A wire rope brake

A technology of brakes and wire ropes, which is applied in the field of elevator safety brakes and automatic reset wire rope brakes. It can solve the problems of long control delay, limited operating space, and high reset, so as to reduce delay and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in detail

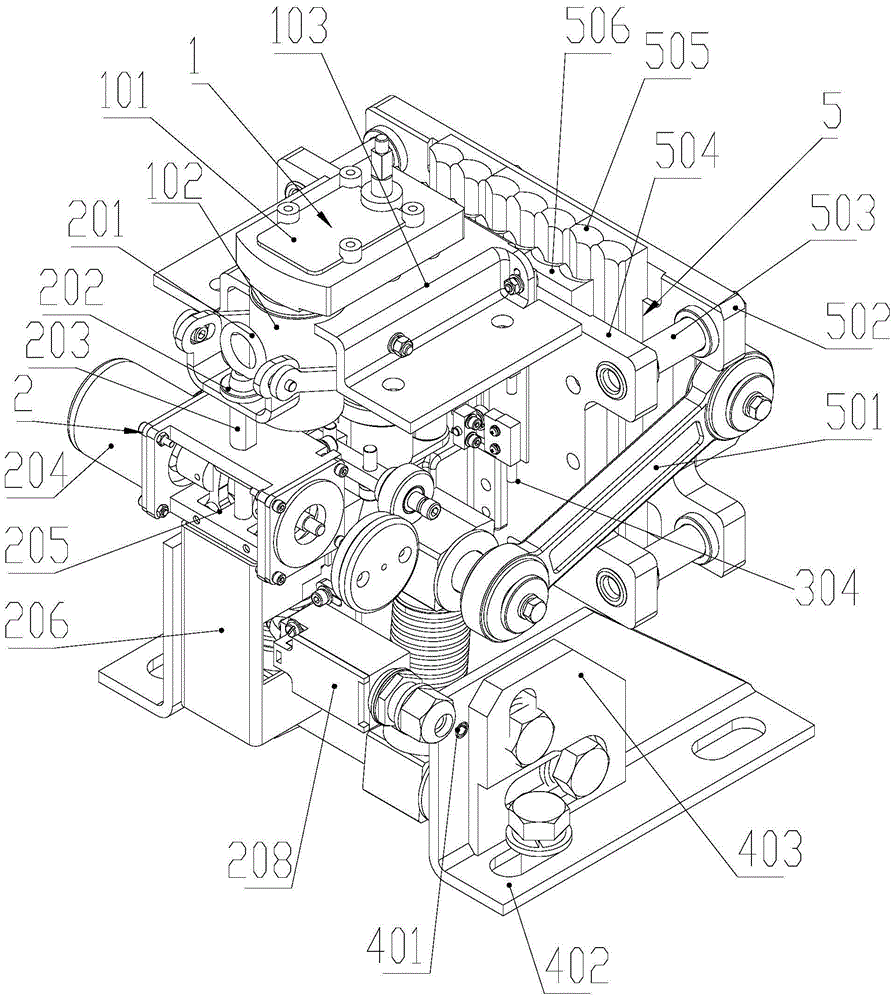

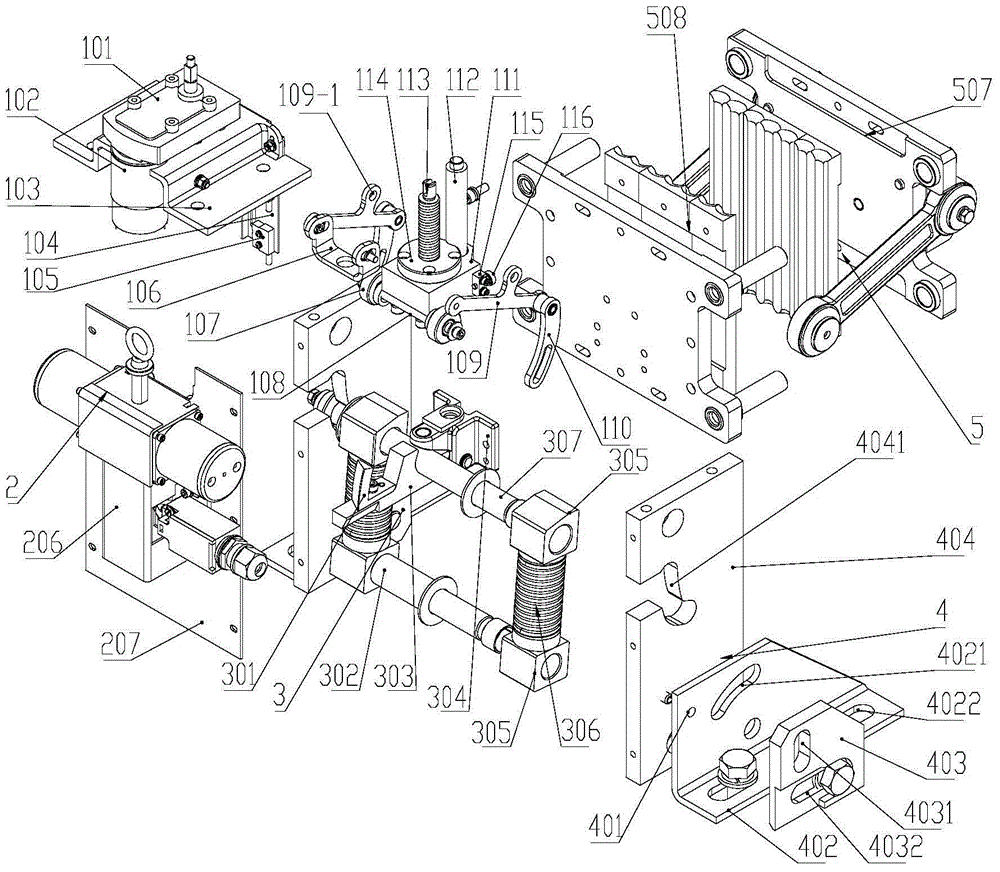

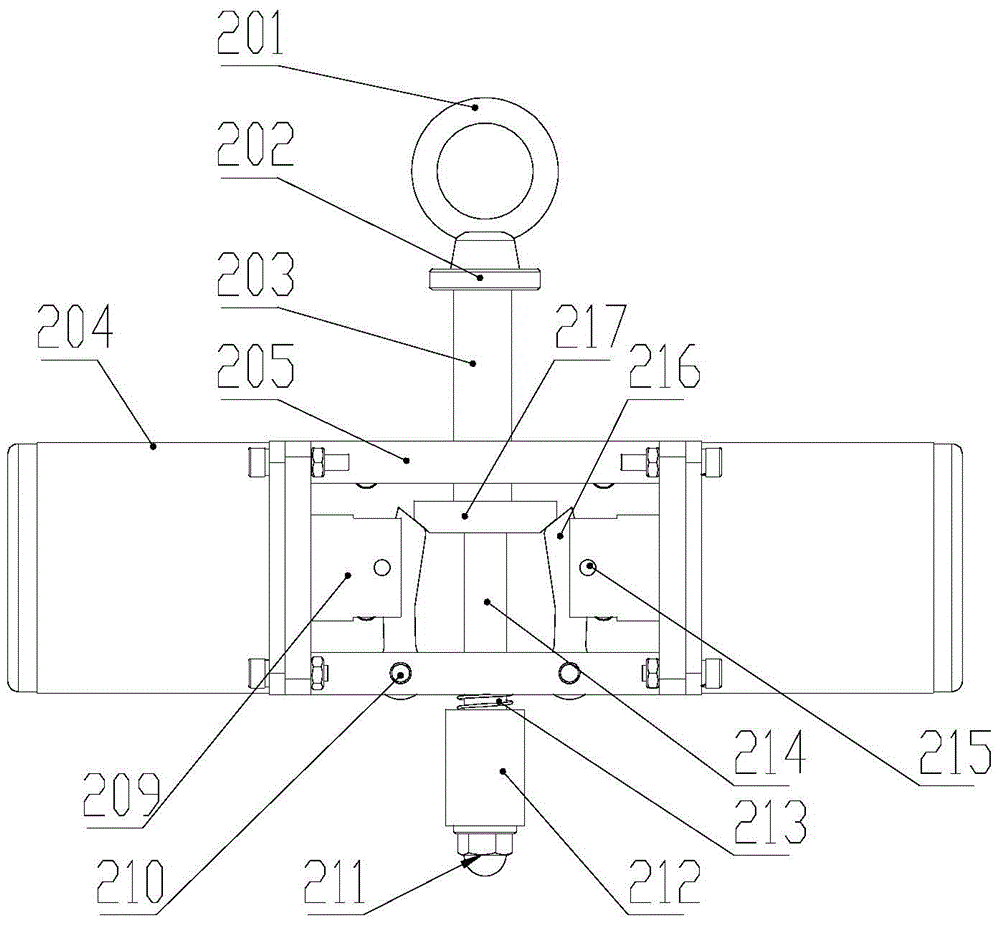

[0040] see Figure 1-4The wire rope brake in this embodiment includes an energy storage locking mechanism, a friction dynamic / fixed brake lining mechanism, a bracket mechanism, an impact trigger mechanism, and a motor screw reset mechanism. The energy storage locking mechanism and the brake lining mechanism are installed on the bracket mechanism. The impact trigger mechanism is installed on the rear side plate, and the reset mechanism is installed on the top plate. The specific structure is as follows:

[0041] The top plate 103 is installed on the upper part of the wire rope brake, the left and right side plates 404 are respectively installed on the support 402 on both sides of the wire rope brake, the support 402 is fixedly installed on the beam through the bottom mounting hole, and the rear side plate 207 is installed on the left and right sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com