Auxiliary feeding device for sewing machine

An auxiliary feeding and sewing machine technology, applied in sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problem of affecting the real-time effectiveness of the auxiliary feeding drive wheel feeding, unable to set to ensure the lubrication of the one-way clutch moving parts, and the use of the auxiliary feeding drive wheel. Short life and other problems, to achieve the effects of wide applicability, synchronous and stable feeding, and good gripping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

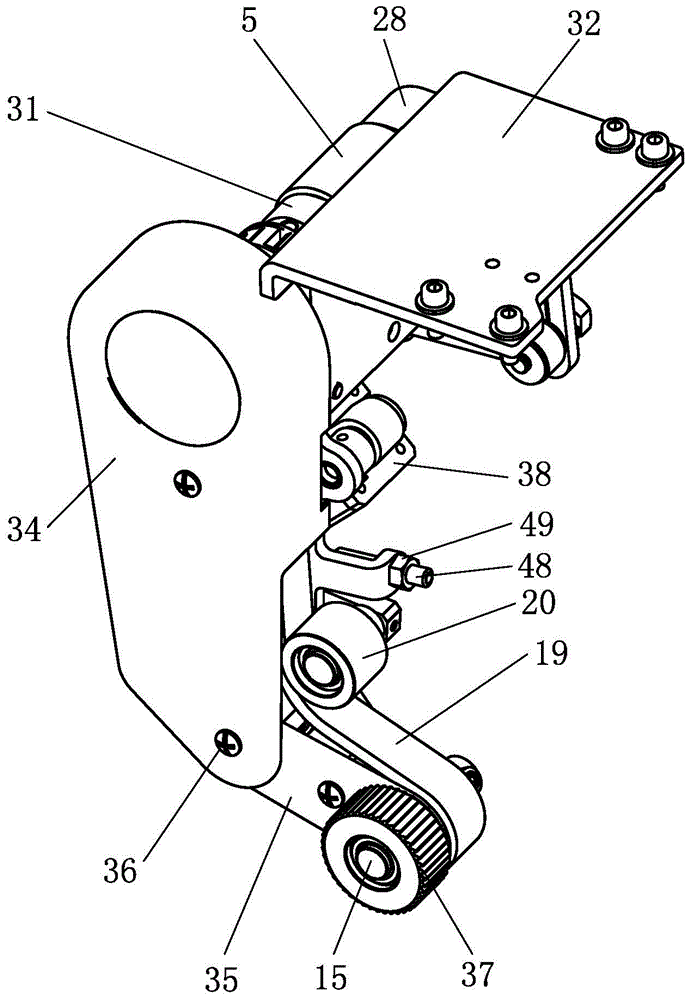

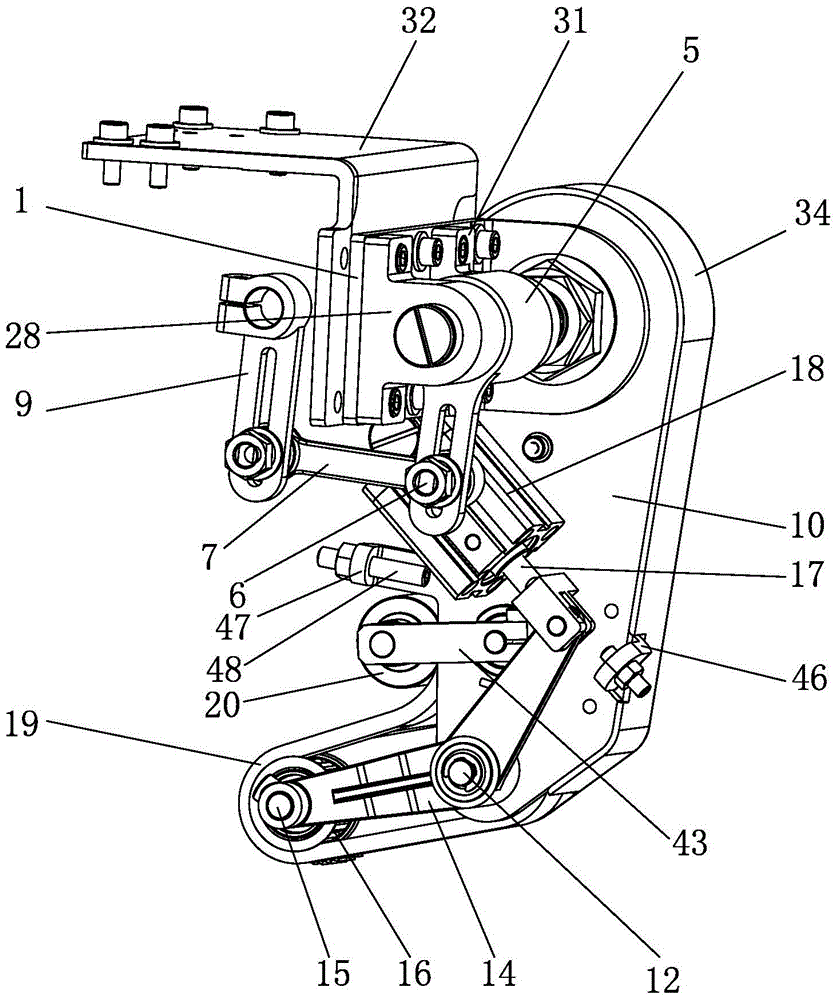

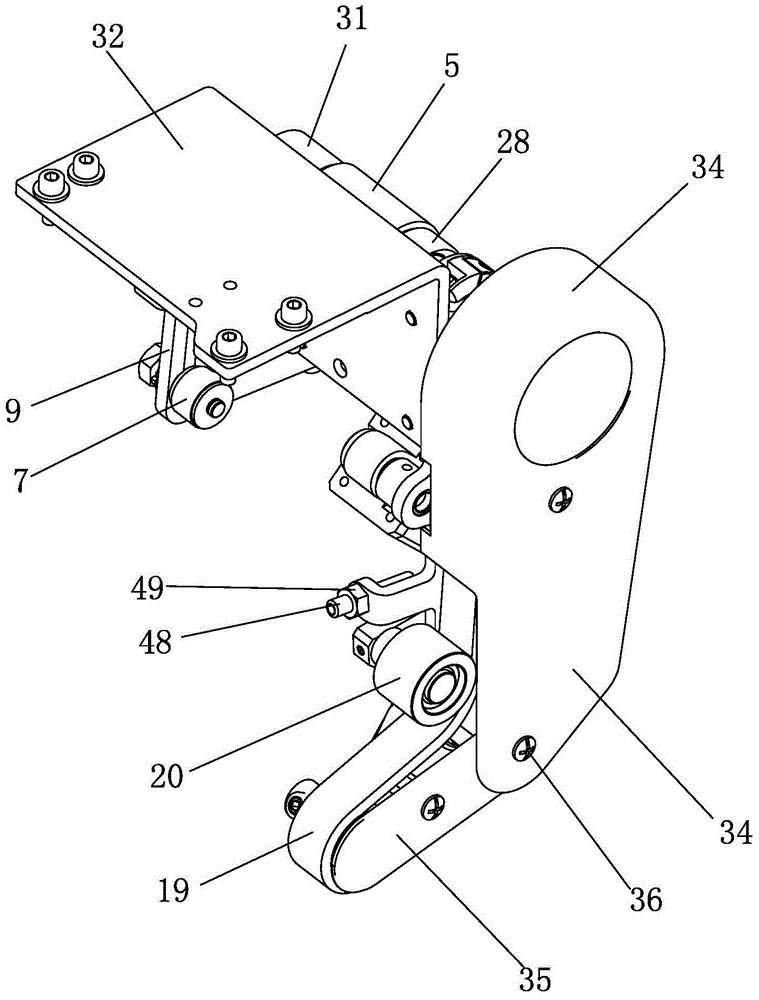

[0044] The present invention will be further described below with specific embodiment, see figure 1 -15:

[0045] An auxiliary feeding device for a sewing machine, comprising a one-way clutch drive assembly and a tug wheel assembly, the one-way clutch drive assembly is: including a one-way clutch drive star wheel shaft 2 coaxially installed on the tug wheel mounting bracket 1 and a large synchronous Axle pin 3, one-way clutch driving star wheel shaft 2 and large synchronous wheel shaft pin 3 are connected through coupling 4, one-way clutch driving star wheel shaft 2 and large synchronous wheel shaft pin 3 rotate in one direction, outside the one-way clutch driving star wheel shaft 2 The drive swing rod 5 is sleeved, and the other end of the drive swing rod 5 is connected to one end of the connecting rod 7 through the pivot pin 6, and the other end of the connecting rod 7 is provided with an adjustment connecting rod 9 for connecting with the swing shaft 8. The shaft coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com