Hydraulic steel-ball locking device for automobile chassis

A locking device, a technology for automobile chassis, applied in vehicle parts, transportation and packaging, elastic suspension, etc., can solve the problems of high cost and complex structure, and achieve the effect of simple overall structure, simple equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

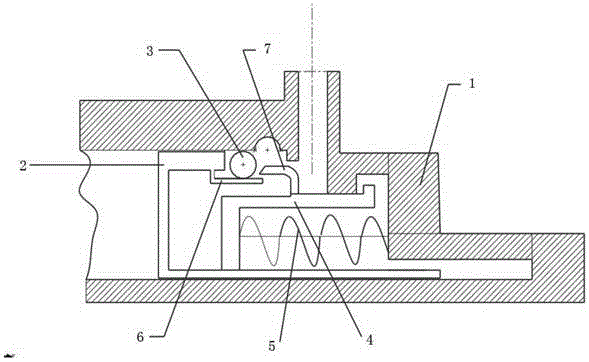

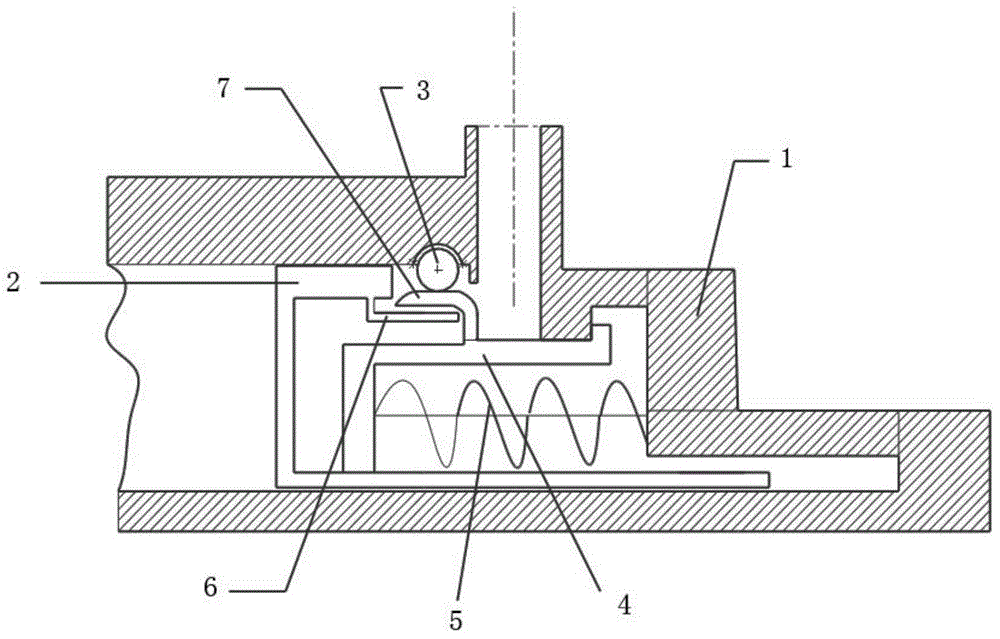

[0014] The reference signs in the description of the drawings are: piston cylinder 1, piston 2, steel ball 3, plunger 4, compression spring 5, ball setting block 6 and curved surface body 7.

[0015] Such as figure 1 As shown, a hydraulic steel ball locking device for automobile chassis in this embodiment includes a piston cylinder 1, a piston 2, a steel ball 3, a plunger 4 and a compression spring 5 with an oil injection hole, and the piston cylinder 1 There is a groove on the top, the shape of the groove matches the steel ball 3, and the shape of the piston 2 is "U". The short section is located on both sides of the piston sealing surface. The length of the long section of the piston is longer than that of the short section of the piston. The short section of the piston is provided with a ball block 6, and the shape of the plunger 4 is "L". The long section of the plunger is longer than the short section of the plunger, the short section of the plunger is slidably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com