Building control method of lining of tubular kiln

A kiln lining and control method technology, applied in the direction of lining repair, etc., can solve the problems of inconvenient control method for the kiln lining of the cylinder, increase the difficulty of construction control, affect the expansion joint of the annular air duct, etc., and achieve the design of the production steps Reasonable, improve labor efficiency and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Control method of dry quenching coke oven inner lining masonry

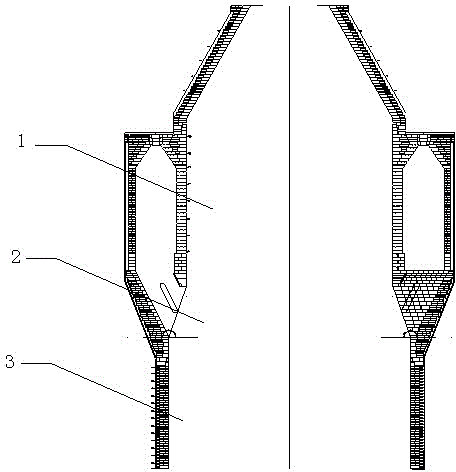

[0038] see now figure 1 , figure 1 It is a structural schematic diagram of each section of the CDQ coke oven lining in the embodiment of the present invention. As shown in the figure, the cylindrical kiln of the CDQ oven is divided into an annular air duct section 1, a chute section 2 and a cooling section 3 from top to bottom, and the annular air duct section, the chute section and the cooling section From the furnace shell to the center of the furnace, the refractory structure is divided into 4 cushion layers of ceramic fiber felt and 5 heat insulating layers of heat insulating bricks. The masonry of refractory fiber blanket and heat insulating layer is carried out by conventional control methods.

[0039]

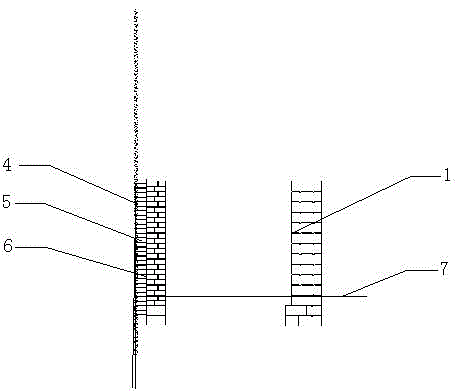

[0040] see now figure 1 , figure 1 is a front view of the lifting device of the embodiment, figure 2 It is a side view of the lifting device of the embodiment of the present invention. As sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com