Rapid in-place device and rapid in-place method for prefabricated wallboard of prefabricated building

A technology of prefabricated wall panels and prefabricated assembly, which is applied in construction, building structure, and processing of building materials, etc. It can solve the problems of workers working at heights, unable to achieve one-time positioning, and low positioning accuracy, so as to improve employment The effects of improving positioning efficiency and positioning accuracy, improving positioning efficiency and positioning accuracy, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

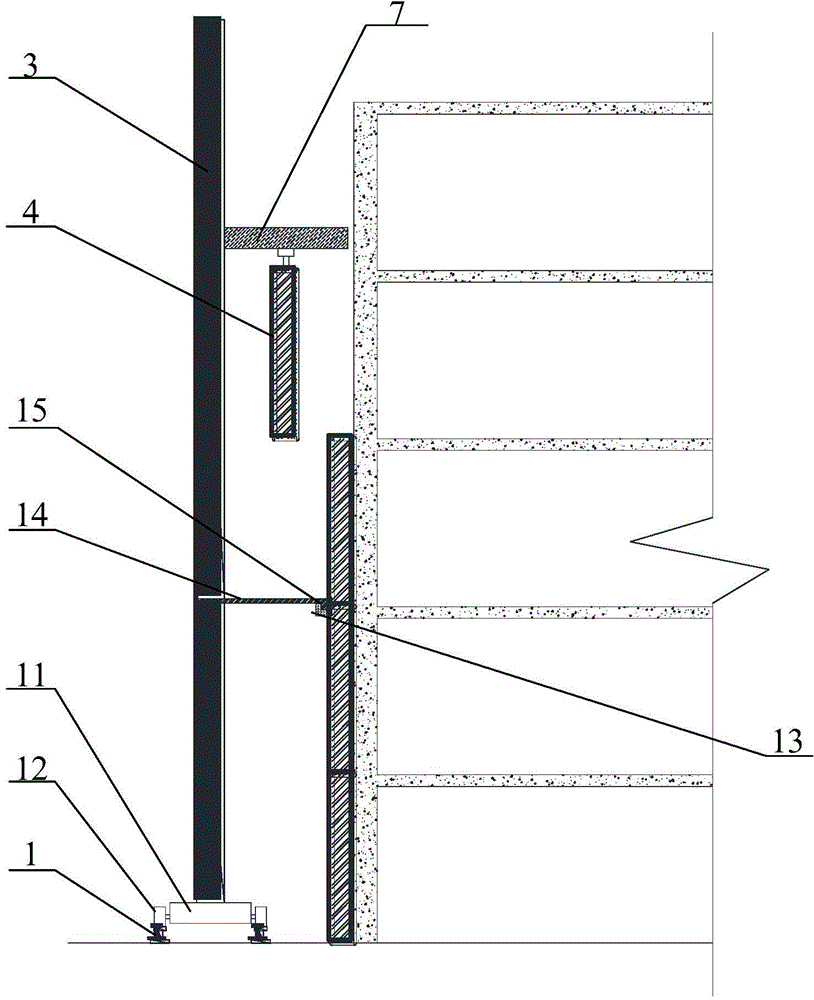

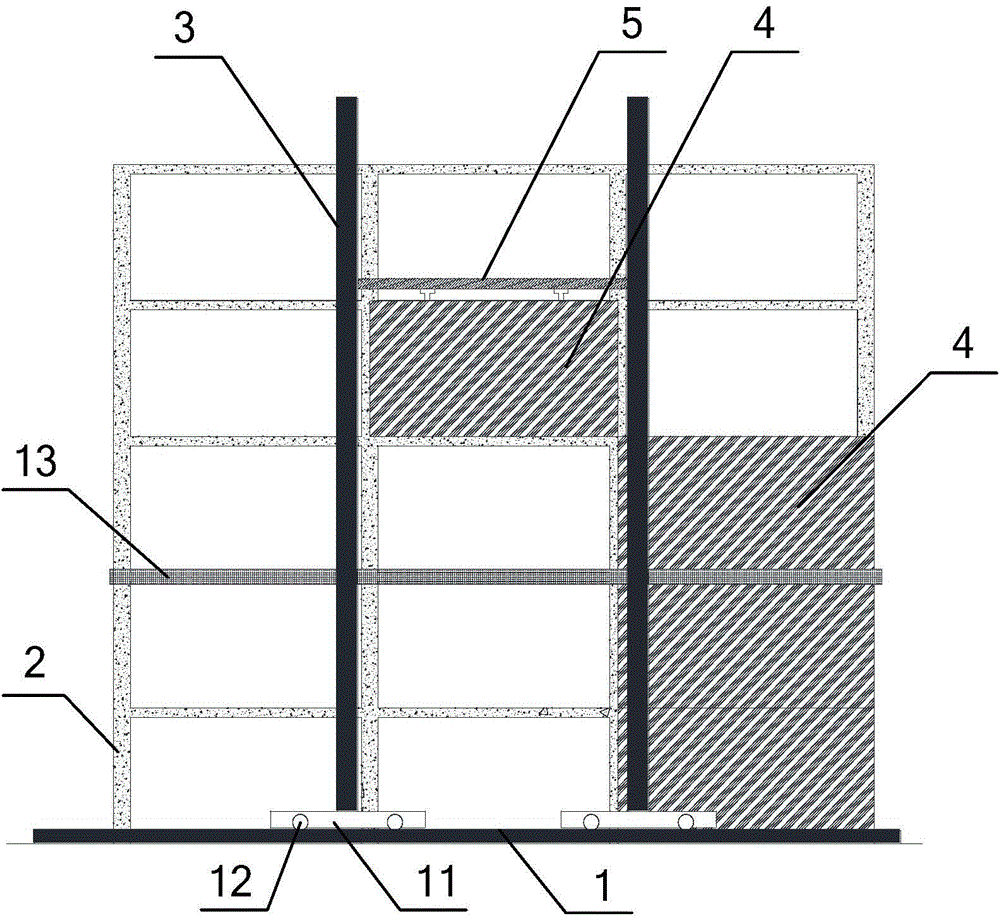

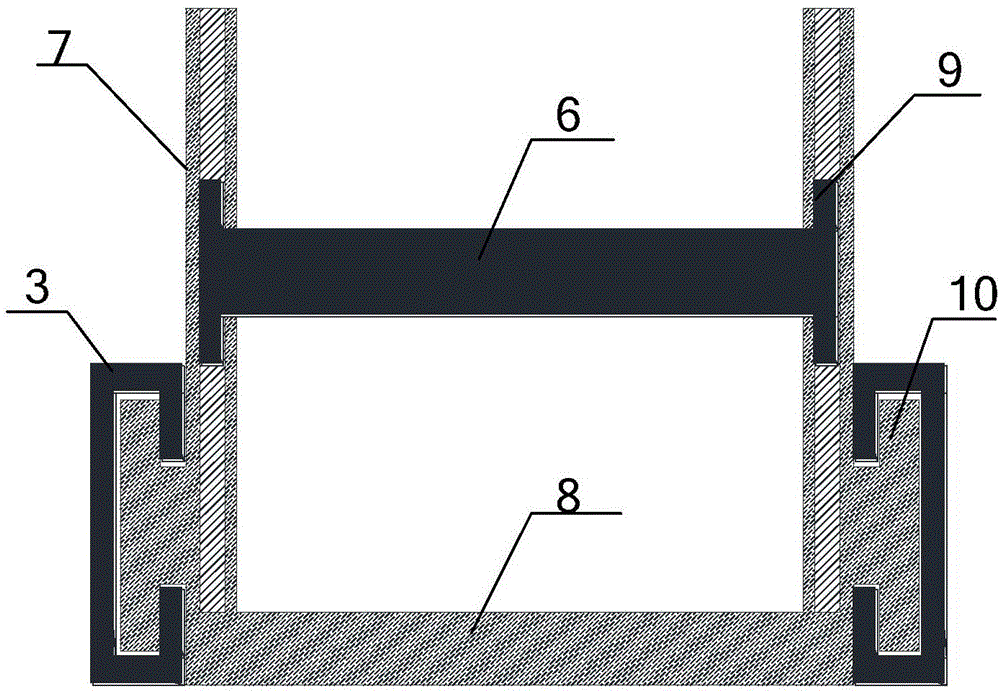

[0045] read on Figure 1 to Figure 3 , this embodiment discloses a method for quickly placing prefabricated wall panels in a prefabricated building, including the following steps:

[0046] In the first step, the prefabricated prefabricated building prefabricated wall panel quick positioning device as described in embodiment 1 is installed on one side of the building frame 2;

[0047] In the second step, the prefabricated wall panel 4 to be installed is suspended below the horizontal push guide rail crossbeam 6;

[0048] The third step is to move the pair of vertical guide rails 3 along the ground track 1, and move the horizontal pushing guide rail mechanism 5 along the pair of vertical guide rails 3, so that the prefabricated wall panels 4 face the building A position for installing the prefabricated wall panel 4 on the frame 2;

[0049] The fourth step is to make the horizontal push track beam 6 move towards the direction close to the building frame 2 relative to the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com