Fixed grate and incineration system applying same

A technology for fixing grate and grate, applied in the field of incineration system, can solve the problems of incinerator manufacturer's influence on production interests, affecting incineration efficiency, poor ventilation of main combustion chamber, etc., to improve incineration efficiency, ensure incineration temperature, ensure constant and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

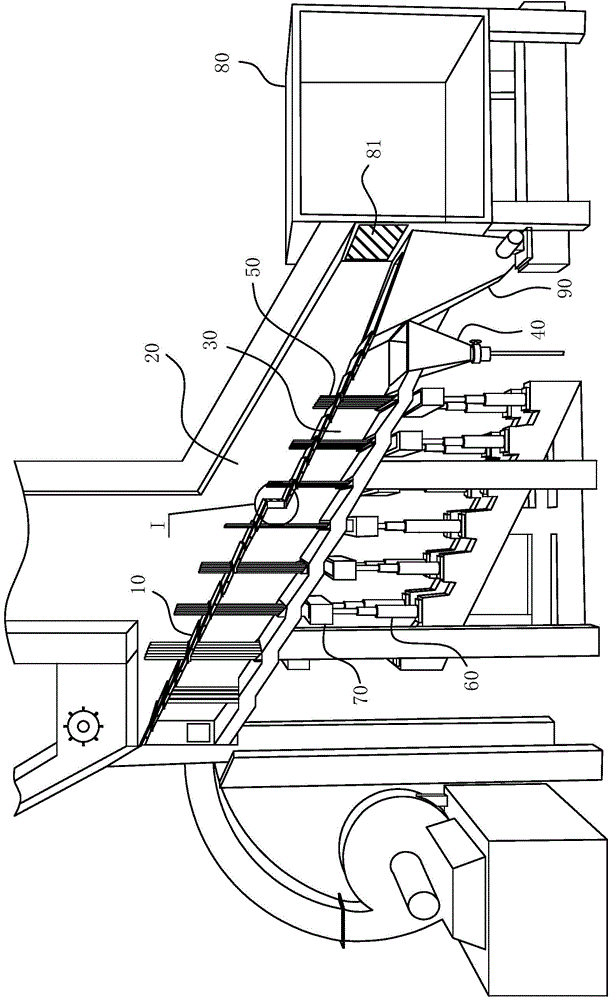

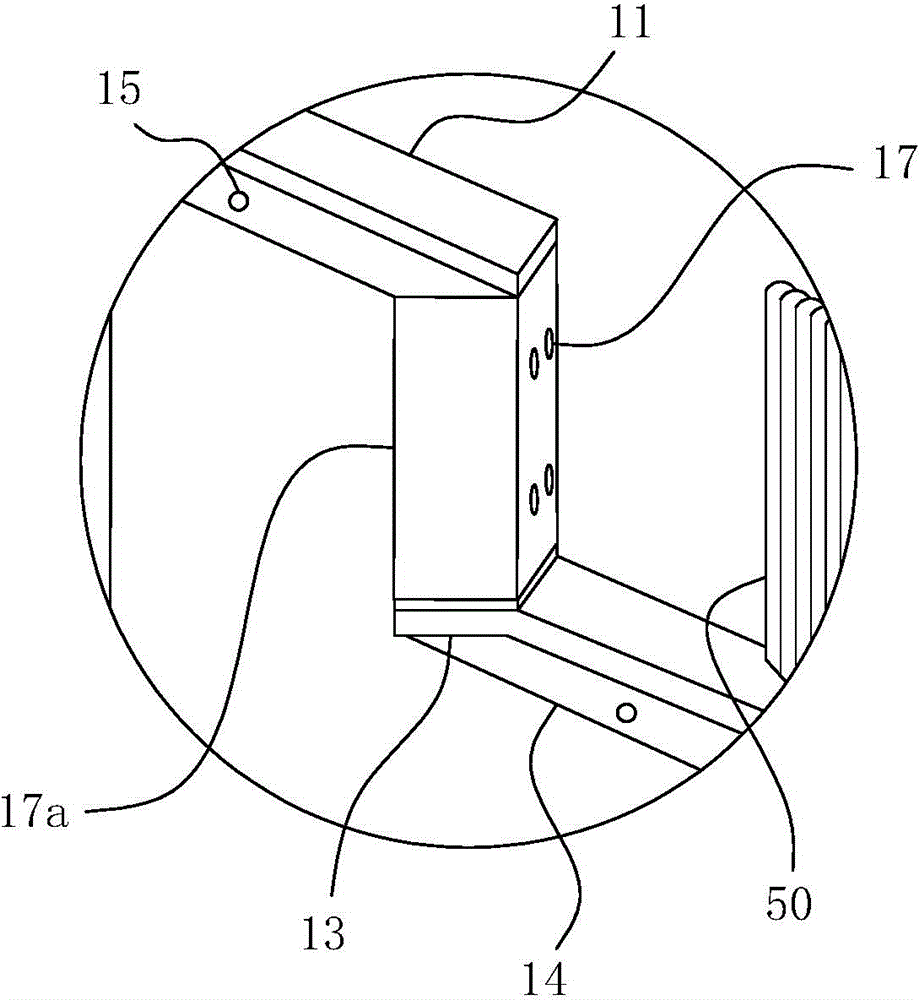

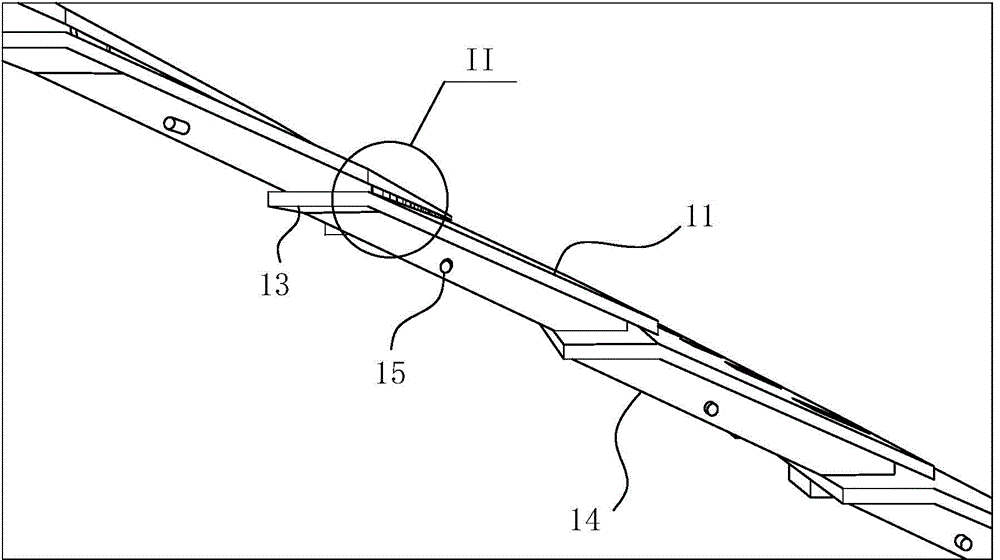

[0038] For ease of understanding, combined here Figure 1-7 The specific implementation structure of the present invention is further described as follows:

[0039] The actual structure of the present invention is as Figure 1-7 As shown, it includes a main combustion chamber arranged in the furnace body, and the main combustion chamber is divided into a combustion chamber 20 and a hot air chamber 30 by a fixed fire grate 10 . Wherein the hot air chamber 30 realizes its air supply function by an external fan, and achieves the air supply and incineration effect on the materials in the combustion chamber 20 through the ventilation holes 12 on the fixed fire grate 10 . The fixed grate 10 can be regarded as composed of a plurality of grate units arranged side by side in sequence along the material traveling direction. Each grate unit includes a rectangular grate plate 11 arranged obliquely on the plate surface and an extension plate 13 fixed on the edge of the upper plate of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com