Gear and rack cylinder with spring buffering function

A technology of spring buffering and gear teeth, which is applied in the field of cylinder buffering, can solve problems such as poor sealing effect and wear, and achieve the effect of compact buffering structure and protection of the guide piston

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

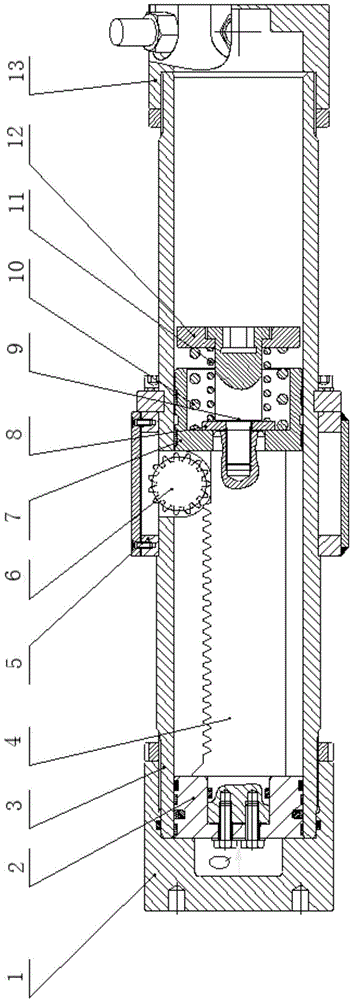

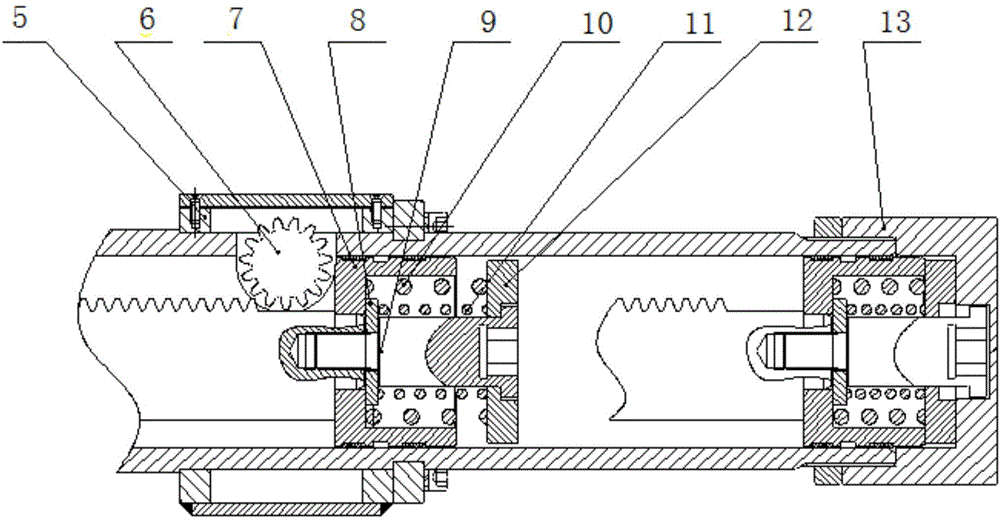

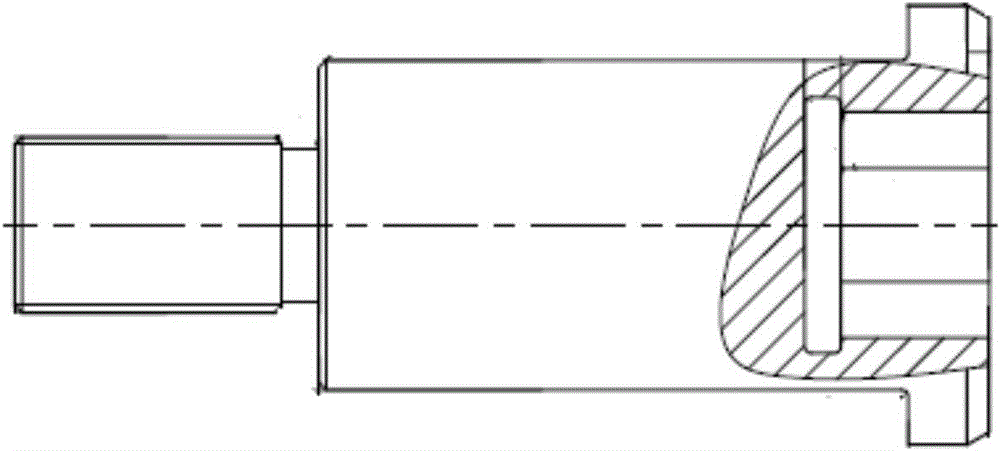

[0020] as attached figure 1 and 2 As shown, the present invention provides a rack-and-pinion cylinder with spring cushioning, including an end cover 1, a piston 2, a cylinder barrel 3, a rack 4, a box body 5, a gear box 6, a guide piston 7, a baffle plate 8, Bolt 9, large spring 10, small spring 11, pad 12 and cylinder bottom 13;

[0021] Wherein, the cylinder 3 is a cylindrical cylinder with both ends open, threaded sections are processed on the outer peripheral surface of the two ends of the cylinder, and an axial limit boss and a keyway are arranged on the outer peripheral surface of the middle section of the cylinder. The distance between the limiting boss and the keyway is the width of the gear box 6;

[0022] The end cover 1 and the cylinder bottom 13 are processed with internal threads that match the threaded sections at both ends of the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com