Vehicle power transmission device

A technology for power transmission devices and vehicles, which is applied to power devices, air pressure power devices, transmission devices, etc., can solve problems such as uneven load distribution, and achieve the effect of uniform load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

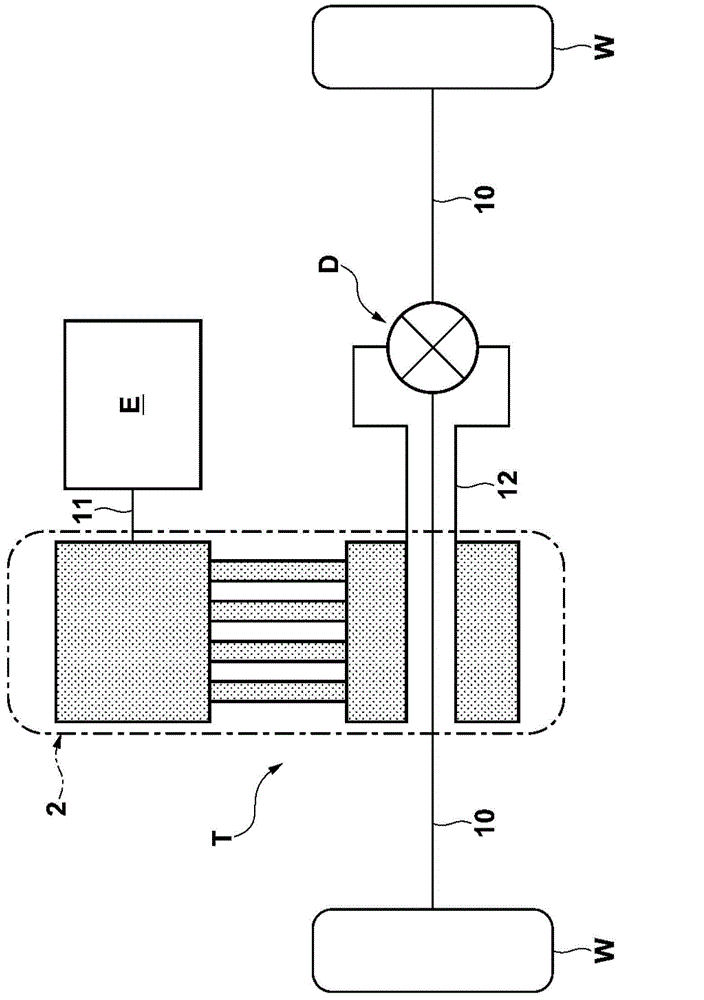

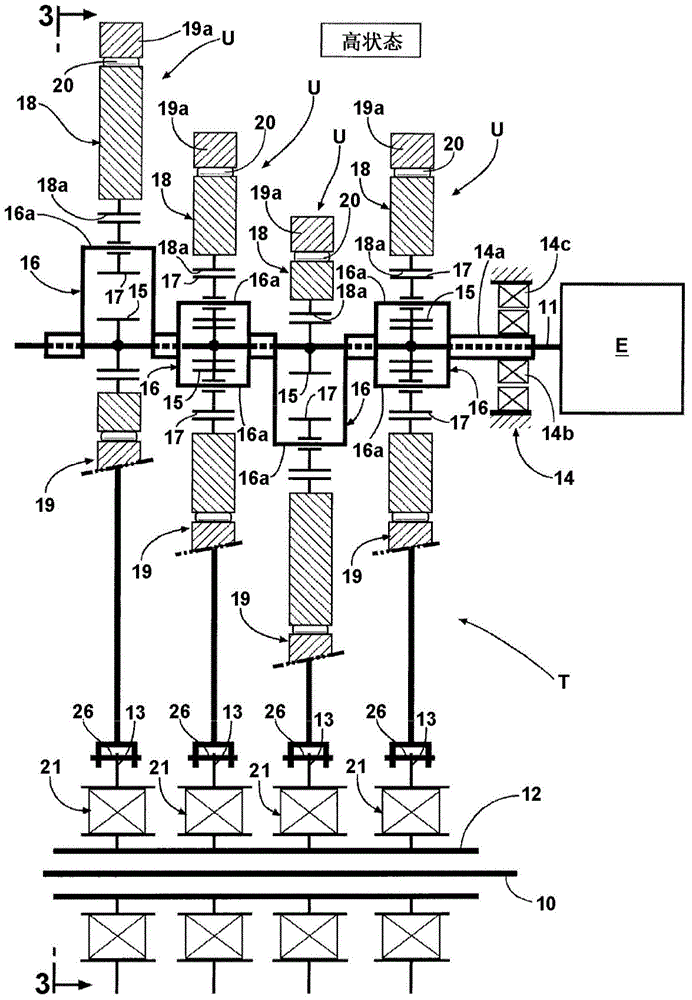

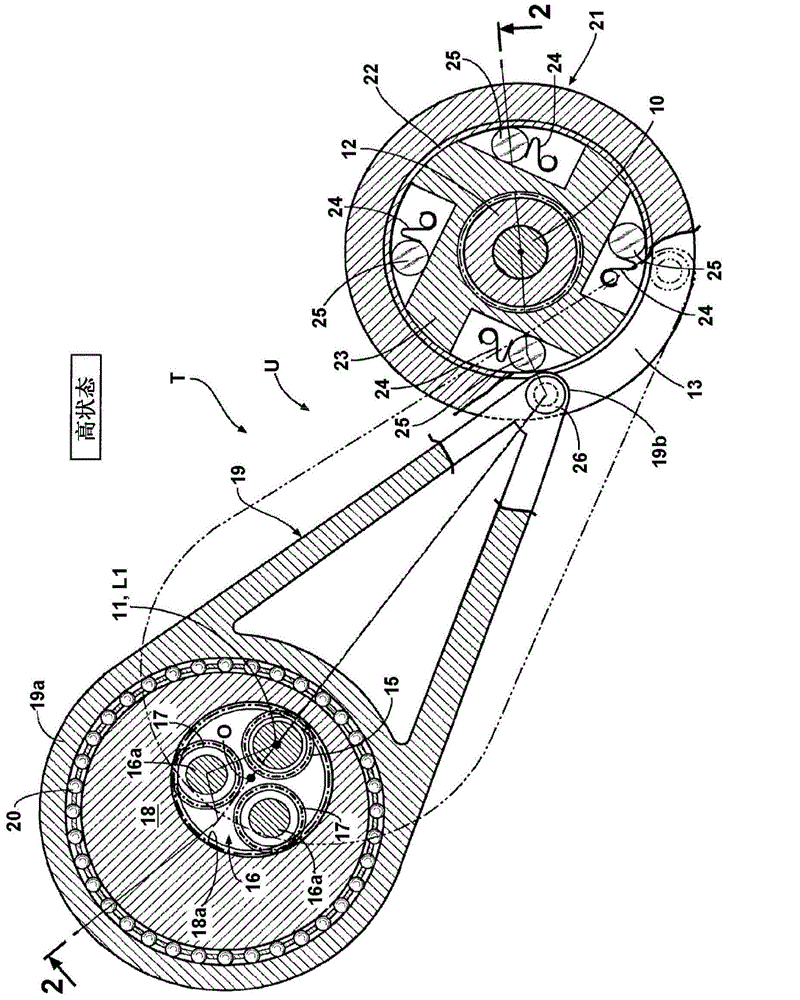

[0028] Below, based on Figure 1 to Figure 8 A-8C describes embodiments of the present invention. like figure 1 As shown, a power transmission device for a vehicle that transmits driving force of an engine E as a driving source to driving wheels W, W via left and right axle shafts 10 , 10 includes a crank-type continuously variable transmission T and a differential D.

[0029] Next, based on Figure 2 to Figure 6 A-6D The structure of the continuously variable transmission T is explained. like figure 2 and image 3 As shown, the continuously variable transmission T of this embodiment is formed by stacking a plurality of (four are shown in the embodiment) power transmission units U having the same structure in the axial direction, and these power transmission units U have A common input shaft 11 and a common output shaft 12 are arranged in parallel, and the rotation of the input shaft 11 is decelerated or accelerated and transmitted to the output shaft 12 .

[0030] Her...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com