A kind of fluorosilicone resin, preparation method and application thereof

A fluorosilicone resin and reactor technology, applied in the field of building materials production, can solve the problems of high price, uneven protection effect, etc., and achieve the effects of easy availability of raw materials, simple and feasible production operation, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

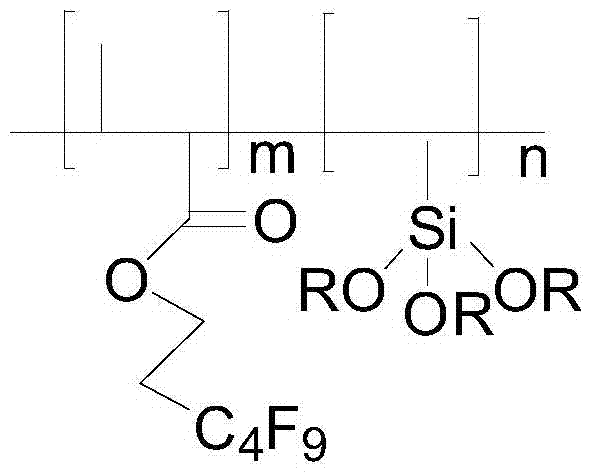

Image

Examples

Embodiment 1

[0018] Synthesis of embodiment 1 perfluorobutyl triethoxy fluorosilicone resin

[0019]

[0020] (1) 100g vinyltriethoxysiloxane is added by weight in the reactor, add 2g of dibenzoyl peroxide and 3g of methyl ethyl ketone peroxide, stir well, and the solution is stirred at room temperature for 1 hour, Prepolymer A is obtained.

[0021] (2) 100g 2-(perfluorobutyl) ethyl methacrylate is added to the reactor by weight, 3g of azobisisobutyronitrile and 1g of tert-dodecyl mercaptan are added, stirred evenly, and The solution was stirred at room temperature for 1 hour to obtain prepolymer B.

[0022] (3) Add the above-mentioned prepolymers A100g and B10g into the reactor, add 2g of cobalt naphthenate, 3g of mercaptoethanol and 5g of 3-aminopropyltriethoxysilane coupling agent, stir well, and dissolve the solution Stir at room temperature for 3 hours to obtain perfluorobutyltriethoxyfluorosilicone resin.

[0023] The resin test results are as follows:

[0024] Molecular weigh...

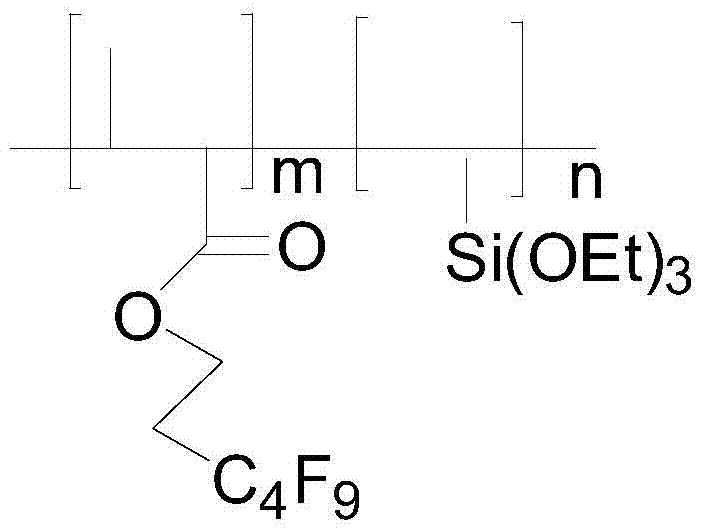

Embodiment 2

[0027] Embodiment 2: the synthesis of perfluorobutyltrimethoxy fluorosilicone resin

[0028]

[0029] (1) 100g of vinyltrimethoxysiloxane is added by weight into the reactor, 5g of dibenzoyl peroxide and 1g of methyl ethyl ketone peroxide are added, stirred evenly, and the solution is stirred at room temperature for 0.5 hour to obtain Prepolymer A.

[0030] (2) 100g 2-(perfluorobutyl) ethyl methacrylate is added to the reactor by weight, azobisisobutyronitrile and 3g tert-dodecyl mercaptan are added, stirred evenly, and The solution was stirred at room temperature for 1 hour to obtain prepolymer B.

[0031] (3) Add the above-mentioned prepolymers A100g and B50g into the reactor, add 5g of cobalt naphthenate, 1g of mercaptoethanol and 10g of 3-(methacryloyloxy)propyltrimethoxysilane coupling agent, Stir evenly, and stir the solution at room temperature for 5 hours to obtain perfluorobutyltrimethoxyfluorosilicone resin.

[0032] The resin test results are as follows:

[0...

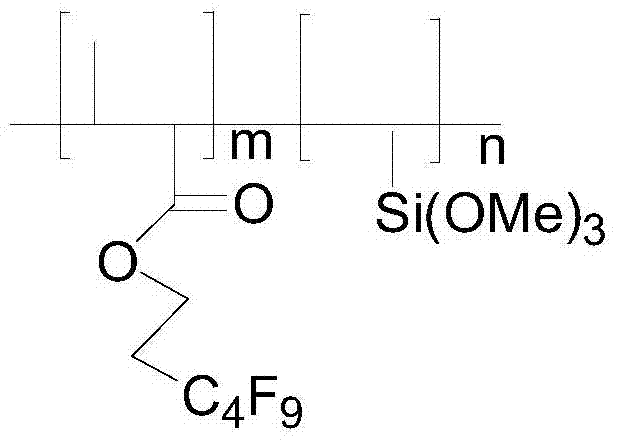

Embodiment 3

[0036] Embodiment 3: the synthesis of perfluorobutyl tripropropoxy fluorosilicone resin

[0037]

[0038] (1) 100g vinyltripropoxysiloxane is added by weight in the reactor, add 1g of dibenzoyl peroxide and 5g methyl ethyl ketone peroxide, stir well, and the solution is stirred at room temperature for 2 hours, Prepolymer A is obtained.

[0039] (2) 100g 2-(perfluorobutyl) ethyl methacrylate is added by weight into the reactor, 5g of azobisisobutyronitrile and 1g of tert-dodecyl mercaptan are added, stirred evenly, and The solution was stirred at room temperature for 1 hour to obtain prepolymer B.

[0040] (3) Add the above-mentioned prepolymers A100g and B30g into the reactor, add 3g of cobalt naphthenate, 5g of mercaptoethanol and 1g of 3-glycidyl etheroxypropyl trimethoxysilane coupling agent, stir evenly, The solution was stirred at room temperature for 2 hours to obtain perfluorobutyl tripropropoxyfluorosilicone resin.

[0041] The resin test results are as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com