Device and method for horizontally loading fuel cell stacks

A fuel cell stack, horizontal technology, applied in the direction of fuel cells, fuel cell groups, circuits, etc., can solve the problems of poor uniformity, low performance, and time-wasting of the stack, and achieve the effect of stable stacking and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

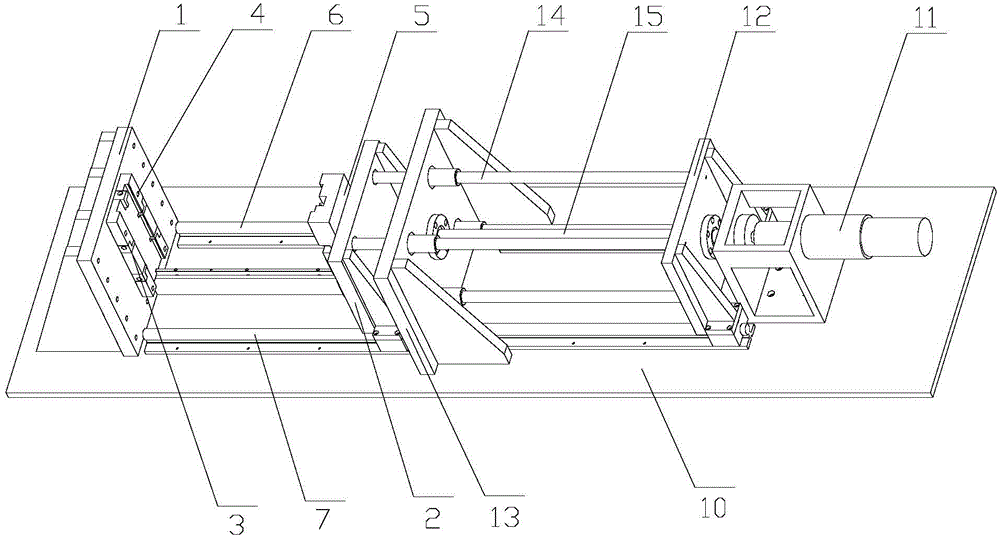

[0035] Embodiment 1: A device for horizontal stacking of fuel cell stacks, including a drive device, a stacking device and a horizontal base 10, the stacking device includes a first pressing plate 1 and a second pressing plate 2, and the stacking device is set On the horizontal base 10, the opposite surfaces of the first pressing plate 1 and the second pressing plate 2 are parallel to each other and perpendicular to the horizontal base 10, and the opposite surfaces of the first pressing plate 1 and the second pressing plate 2 are respectively arranged There are templates 3 matching the structure of the end plates, which are used to fix the end plates at both ends of the fuel cell; four positioning holes 4 are respectively arranged on the corresponding positions of the two templates 3, and the two positioning holes 4 are arranged symmetrically on the opposite sides of the template 3. side, used to install the outer positioning rod of the fuel cell stack; a pressure sensor 5 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com