Pipeline nondestructive testing device based on electric field fingerprint method

A technology of electric field fingerprinting and non-destructive testing, applied in the direction of material magnetic variables, etc., can solve the problems of easy corrosion of welded joints, damage of pipelines to be tested, and increase of device installation costs, so as to reduce construction costs, reduce test errors, and improve measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

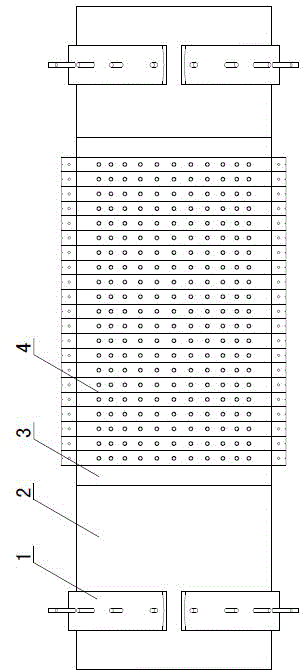

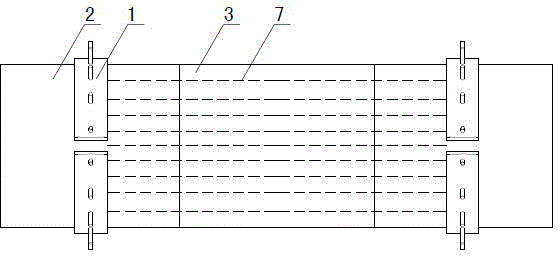

[0038] Figure 1~9 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~9 The present invention will be further described.

[0039] like figure 1 As shown, the non-destructive testing device based on the electric field fingerprint method includes a section of pipeline 2 to be tested, and multiple sets of capture electrode fixing sleeves 4 arranged in parallel on the surface of the pipeline to be tested 2, and each set of capture electrode fixing sleeves 4 is perpendicular to the pipeline to be tested. The direction of the axis is fixed with a plurality of capture electrodes, and the capture electrodes are in reliable contact with the surface of the pipeline 2 to be tested in a non-welding manner through the capture electrode fixing sleeve 4 . A voltage collection area 3 is formed on the surface of the pipeline 2 to be tested by multiple groups of capturing electrode fixing sleeves 4 arranged side by side. The voltage collection are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com