Ball follow-shaped yttrium oxide self-assembly thin film and preparation method thereof

A yttrium oxide, self-assembly technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of unsuitability for large-scale production, high equipment requirements, limited use of yttrium oxide thin film structure, etc. Hydrothermal deposition, wide range of applications, effects suitable for large-scale synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] According to the preparation method of a spherical flower-shaped yttrium oxide self-assembled film provided by the present invention, the preparation method may include the following steps: (1) soaking the substrate impregnated with absolute ethanol in zinc nitrate and hexamethylene tetramine The first hydrothermal reaction is carried out in the solution to form a zinc oxide nanorod array film on the substrate; (2) The substrate obtained in step (1) with the zinc oxide nanorod array film is soaked in the yttrium nitrate solution for the second Secondary hydrothermal reaction.

[0018] According to the present invention, first, a zinc oxide nanorod array thin film is prepared on the surface of a target substrate. Specifically, the cleaned substrate can be soaked with absolute ethanol to make the surface of the substrate bear alkaline groups. Among them, the soaking time in ethanol plays an important role in the density of ZnO nanorod array films. Long-time immersion can...

Embodiment 1

[0033] Preparation of zinc oxide nanorod array thin film: Soak the cleaned quartz glass substrate with absolute ethanol for 3 days, 15ml each of the quartz glass substrate and 0.1M zinc nitrate and 0.1M hexamethylenetetraammonium solutions according to the volume ratio of 1: 1. Put it into a 50ml stainless steel hydrothermal kettle, conduct the first hydrothermal reaction at a constant temperature of 95°C for 4 hours, then dry the powder, and rinse the quartz glass substrate with the zinc oxide nanorod array film and dry it.

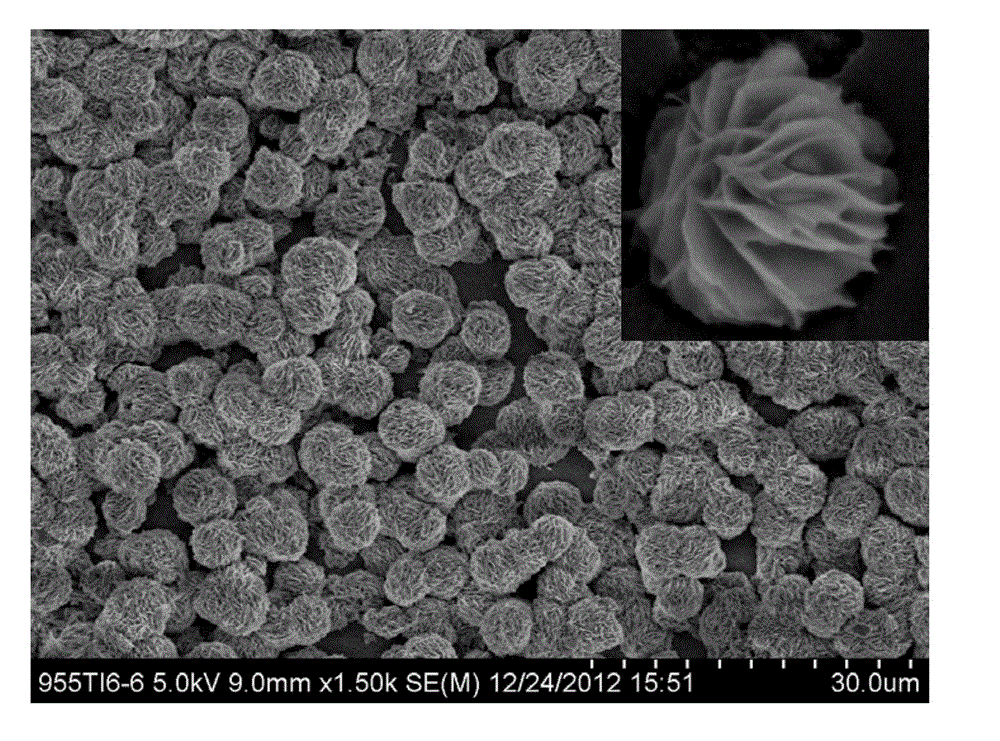

[0034] Put the quartz glass substrate with ZnO nanorod array thin film into 0.12M yttrium nitrate solution, and conduct the second hydrothermal reaction at 95°C for 2.5 hours to obtain a uniformly dispersed spherical flower-shaped self-assembled thin film of yttrium oxide ,Such as figure 1 As shown, the thickness of the spherical flower-shaped yttrium oxide self-assembled film is 5 microns.

Embodiment 2

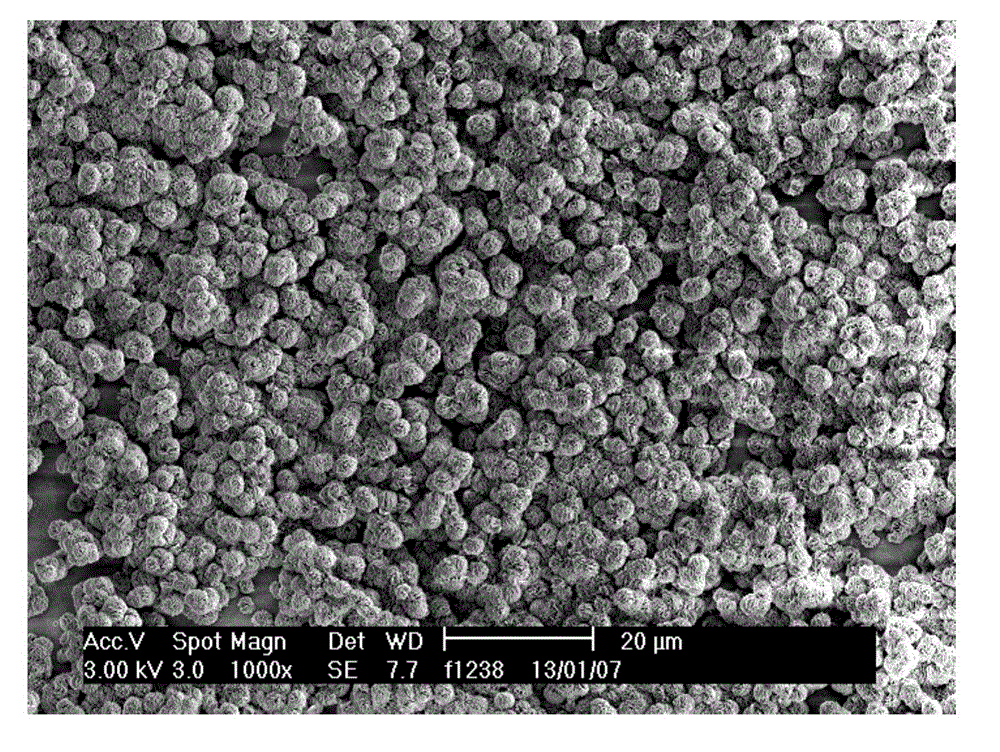

[0036]The preparation of the zinc oxide nanorod array film is the same as in Example 1, except that the quartz glass substrate with the zinc oxide nanorod array film is placed in a 0.2M yttrium nitrate solution, and the second time is carried out at a constant temperature of 90°C. After hydrothermal reaction for 2 hours, a uniformly dispersed spherical flower-shaped yttrium oxide self-assembled film was obtained, such as figure 2 As shown, the thickness of the spherical flower-shaped yttrium oxide self-assembled film is 5 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com