A loading test device

A loading test device and horizontal loading technology, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, etc., can solve the problems of high energy consumption, high price, high test cost, etc. , to achieve the effect of ensuring accurate distribution and solving the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

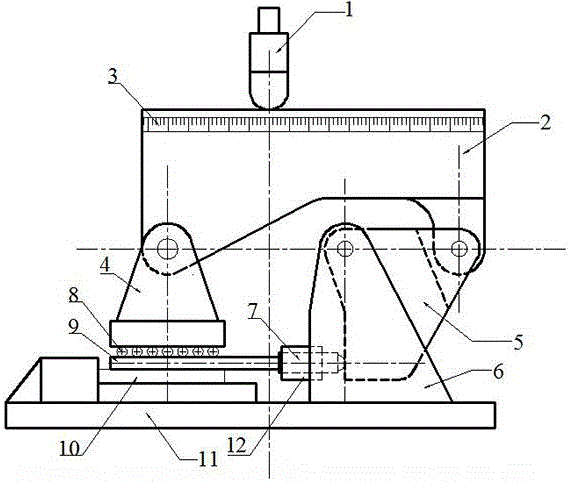

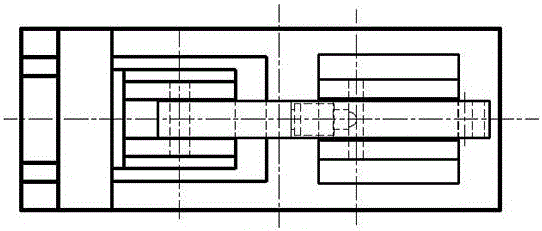

[0015] Such as figure 1 , figure 2 As shown, the present invention mainly includes a base 11, a steering plate 5, a load distribution beam 2, a ballast head 4, and a horizontal loading plate 9; one end of the base is provided with a fixed blocking plate, and the other end is provided with a fixed U-shaped horizontal support 6 The opening direction of the horizontal support 6 is far away from the blocking plate, and the convex portion 12 of the opening is provided on the horizontal support near the blocking plate surface, and the long cylindrical horizontal loading head 7 is placed in the convex portion 12, and the length of the convex portion 12 is less than The length of the horizontal loading head 7; one end of the steering plate 5 is hinged with the upper ends of the two wings of the horizontal support 6, and the other end of the steering plate 5 is hinged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com