Nitrocotton for flame-retardant celluloid and preparation method of nitrocotton product

A technology of nitrocellulose and celluloid, which is applied in the field of preparation of chemical plastic preparation products, and can solve the problems of small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

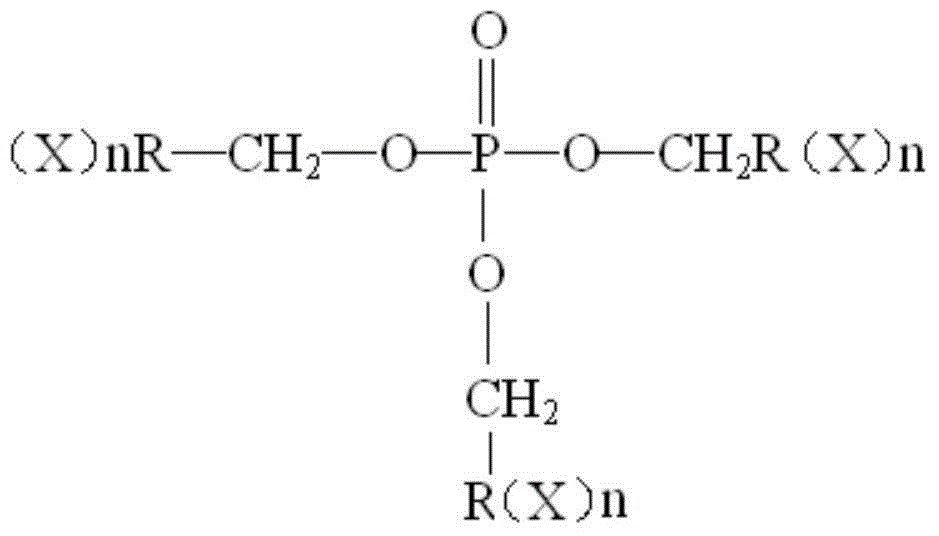

Image

Examples

Embodiment 1

[0020] Put 2.6g of trichloroethyl phosphate into a container, add 14ml of acetone, stir to dissolve the trichloroethyl phosphate evenly, then add 9g of celluloid-grade nitrocellulose, knead manually to make it fully plasticized, and dry in the air After that, nitrocellulose for flame retardant celluloid was obtained. After 12 hours, use a match to ignite the nitrocellulose, which is difficult to ignite. Even if it is lit, once the fire source leaves, the flame on the nitrocellulose will go out very quickly.

Embodiment 2

[0022] Get 35g of trichloropropyl phosphate and put it into the container, add 100g of acetone, stir to dilute and dissolve the trichloropropyl phosphate, then add the molten material to the kneader, then add 90g of nitrocellulose, start the kneader, After plasticizing for 30 minutes, nitrocellulose for flame retardant celluloid was obtained; after taking out the nitrocellulose, a calender was used to make a flame retardant celluloid plate with a thickness of about 2 mm. After the board is dried for 24 hours, it is difficult to ignite it with fire. Even if it is lit, once the fire source leaves, the flame on the board can be extinguished quickly.

Embodiment 3

[0024] Add 35g of tris(tribromoneopentyl) phosphate to the jacketed kneader, add 110g of cyclohexanone, heat to 48-55°C and stir to fully dissolve the phosphate ester, then process at a temperature not lower than 48°C Next, add 90g of nitrocellulose, continue stirring and kneading, and plasticize for about 30 minutes to obtain nitrocellulose for flame retardant celluloid. After discharging, filter and calender to make a flame retardant celluloid sheet. After the board is dried for 24 hours, it is difficult to light it with fire. Even if it is lit, once the fire source leaves, the flame on the board can be extinguished quickly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com