Salt cavern type gas storage cavity construction process oil-water interface detection method

A technology of oil-water interface and detection method, which is applied in the direction of displaying liquid level indicators through pressure measurement, can solve the problems of heavy workload, damage to cable armor and armor, and heavy workload, so as to simplify the process of measures and avoid cable damage or damage to the instrument, avoiding the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

[0043] This embodiment provides a method for detecting the oil-water interface in the cavity-building process of a salt-cavern gas storage, which includes the following steps:

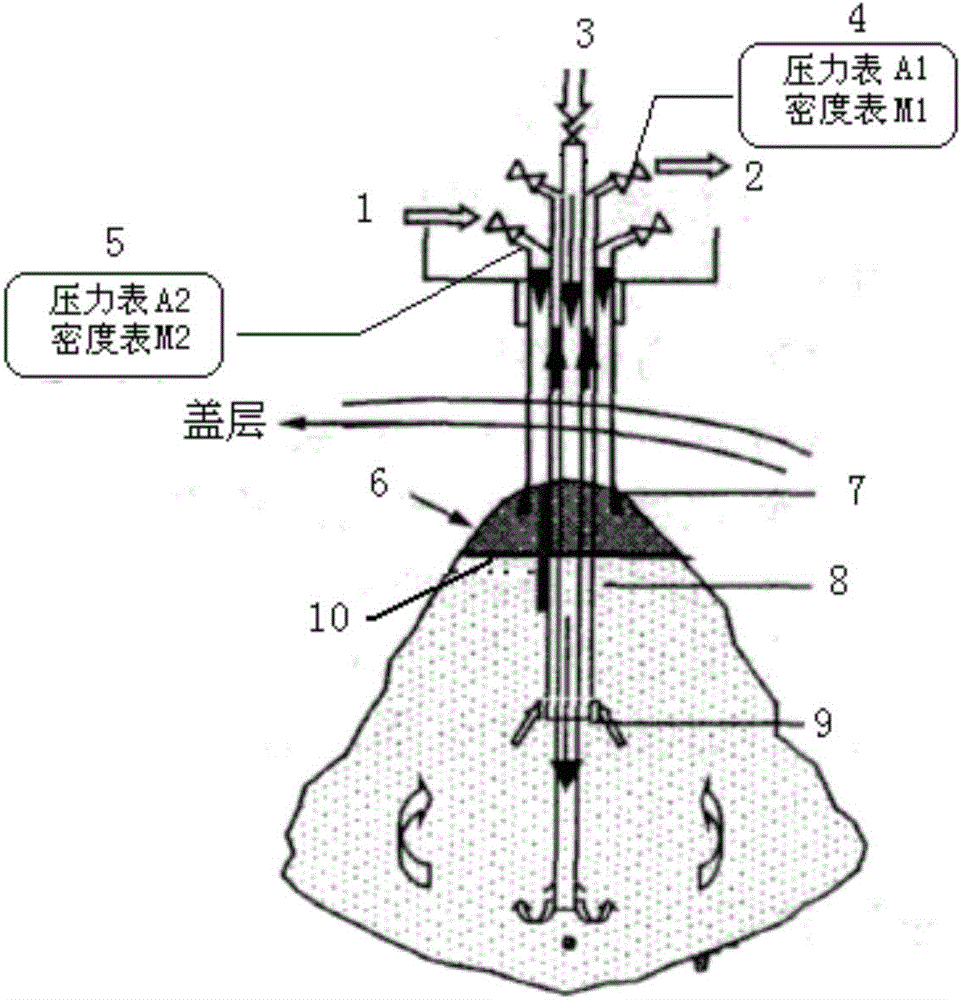

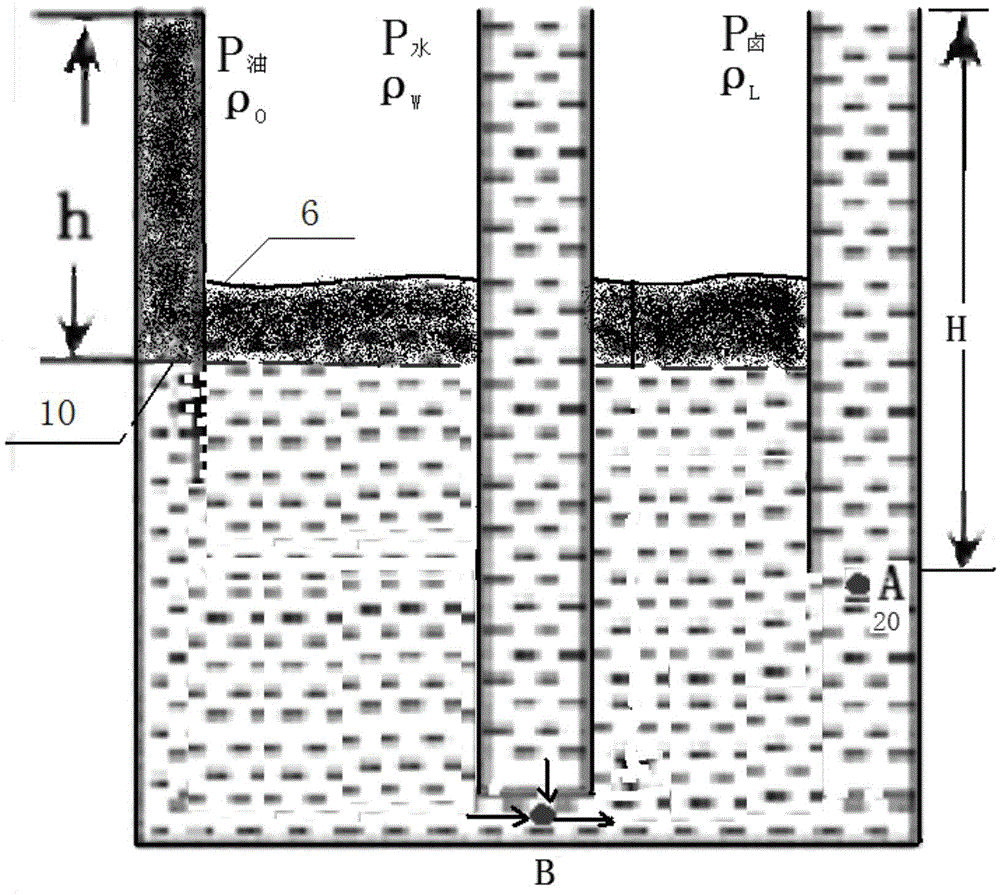

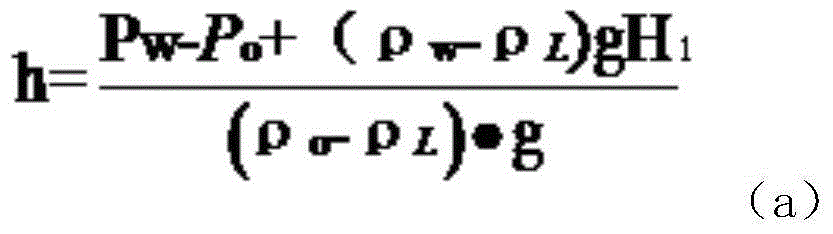

[0044] Step 1. First, install a high-precision pressure gauge and a density gauge 5 at the gate of the oil injection pipe 1 of the wellhead device (such as figure 1 shown), used to test the wellhead pressure P of the oil injection pipe O and density value ρ O , respectively install a high-precision pressure gauge and a density gauge 4 at the gate of the brine extraction pipe 2 to test the wellhead pressure P of the brine extraction pipe L and density value

[0045] ρ L ;

[0046] Step 2. Turn off the water injection pump, and at the same time close the gates of oil injection pipe 1, brine extraction pipe 2 and water injection pipe 3, and let it stand for 30 minutes to stabilize the liquid press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com