiment 2

[0039] The method for drying reactor core dry protection of the present invention comprises the following steps:

[0040] (1) if figure 2As shown, when the dry protection 10 is poured with concrete, the internal heater 15 is embedded in the dry protection. The number of the internal heaters 15 is several, and the internal heaters 15 are evenly distributed in the dry protection 10, so as to Dry protection 10 heating;

[0041] (2) Take the concrete in step (1) as the test block, and pre-embed the internal heater in the test block. The test block can be a cubic structure, and the number of internal heaters pre-embedded in the test block is several , the internal heater is evenly distributed in the test block, so as to be able to heat the test block evenly; the test block is equivalent to the sample of concrete poured into the dry protection 10, in the following steps, the processing method of the test block is the same as that of the dry The processing method of the protection...

Embodiment 3

[0050] The method for drying reactor core dry protection of the present invention comprises the following steps:

[0051] (1) if figure 2 As shown, when the dry protection 10 is poured with concrete, the internal heater 15 is embedded in the dry protection. The number of the internal heaters 15 is several, and the internal heaters 15 are evenly distributed in the dry protection 10, so as to Dry protection 10 heating;

[0052] (2) Take the concrete in step (1) as the test block, and pre-embed the internal heater in the test block. The test block can be a cubic structure, and the number of internal heaters pre-embedded in the test block is several , the internal heater is evenly distributed in the test block, so as to be able to heat the test block evenly; the test block is equivalent to the sample of concrete poured into the dry protection 10, in the following steps, the processing method of the test block is the same as that of the dry The processing method of the protectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com