Fire-retardant water-based dual-component top-coat paint for wood ware, and preparation method of paint

A two-component, clear topcoat technology, applied in the direction of fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of water-based wood coatings that cannot be fire-resistant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A fire-resistant water-based two-component clear finish for wood, the fire-resistant water-based two-component clear finish for wood includes components A and B,

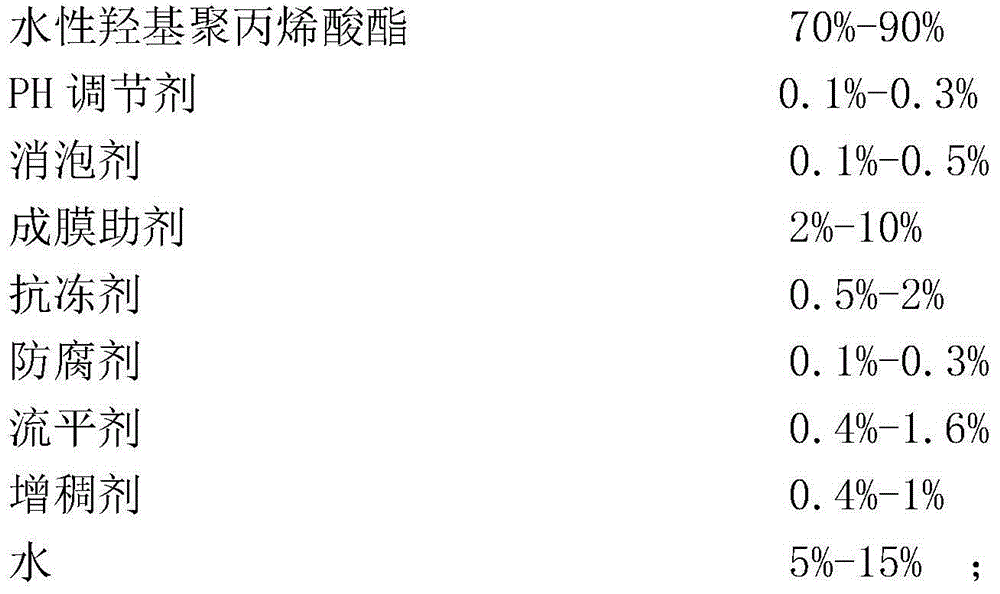

[0024] Wherein, component A includes the following specific ingredients and the weight percentages of each ingredient are as follows:

[0025]

[0026]

[0027] Among them, component B includes: Bayer XP2487-1;

[0028] The ratio of component A and component B by weight is as follows: A:B=100:20.

[0029] The leveling agent includes BYK346 leveling agent with a weight percentage of 0.2%-0.8% and Rohm and Haas RM2020 with a weight percentage of 0.2%-0.8%.

[0030] The water-based hydroxyl polyacrylate is Bayer A2651 resin; the pH regulator is Angus APM-95PH regulator; the defoamer is Henkel NXZ defoamer; the film-forming aid is DPNB film-forming Auxiliary agent; The antifreeze agent is propylene glycol antifreeze agent; The preservative is Thor R-S preservative; The thickener is Rohm and Haas RM8W.

...

Embodiment 2

[0040] A fire-resistant water-based two-component clear finish for wood, the fire-resistant water-based two-component clear finish for wood includes components A and B,

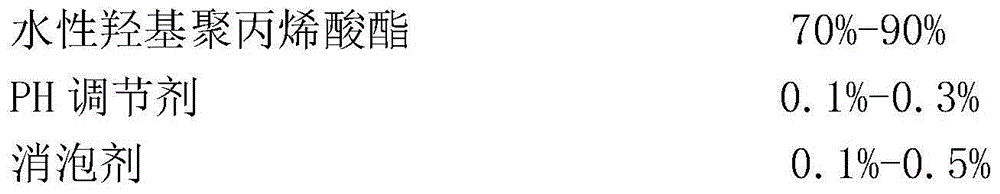

[0041] Wherein, component A includes the following specific ingredients and the weight percentages of each ingredient are as follows:

[0042]

[0043]

[0044] Among them, component B includes: Bayer XP2487-1;

[0045] The ratio of component A and component B by weight is as follows: A:B=100:20.

[0046] The leveling agent includes BYK346 leveling agent with a weight percentage of 0.5% and Rohm and Haas RM2020 with a weight percentage of 0.5%.

[0047] The water-based hydroxyl polyacrylate is Bayer A2651 resin; the pH regulator is Angus APM-95PH regulator; the defoamer is Henkel NXZ defoamer; the film-forming aid is DPNB film-forming Auxiliary agent; The antifreeze agent is propylene glycol antifreeze agent; The preservative is Thor R-S preservative; The thickener is Rohm and Haas RM8W.

[0048] A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com