Electric heating device for rail vehicle and rail vehicle

A rail vehicle and electric heating device technology, applied in the field of rail vehicles, can solve the problems that the side plate and bottom plate of the electric heater cannot be ventilated, affect the comfort of passengers, and the air convection effect is not good, so as to avoid excessive seat temperature, Good air convection effect, solve the effect of high heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

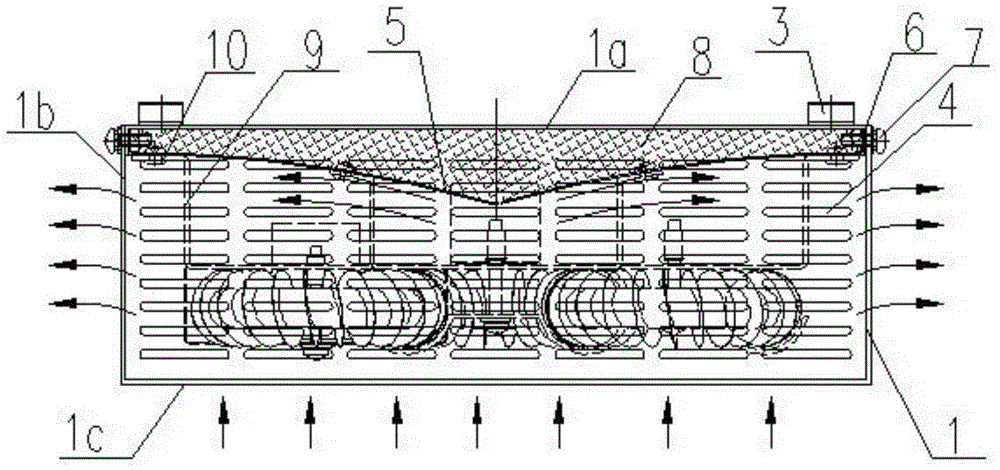

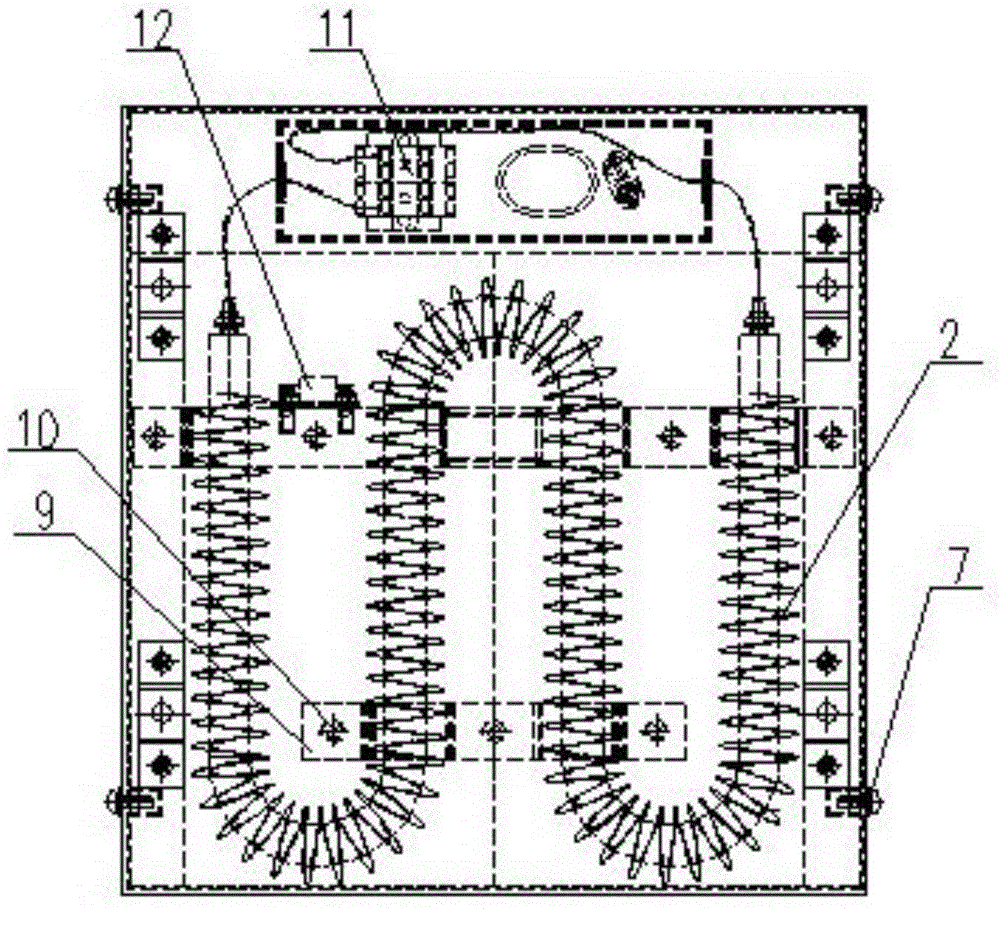

[0031] Such as figure 1 and figure 2 As shown, the electric heating device provided by the present invention includes a casing 1, and an electric heating element 2 is installed inside the casing 1. The casing 1 is composed of a top plate 1a, four side plates 1b and a bottom plate 1c. The top plate 1a, four side plates 1b and the bottom plate 1c can be fixedly connected together by screws, or the four side plates 1b and the bottom plate 1c can be integrally formed or welded together, and the top plate 1a can be fixedly connected with the side plate 1b separately to facilitate installation and maintenance.

[0032] On the upper surface of the top plate 1a of the cover shell 1, a plurality of mounting seats 3 are welded and installed, and the mounting seats 3 are fixedly connected with the seat frame (not shown in the figure) by bolts, and then the electric heating device is hung below the seat frame , the installation is very simple and convenient.

[0033] On the four side p...

Embodiment 2

[0044] The difference from Embodiment 1 is that the casing 1 does not have a top plate 1a, but the deflector 5 with flanges 6 around it and the top plate 1a of the casing 1 are separately integrated into a structural member with a cavity inside. The cavity is filled with heat insulating material 7, and then the entire structure filled with heat insulating material 7 is fixed on the side plate 1b of the casing 1 by bolts, so that during installation, repair and maintenance, the body of the casing 1 The top plate 1a, the deflector 5 and the heat insulating material 7 are disassembled and installed as a whole, which is convenient and quick.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com