Novel coiling type power transmission device

A power transmission device and winding technology, applied in the direction of transportation, packaging, conveyors, etc., can solve the problems of inability to realize two-way movement, complex structure, etc., and achieve simple and practical structure, low production and use costs, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

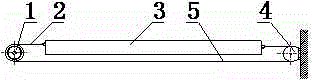

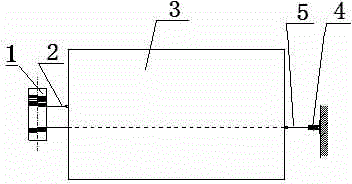

[0025] refer to figure 1 — figure 2 , the new winding type power transmission device of this embodiment, which includes a steel wire rope I2, a steel wire rope II5, a roller 1 and a reversing wheel 4, and the reversing wheel 4 is fixedly arranged at a position opposite to the roller 1, and the steel wire I2, One end of the wire rope II5 is wound on the roller 1, and the winding direction is opposite, the other free end of the wire rope I2 is directly connected to the loading platform 3, the wire rope II5 bypasses the reversing wheel 4, and then the other free end is connected to the loading platform 3.

Embodiment 2

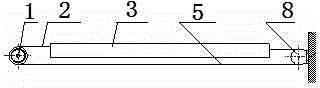

[0027] refer to image 3 — Figure 4 , the new winding type power transmission device of the present embodiment, which includes roller 1, reversing wheel I8, reversing wheel II9 and 2 groups of steel wire ropes: steel wire rope I2 and steel wire rope II5, steel wire rope III6 and steel wire rope IV7, said reversing wheel I8 , Reversing wheel II9 is fixedly arranged at the position opposite to roller 1, one end of the four steel wire ropes is wound on roller 1, and the winding direction of steel wire rope I2 and steel wire rope II5 is opposite, the winding direction of steel wire rope III6 and steel wire rope IV7 is opposite, and the wire rope The winding direction of Ⅰ2 and steel wire rope Ⅲ6 is the same, and the other free ends of steel wire rope Ⅰ2 and steel wire rope Ⅲ6 are directly connected to loading platform 3, and steel wire rope Ⅱ5 and steel wire rope Ⅳ7 are respectively bypassed by reversing wheel Ⅰ8 and Ⅱ9, and then the other free end is connected to Loading plat...

Embodiment 3

[0029] The new winding type power transmission device of this embodiment includes a pulley, a belt I, a belt II, and a reversing pulley, and the reversing pulley is fixedly arranged at a position opposite to the pulley. One end is wound on the pulley, and the winding direction is opposite. The other free end of the belt I is directly connected to the loading platform, and the belt II bypasses the reversing pulley, and then the other free end is connected to the loading platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com