Front mixing grinding material jet-flow continuous feeding system

A pre-mixed abrasive and feeding system technology, applied in the direction of abrasive feeding devices, abrasives, metal processing equipment, etc., can solve the problems of short working time, long charging time, and non-continuous feeding, so as to improve work efficiency And work quality, cutting efficiency improvement, the effect of price reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

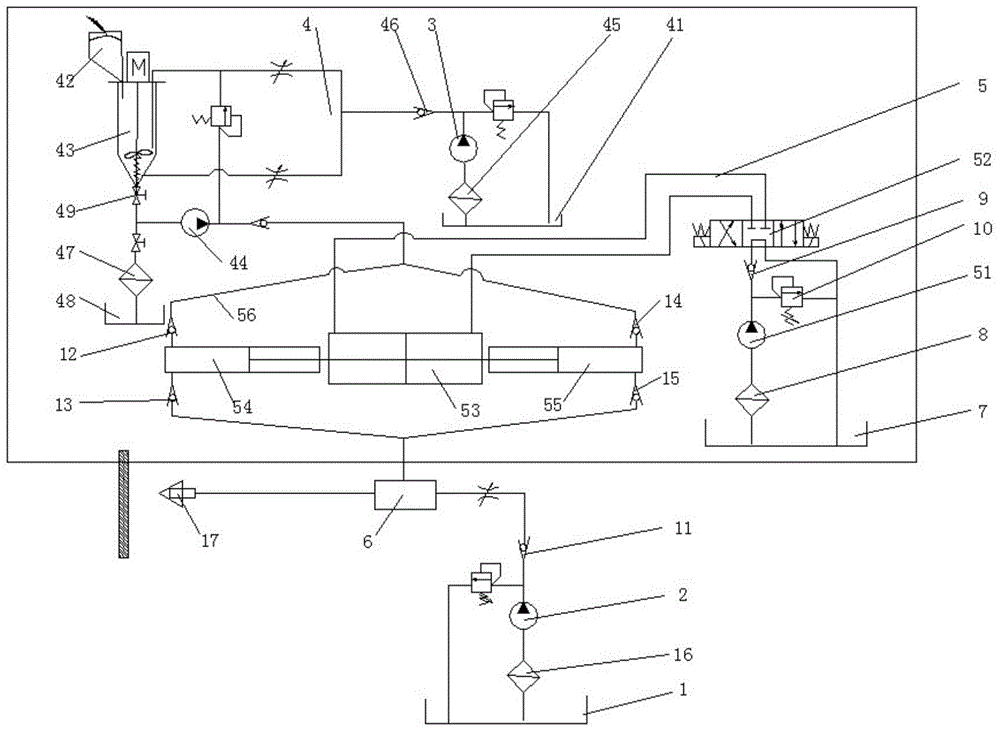

[0019] See figure 1 As shown, a pre-mixed abrasive jet continuous feeding system includes a main water tank 1, a high-pressure pump 2, a low-pressure pump 3, a continuous feeding system and a mixing chamber 6, one end of the main water tank 1 is communicated with the high-pressure pump 2, and the The output port of the high-pressure pump 2 is connected to the input port of the mixing chamber 6, and the input port of the low-pressure pump 3 is connected to the input port of the mixing chamber 6 through a continuous feeding system, which includes a feeding system 4 and a continuous feeding system. The pressurization system 5 , the feeding system 4 is communicated with the pressurization system 5 , and the output port of the mixing chamber 6 is communicated with the nozzle 17 .

[0020] The feeding system 4 includes an auxiliary water tank 41, a sand bucket 42, a mortar mixer 43, and a mortar pump 44 that provide water flow of the low-pressure pump 3. The output port of the low-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com