Double-layer net mill pressing mechanism and double-layer net mill press juicer

A double-layer mesh and double-layer technology, which is applied in household machinery for filtering food, household utensils, applications, etc., can solve the problem of inability to have grinding and cutting functions at the same time, poor grinding effect of wall knives and rotors, and easy processing of fruit and vegetable raw materials. Sliding to the bottom of the strainer, etc., to achieve the effects of food safety, significant juicing effect, and improved squeezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

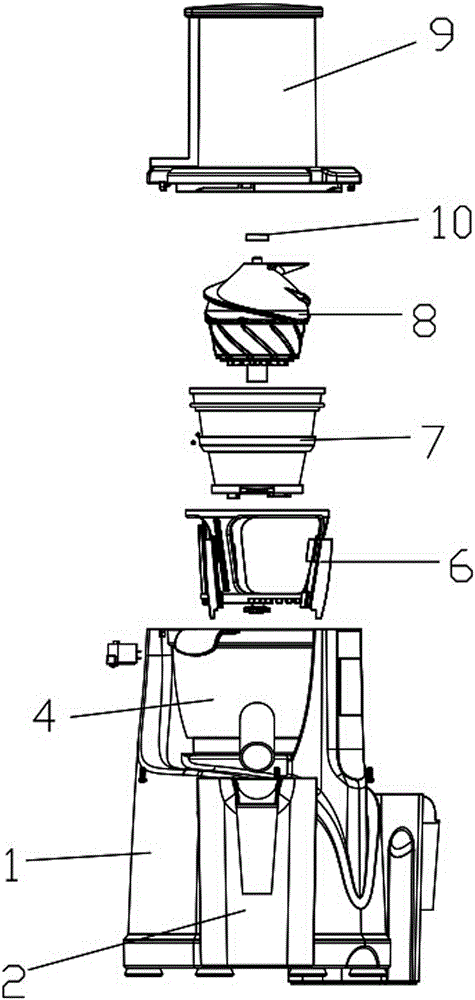

[0039] Embodiment one, with reference to Figure 1 to Figure 6 , the double-layer net grinding mechanism of the present embodiment includes a filter screen 7 with an opening on the top and a rotor 8 positioned inside the filter screen 7, and the filter screen 7 is a double-layer filter screen structure, such as figure 1 As shown, it includes an upper filter screen 21 and a lower filter screen 22, the inner diameter of the lower filter screen 22 is less than the inner diameter of the upper filter screen 21, and the upper filter screen 21 and the lower layer filter screen 22 are connected and transitioned by the filter screen grinding surface 16. This implementation The filter screen grinding surface 16 of example is parallel to the horizontal plane. In order to ensure the grinding effect, the inner side wall of the upper filter screen 21 is provided with an upper wall knife 24, the inner side wall of the lower filter screen 22 is provided with a lower wall knife 25, the inner s...

Embodiment 2

[0043] Embodiment two, refer to Figure 7 , the difference between the second embodiment and the first embodiment is that the top of the upper cover 9 is a large-diameter material inlet, and a pressure head rod 27 that can be inserted and taken out for pressing down the material is provided in the large-diameter material inlet. The motor box 1 is provided with a touch switch 28 for normal operation of the machine, the touch switch 28 is fixed by the switch platen, and the outer surface of the upper cover 9 is provided with a sliding rod for moving the touch switch 28 to make it closed and conducting Assembly 29, the sliding rod assembly 29 is also provided with an elastic assembly 30 for resetting the sliding rod assembly 29. After the sliding rod assembly 29 is reset, the touch switch 28 is reset and disconnected at the same time, and the outer surface of the pressure head rod 27 is erected. Slide bar assembly 29 active guide strips. Because there is a safety problem in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com