Screen laminating method and system

A bonding system and screen technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as low production efficiency, complex production process, unstable product quality, etc., to save operating time, Simple operation, the effect of improving productivity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

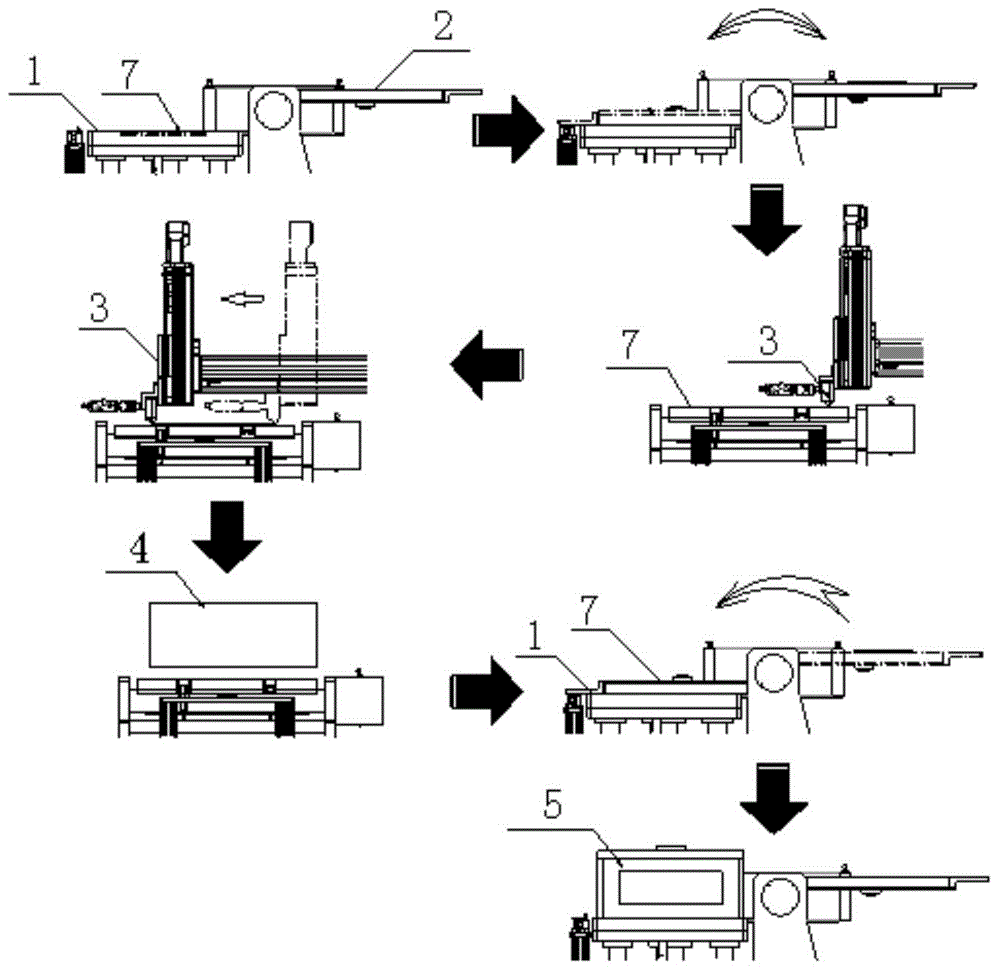

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

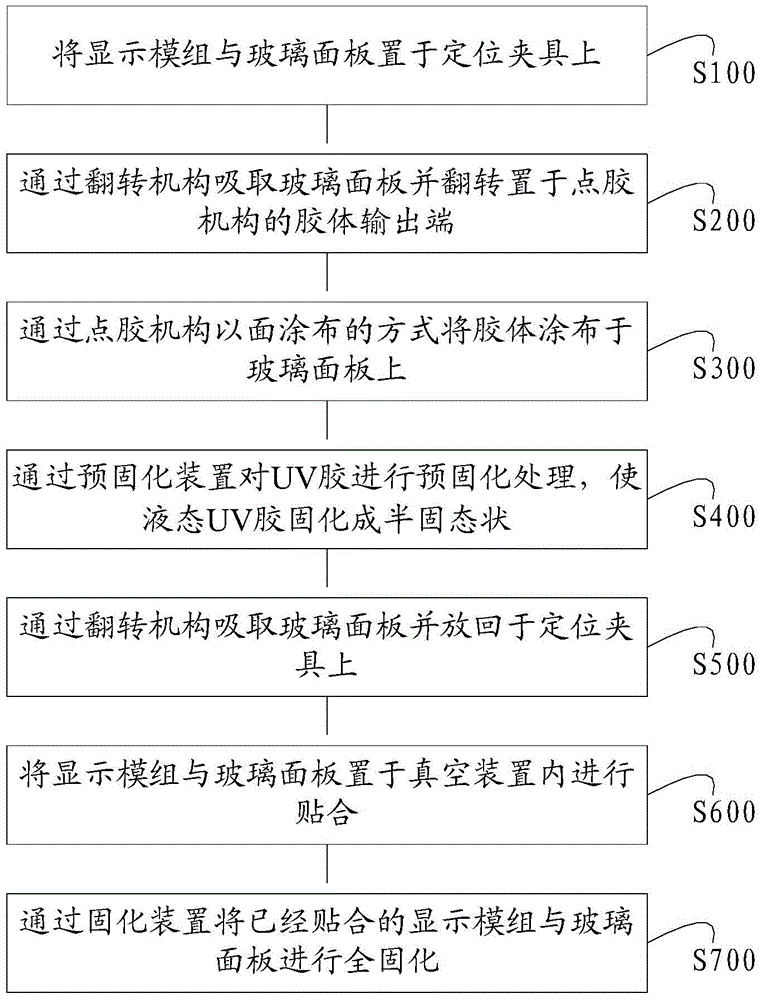

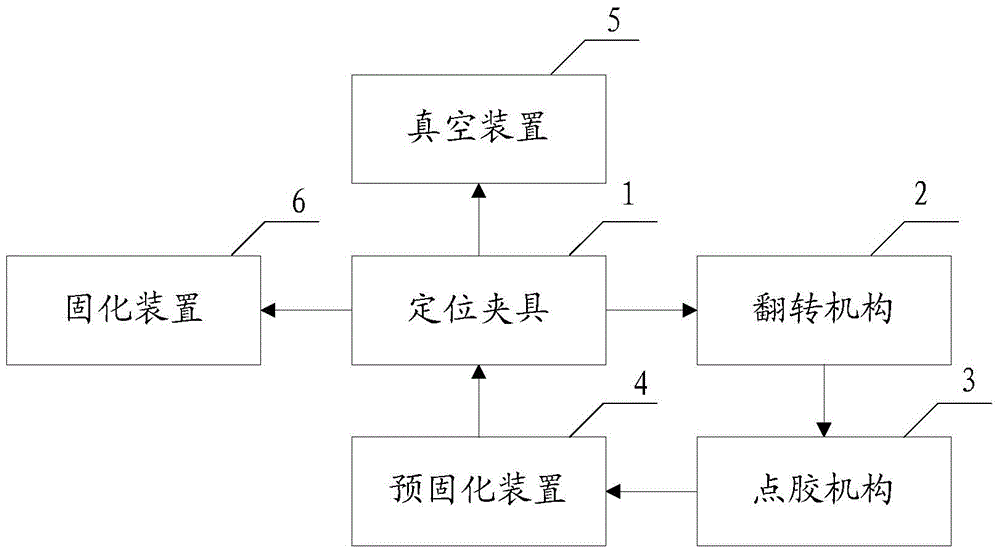

[0023] see figure 1 , is a flow chart of the screen pasting method according to the embodiment of the present invention. The screen bonding method of the embodiment of the present invention includes the following steps:

[0024] Step 100: placing the display module and the glass panel on the positioning fixture;

[0025] Step 200: absorb the glass panel through the turning mechanism, turn it over and place it on the glue output end of the glue dispensing mechanism;

[0026] Step 300: Coating the colloid on the glass panel by means of surface coating by a dispensing mechanism;

[0027] In step 300, the dispensing mechanism is a linear dispensing valve, and the linear dispensing valve applies glue through the method of surface coating, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com