A gear selection and shifting actuator of a mechanical automatic gearbox for a vehicle

A shifting actuator and automatic shifting technology, applied in the direction of mechanical equipment, transmission control, components with teeth, etc., can solve problems such as off-gear, high reverse efficiency, jumping gears, etc., and achieve smooth torque and control accuracy The effect of high and low processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the technical solution of the present invention will be further introduced below in conjunction with the accompanying drawings of the description:

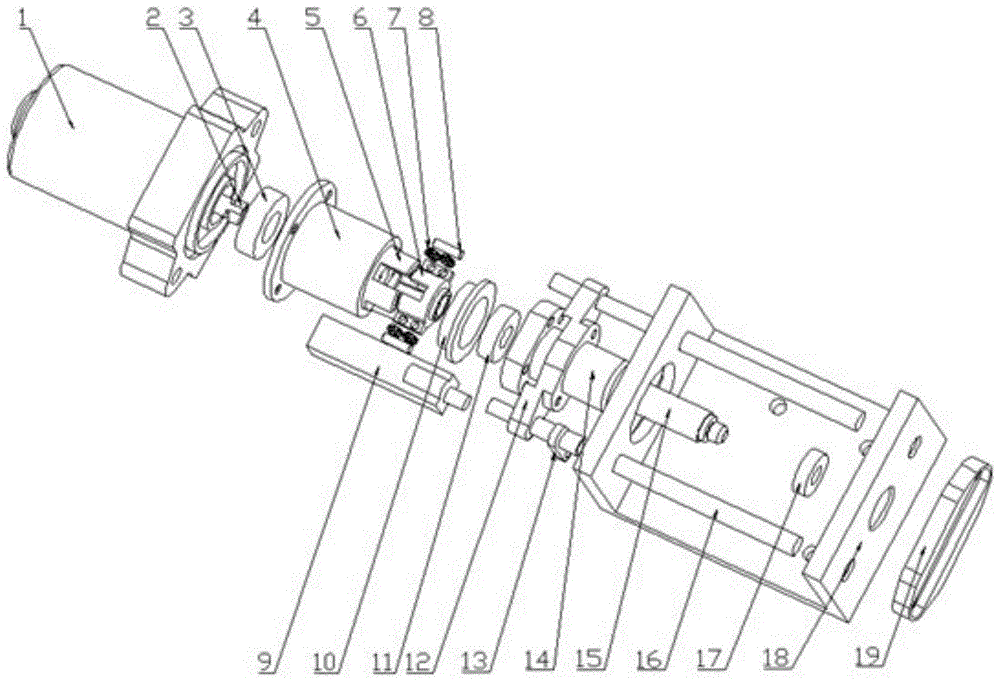

[0032] Such as figure 1 As shown, a gear selection and shifting actuator of a mechanical automatic transmission for a vehicle includes a brushless DC motor 1, a reverse drive bidirectional backstop, a ball screw nut 14, a ball screw screw 15, a push-pull rod 16, and a support frame 18 and baffle plate 19.

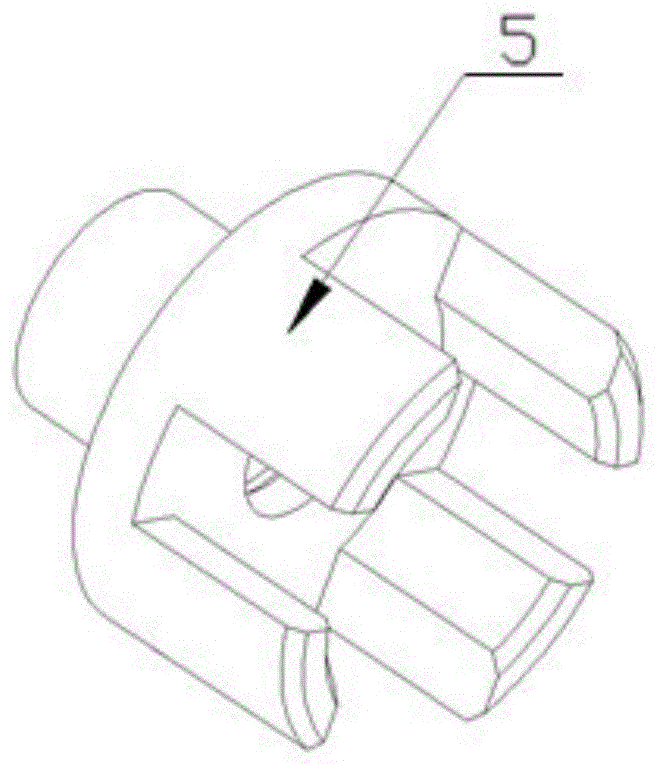

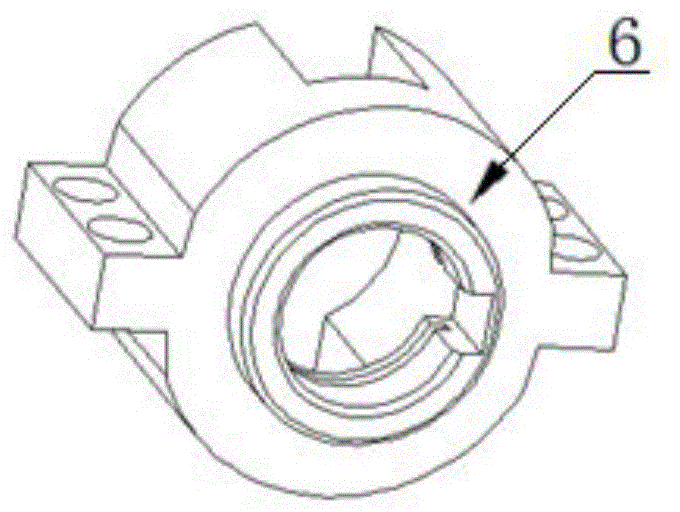

[0033] Wherein, the anti-transmission two-way backstop is composed of an outer ring 4, an annular shift fork 5, a planetary wheel 6, a spring 7 and a roller 8.

[0034] The bracket 18 is groove-shaped, the brushless DC motor 1 is fixed on the outside of one end of the bracket 18, the reverse drive bidirectional backstop is located inside the groove of the bracket 18, and the outer ring 4 is fixedly installed on the inner wall of the groove of the bracket 18. The ring shift fork 5 is sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com