A frame structure of inner tension tail of plate chain bucket elevator

A frame structure, bucket elevator technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of tail shaft labyrinth friction, equipment wear, lack of frame structure tail shaft, etc., and achieve the effect of preventing mutual friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

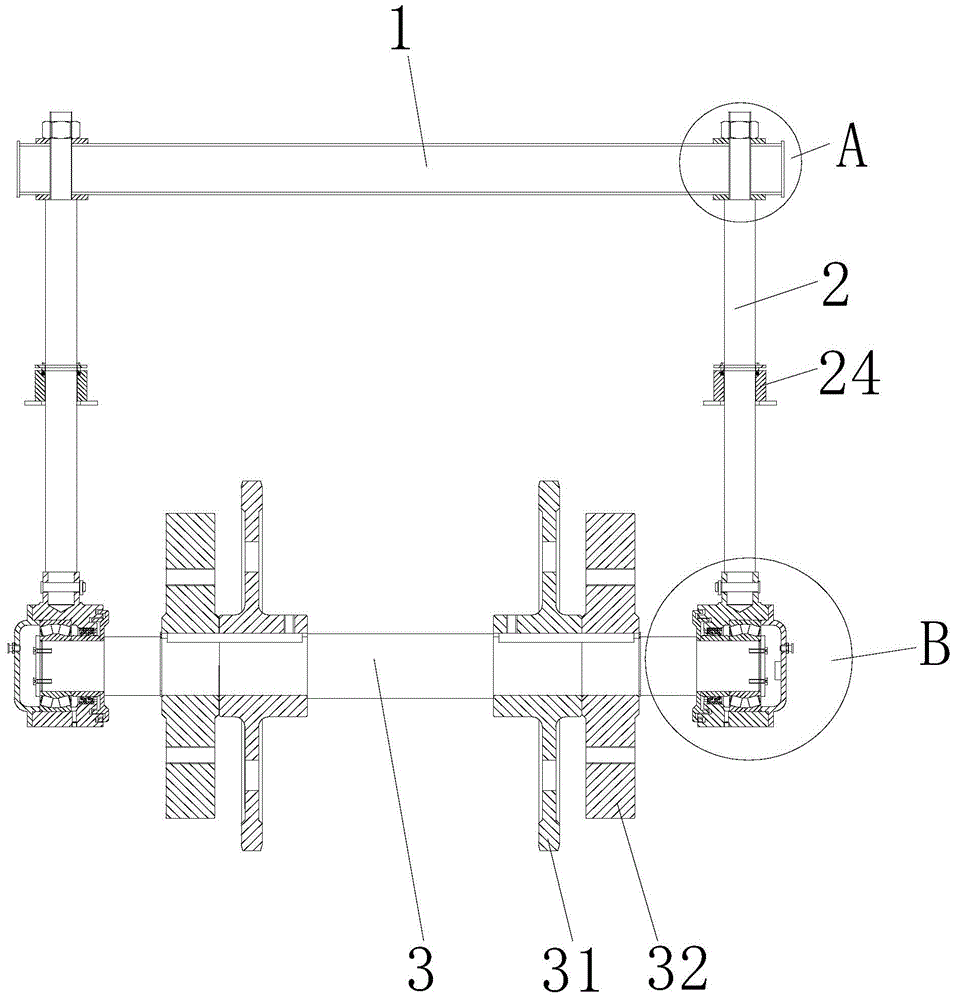

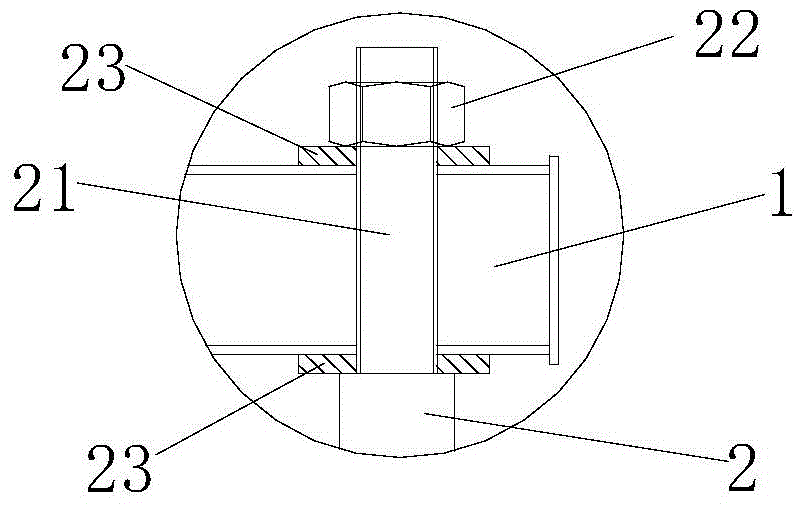

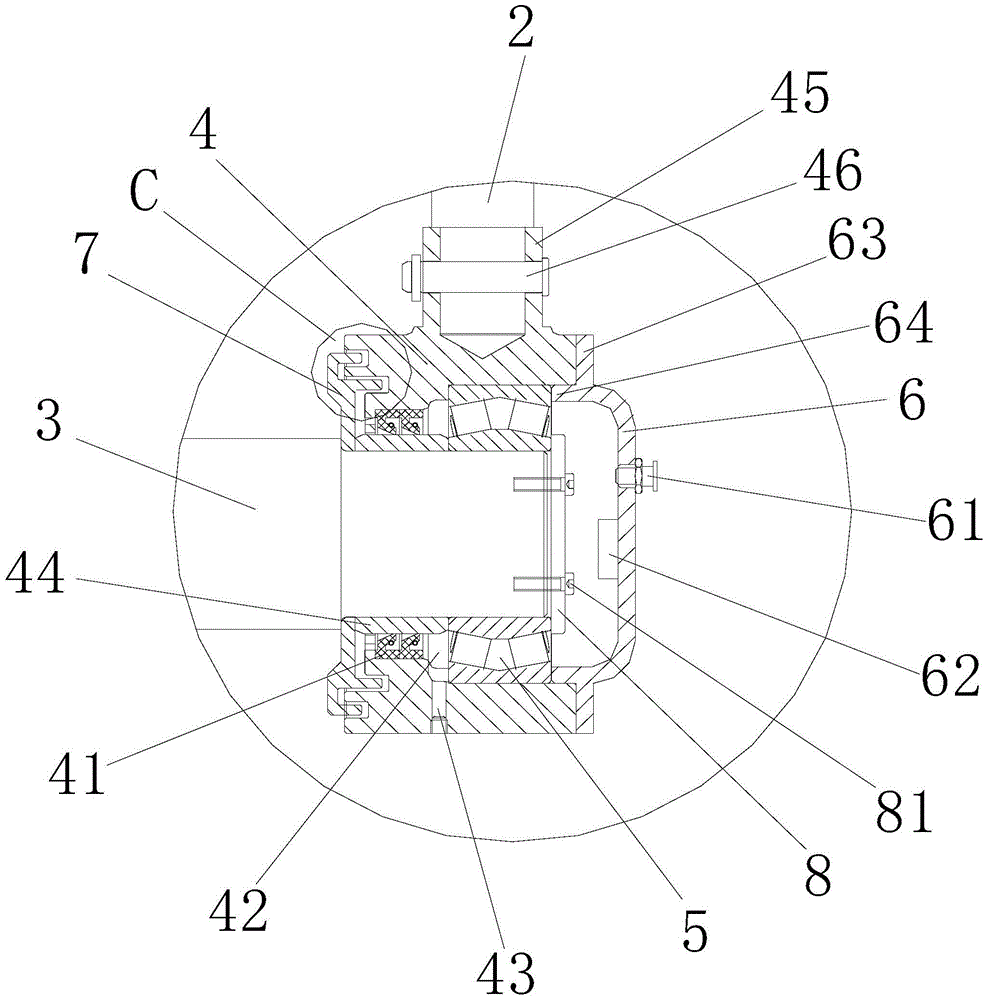

[0021] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention is a frame structure of the internal tension tail of a plate chain bucket elevator, including a cross bar 1, a connecting rod 2, a tail shaft 3, a tail wheel 31, a counterweight wheel 32, a bearing seat 4 and a ball bearing 5. Both ends of the bar 1 are equipped with connecting rods 2, the cross bar 1 and the two connecting rods 2 form a frame structure, the two ends of the tail shaft 3 are respectively connected with the connecting rods 2, and two symmetrically installed on the tail shaft 3 Tail wheel 31, two counterweight wheels 32 are symmetrically installed on the tail shaft 3, the counter weight wheels 32 are located on one side of the tail wheel 31, ball bearings 5 are installed at the end of the tail shaft 3, and the ball bearings 5 are installed on the bearing housing 4 Inside, an end cover 6 is installed on one side of the bearing seat 4, a labyrinth seal ring 7 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com