Pulverized coal burner and boiler

A technology for pulverized coal burners and air ducts, which is applied in the direction of burners, burners for burning powder fuel, and combustion methods, etc. It can solve the problems of inability to effectively suppress NOx, poor concentration separation effect of pulverized coal airflow, and chaotic airflow field, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

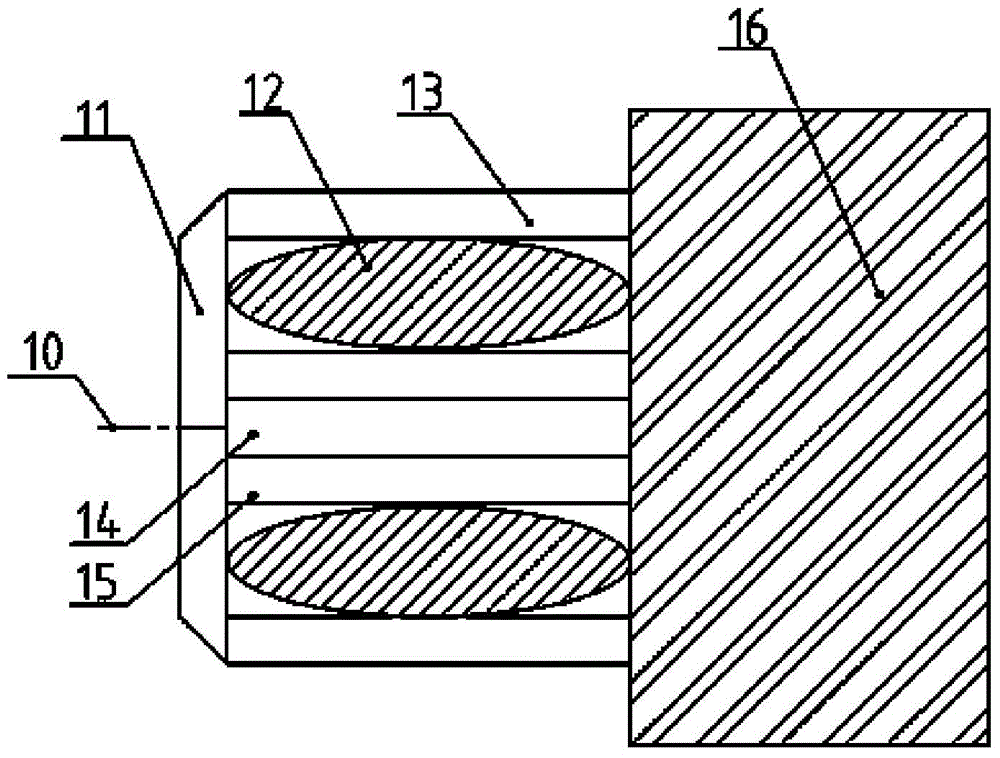

[0067] like Figure 4 and Figure 5 As shown, the pulverized coal burner provided by the embodiment of the present invention includes a central air duct 56, a primary air duct 52, a secondary air duct ( Image 6 Shown is the inner secondary air cylinder) 53 and the dual-zone flow field generating structure arranged in the primary air cylinder 52 (the preferred embodiment of this structure will be described in detail below), wherein:

[0068] The secondary air cylinder 53 is sheathed outside the primary air cylinder 52 .

[0069] The primary air duct 52 is sleeved outside the central air duct 56 .

[0070]The double-zone flow field generation structure can make the pulverized coal concentration of the pulverized airflow sprayed out by the primary air duct 52 through the dual-zone flow field generation structure be distributed in a state of being thick on the outside and light on the inside. Form the first annular recirculation zone 72 between 75 and the powder-containing air...

Embodiment approach 2

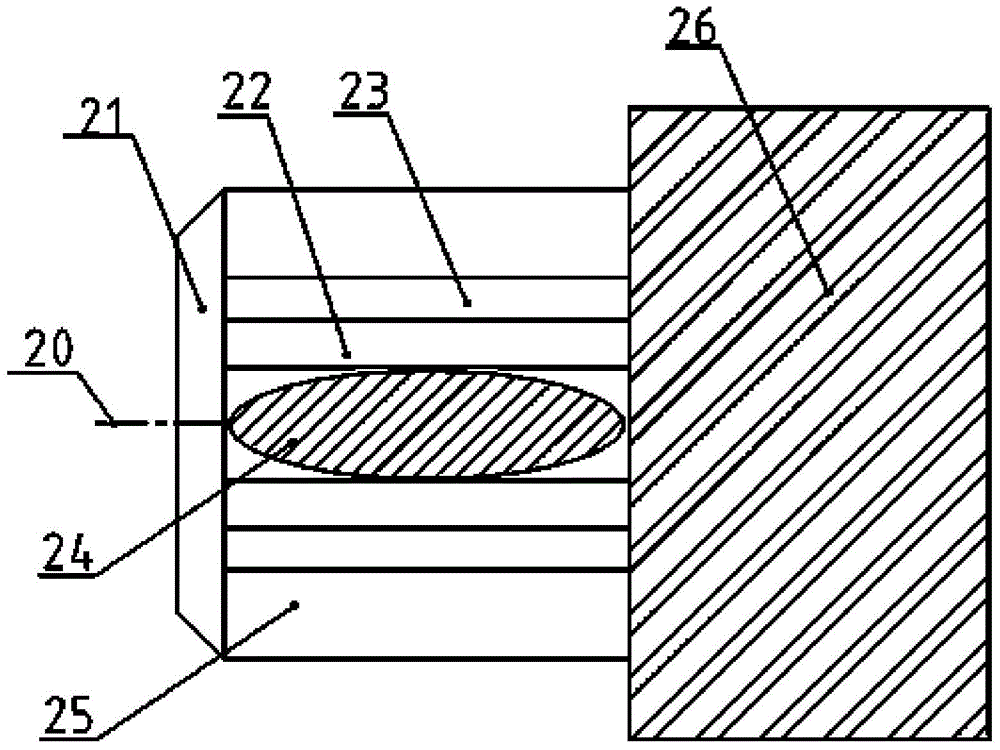

[0104] like Figure 6 ~ Figure 7 As shown, the pulverized coal burner provided in Embodiment 2 of this paper includes a central air duct 46, a primary air duct 42, a guide air duct 425, a block 421, and a guide device 424 that can adjust the rigidity or momentum of the pulverized coal airflow , the pulverized coal burner also includes a nozzle section 426, wherein:

[0105] The primary air duct 42 is sheathed outside the central air duct 46 .

[0106] The guide air cylinder 425 is located between the downstream section of the central air cylinder 46 and the downstream section of the primary air cylinder 42 .

[0107] The block 421 is fixed on the inner wall of the upstream section of the primary air cylinder 42, the flow guide device 424 is fixed on the outer wall of the central air cylinder 46, and the flow guide device 424 is located in the flow guide air cylinder 425, and the flow guide air cylinder 425 A nozzle section 426 is provided at the outflow port of the nozzle, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com