Parallel high-power switching power supply

A high-power switch and parallel technology, which is applied in the direction of adjusting electrical variables, control/regulation systems, instruments, etc., can solve the problems of poor stability and reliability of parallel high-power power supplies, achieve good stability, improve stability, The effect of high working precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

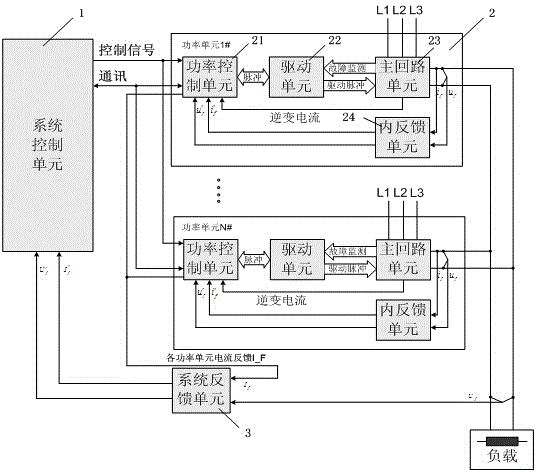

[0030] Embodiment 1: as figure 1 As shown, the purpose of the present invention is to provide a parallel high-power switching power supply with more effective coordination between the power units in parallel in order to overcome the problem of poor overall stability and reliability of the existing parallel high-power power supply. Including a system control unit 1 and more than one power unit 2 connected in parallel, the high-power switching power supply also includes a system feedback unit 3, the input end of the system feedback unit 3 is connected to the total output circuit of each power unit 2 connected in parallel, so The output terminal of the system feedback unit 2 is connected to the input terminal of the system control unit 1 , and the output terminal of the system control unit 1 is connected to the control terminals of each power unit 2 .

[0031]The system control unit 1 is used to output control signals to each power unit 2 connected in parallel to control the oper...

Embodiment 2

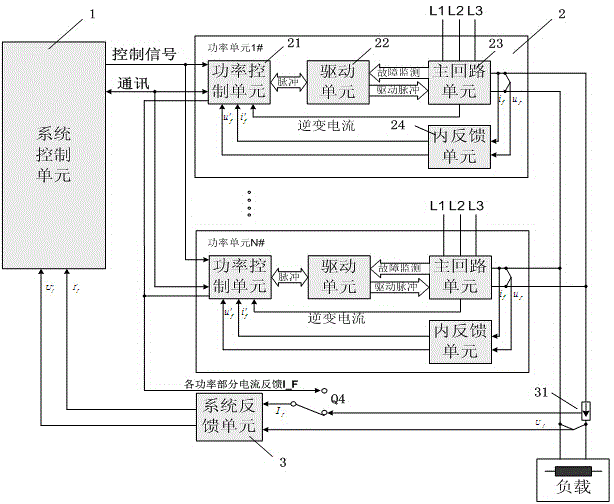

[0046] Embodiment 2: as figure 2 As shown, in this embodiment, in addition to the devices described in Embodiment 1, the system feedback unit also includes a shunt feedback unit or a Hall feedback unit 31, and the shunt feedback unit or Hall feedback unit 31 It is connected with the total output circuit of the power supply, and is used for collecting the total current value of each power unit.

[0047] The system feedback unit also includes a fourth selector switch Q4, and the fourth selector switch Q4 is used to select whether the system feedback unit adopts the feedback current superposition mode for total loop current feedback or adopts the shunt feedback mode or the Hall feedback mode for total loop current feedback. Loop current feedback.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com