Combustion pressure sensor

A technology of combustion pressure and sensors, applied in instruments, internal combustion engine testing, measuring devices, etc., can solve the problems of weakened bellows function, failure to detect combustion pressure, and obstruction of bellows shrinkage, so as to ensure installation strength, achieve stability and reliability performance, and the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

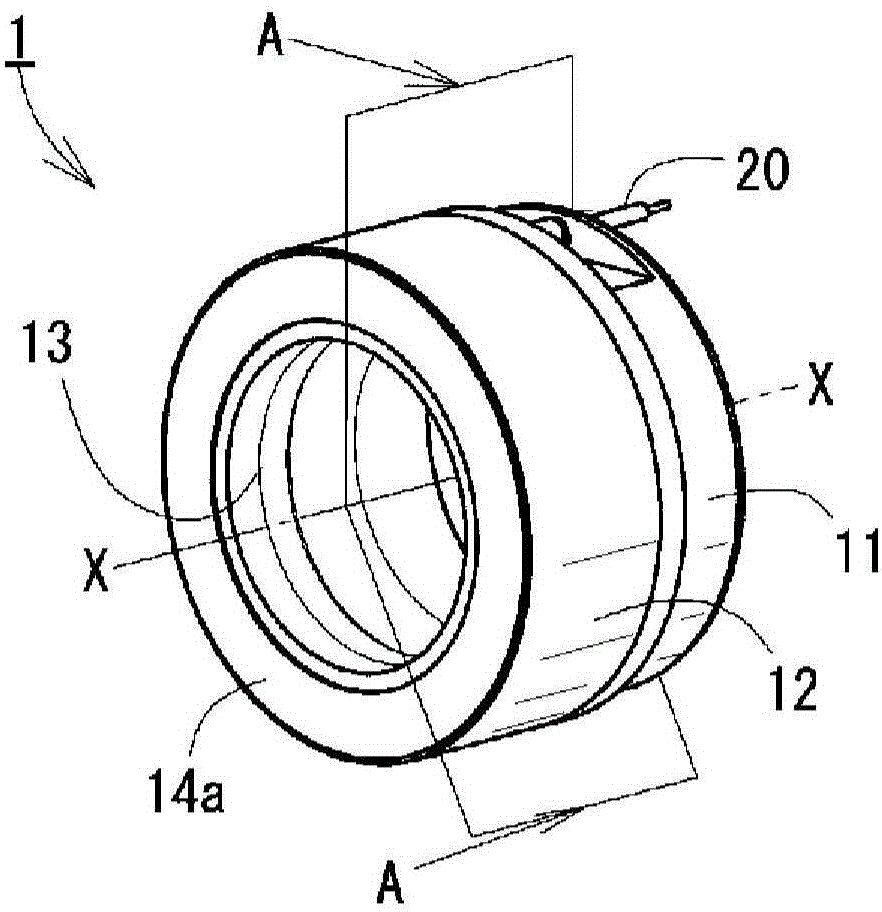

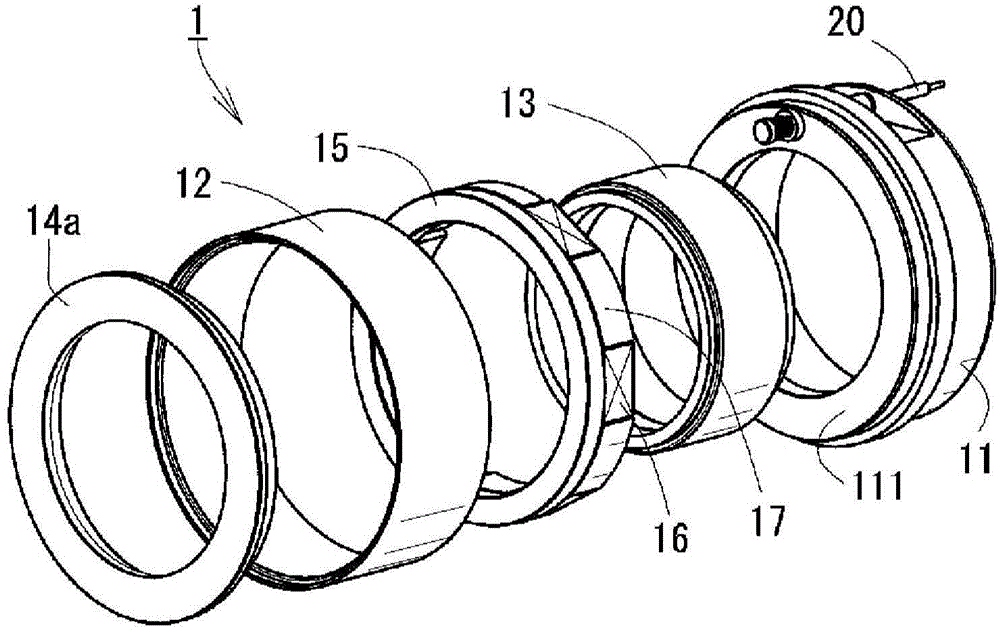

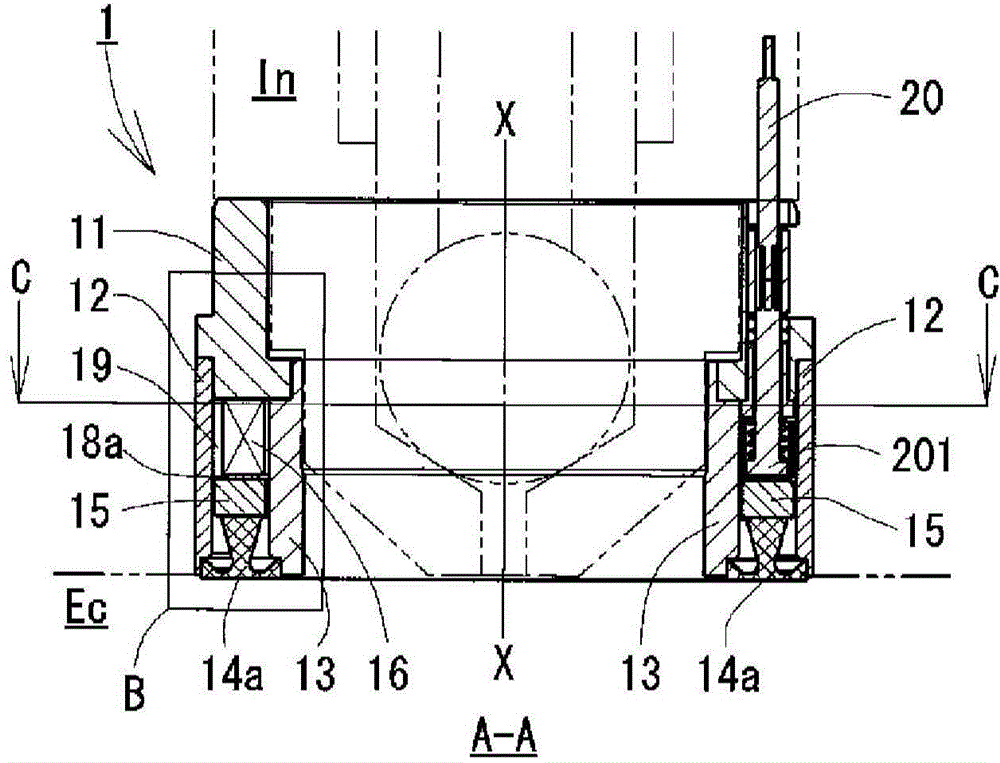

[0044] figure 1 is a perspective view showing the appearance of the combustion pressure sensor according to Embodiment 1 of the present invention, figure 2 is an exploded perspective view of the combustion pressure sensor, image 3 is along figure 1 The cross-sectional view of the A-A section in , the injector as a functional part is represented by an imaginary line (two-dot dash line), Figure 4 yes image 3 Partial enlarged cross-sectional view of Part B of Figure 5 is along image 3 Cutaway view of the C-C section in . In addition, the same code|symbol is attached|subjected to the same structural member in each figure, and overlapping description is abbreviate|omitted.

[0045] Below, through Figure 1 to Figure 5 The overall structure of the combustion pressure sensor according to Embodiment 1 will be described.

[0046] Such as figure 1 As shown, the combustion pressure sensor 1 according to Embodiment 1 of the present invention has a cylindrical shape with the...

Embodiment approach 2

[0068]Embodiment 2 is the same as Embodiment 1. It is a combustion pressure sensor composed of a ring-shaped cylinder that can be installed at the end of a functional component in the engine combustion chamber. The difference from Embodiment 1 is only the shape of the diaphragm. Regarding other The structural members are all the same.

[0069] Figure 6 is a perspective view showing the appearance of the combustion pressure sensor 2 according to Embodiment 2 of the present invention, Figure 7 is the same as that of Embodiment 1 Figure 4 The same partial enlarged cross-sectional view. In addition, the same code|symbol is attached|subjected to the same structural member in each figure, and overlapping description is abbreviate|omitted.

[0070] Below, through Figure 6 , Figure 7 The overall structure of the combustion pressure sensor according to Embodiment 2 will be described.

[0071] Such as Figure 6 As shown, the combustion pressure sensor 2 in Embodiment 2 of th...

Embodiment approach 3

[0076] Embodiment 3 is a combustion pressure sensor having the same shape as Embodiment 2. The difference from Embodiment 2 is that only part of the electrode layer is replaced with an electrode member, and all other structural members are the same.

[0077] Figure 8 is the same as that of Embodiment 2 Figure 7 The same partial enlarged cross-sectional view. In addition, the same code|symbol is attached|subjected to the same structural member in each figure, and overlapping description is abbreviate|omitted.

[0078] Below, through Figure 8 The overall structure of the combustion pressure sensor according to Embodiment 3 will be described.

[0079] Such as Figure 8 As shown, the difference from Embodiment 2 is that the electrode layer 18a is replaced with the electrode member 18b. That is, the electrode member 18b is composed of an insulating portion 181 and an electrode 182 formed on one surface of the insulating portion 181, such as FPC (Flexible printed circuits), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com