Mobile guide rail mechanism of sapphire wafer cleaner

A technology of sapphire wafers and moving guide rails, applied in mechanical equipment, linear motion bearings, cleaning methods and utensils, etc., can solve problems such as easy failure and poor load-bearing performance of sliders, reduce the probability of failure, and have strong load-bearing capacity. , the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

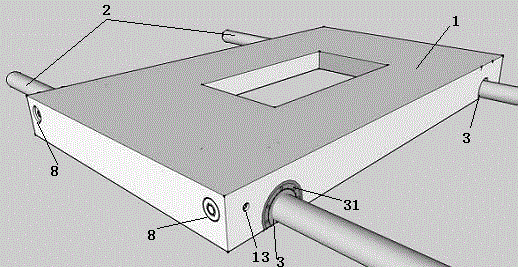

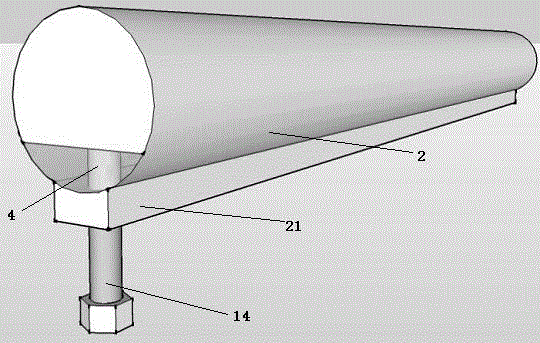

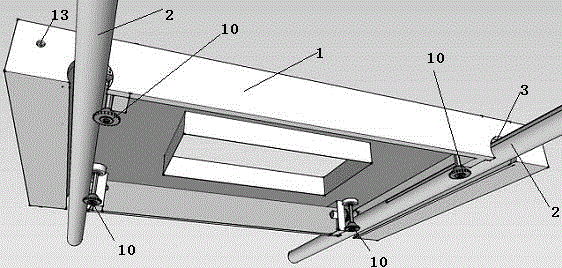

[0024] As shown in the figure, a moving rail mechanism for a sapphire wafer cleaning machine includes a supporting moving seat 1 and two optical axis guiding rails 2, and is characterized in that two rail mounting holes 3 are respectively provided on both sides of the supporting moving seat 1, The mounting holes 3 are arranged symmetrically, and the optical axis guide rail 2 runs through the supporting moving base 1 through the mounting hole 3, and the two optical axis guiding rails 2 are distributed in parallel at both ends of the supporting moving base 1; the optical axis guiding rail 2 The bottom is provided with several threaded holes 4, and the bottom of the optical axis guide rail 2 is provided with a guide rail pad 21, and the optical axis guide rail 2 is installed on the fuselage of the cleaning machine through the threaded holes 4 and screw rod 14; There are four h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com