Salty pumpkin preserves and preparation method thereof

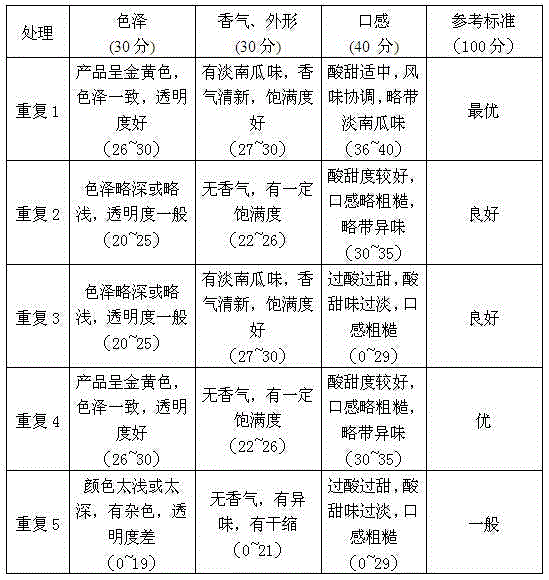

A technology of preserved pumpkin fruit and salty taste, applied in confectionery, confectionery industry, food science and other directions, can solve the problem of low antibacterial effect and low sweetness, and achieve the effect of good transparency, high antibacterial effect and consistent color and luster.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

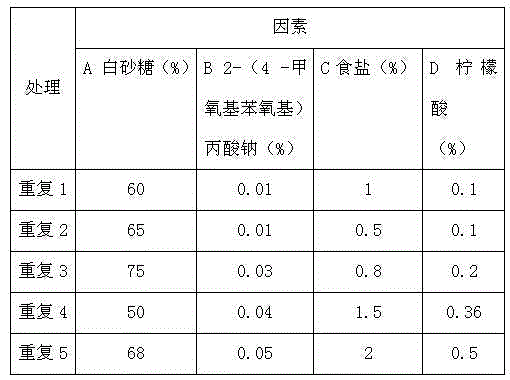

[0024] A salty preserved pumpkin, comprising pumpkin strips, ingredient liquid and mixed liquid; said ingredient liquid includes 60% sugar, 0.5-2% salt, 0.3-0.5% citric acid and 2-(4-methoxyphenoxy) ) Sodium propionate 0.01-0.05%; the mixed solution includes calcium chloride 0.1-0.2%, sodium chloride 0.5-1%, and citric acid 0.1-0.2%.

[0025] A preparation method of salty pumpkin preserved fruit includes the following steps:

[0026] 1) Material selection: Choose fully mature old pumpkins, fresh, free of pests and diseases, no mechanical damage, strong flavor and golden color;

[0027] 2) Washing, peeling and sun drying: Wash the surface of the pumpkin with clean water and peel it. Finally, the pumpkin is cut open, peeled and seeded, and dried for two days;

[0028] 3) Slicing: Cut the processed pumpkin strips into strips or granules with a thickness of about 1cm as needed;

[0029] 4) Prepare the mixed solution: the main raw materials are calcium chloride 0.15%, sodium chloride 1%, an...

Embodiment 2

[0036] A method for preparing salty pumpkin preserved fruits as described in embodiment 1, wherein:

[0037] The mixed solution described in step 4) is made up of 0.15% calcium chloride, 1% sodium chloride, and 0.1% citric acid;

[0038] The mixing time of the mixed solution mentioned in step 5) is 9h;

[0039] The ingredients mentioned in step 6) are prepared with 60% white sugar, 0.01% sodium 2-(4-methoxyphenoxy)propionate, 1% salt, and 0.1% citric acid;

[0040] Step 7): Immerse the raw materials in a vacuum pot containing 20% sugar liquid, evacuate for 55 minutes, depressurize and immerse for 8 hours, then take out the raw materials, put them into a vacuum pot containing 50% sugar liquid, evacuate for 60 minutes , Decompression, immersion for 8h, and finally evacuated in the 60% sugar-containing ingredient liquid, immersed to the end;

[0041] The drying temperature mentioned in step 8) is 73°C.

Embodiment 3

[0043] A method for preparing salty pumpkin preserved fruits as described in embodiment 1, wherein:

[0044] The mixed solution described in step 4) is prepared with 0.13% calcium chloride, 0.7% sodium chloride, and 0.2% citric acid;

[0045] Step 5) The mixing time of the mixed solution is 10h;

[0046] The ingredients mentioned in step 6) are prepared with 65% white sugar, 0.03% sodium 2-(4-methoxyphenoxy)propionate, 0.8% salt, and 0.2% citric acid;

[0047] Step 7): Immerse the raw materials in a vacuum pot containing 35% sugar solution, evacuate for 60 minutes, depressurize and immerse for 8 hours, then take the raw materials out, put them into a vacuum pot containing 40% sugar solution, evacuate for 40 minutes , Decompression, immersion for 8h, and finally evacuated in the ingredient liquid containing 65% sugar, and immersed to the end;

[0048] The drying temperature mentioned in step 8) is 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com