A gas channel design method for composite material cavity structure airbag molding

A composite material and design method technology, applied in the field of advanced composite material manufacturing, can solve the problems of easy damage and air leakage of airbags, high manufacturing cost of airbags, uneven pressure of parts, etc., to eliminate the possibility of damage and air leakage , Reduce molding difficulty and risk, improve pass rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

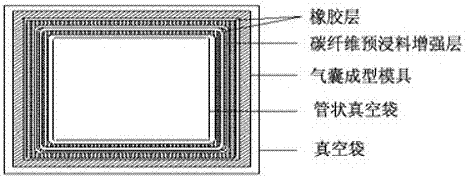

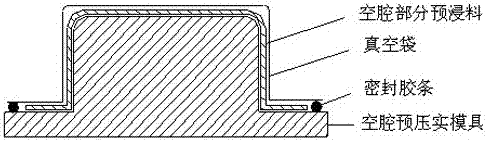

[0023] The present invention abandons the metal air nozzle and adopts the method of opening the end to form the airbag. After the airbag is formed, it cooperates with the corresponding mold design and the scheme of making the vacuum bag, which not only can better ensure the consistent pressure inside and outside the airbag, but also greatly prolongs the The service life of the airbag. The detailed process is as follows:

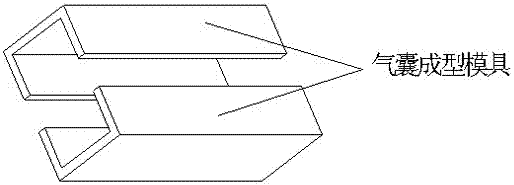

[0024] (1) Process a set of airbag forming molds that match the internal dimensions of the cavity structure. The airbag forming molds are divided into upper and lower parts, and there is a cooperative relationship between them, such as figure 1 ;

[0025] (2) Use two airbag forming molds respectively to pave the airbag tooling. The airbag tooling uses rubber as the main material, and the rubber is laid layer by layer on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com