Easy-to-pre-maintain LED (light-emitting diode) display screen module structure

A technology of LED display and module structure, which is applied in the direction of instruments, electrical components, casings/cabinets/drawer parts, etc., and can solve the problem of complex circuit of LED display panel, large volume and weight of display box , module component damage and other problems, to achieve the effect of ideal fixing effect, easy maintenance, and integrity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be explained in detail below in conjunction with specific drawings and embodiments.

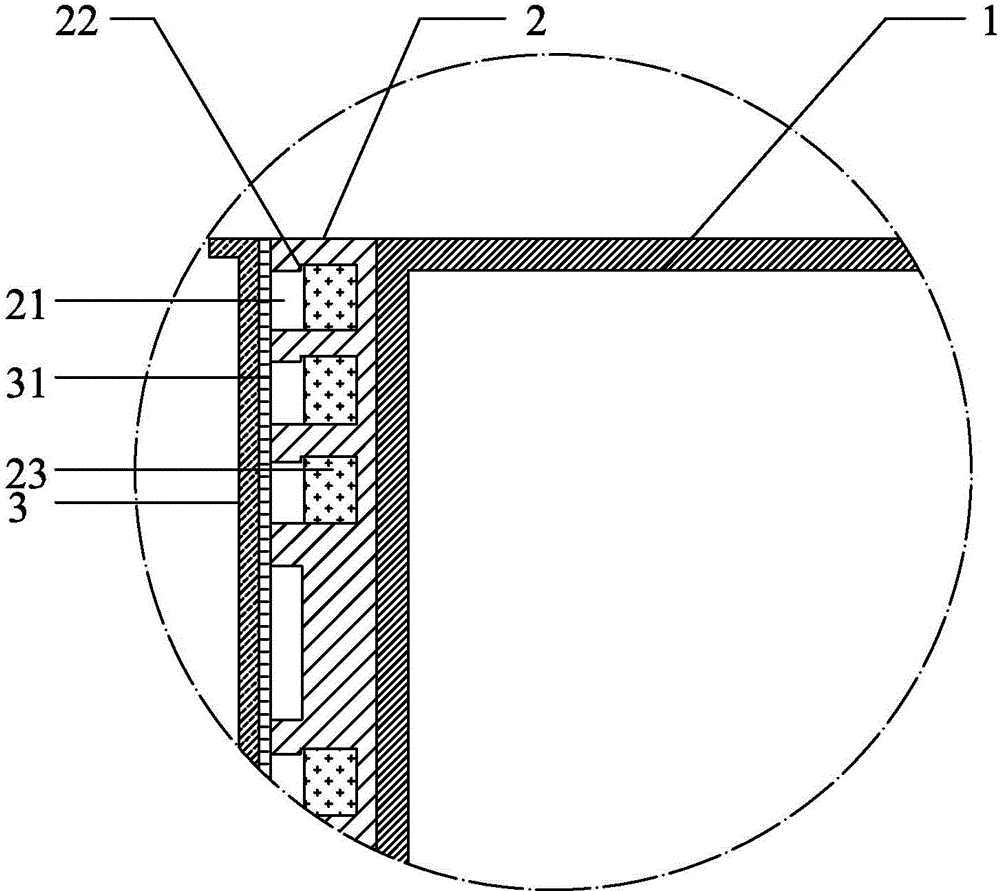

[0016] Such as figure 1 As shown, a LED display module structure that is easy to maintain in the front includes a module backplane 2 fixed to the LED display box 1, and a PCB board 3 is fixed on the front surface of the module backplane 2, so The PCB board 3 is provided with LED lights, and the module backboard 2 is provided with a plurality of accommodation spaces 21 for accommodating magnetic fixing parts 23, and at least one wall surface of the accommodation spaces 21 is provided with a locking limit The depth of the groove 22 is between 0.1-0.5 mm; an insulating layer 31 is also provided between the module backplane 2 and the PCB board 3 .

[0017] There are at least three accommodating spaces 21 arranged compactly in an array on the module backplane 2 .

[0018] The magnetic fixing part 23 is a block magnet capable of attracting each other with the LED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com