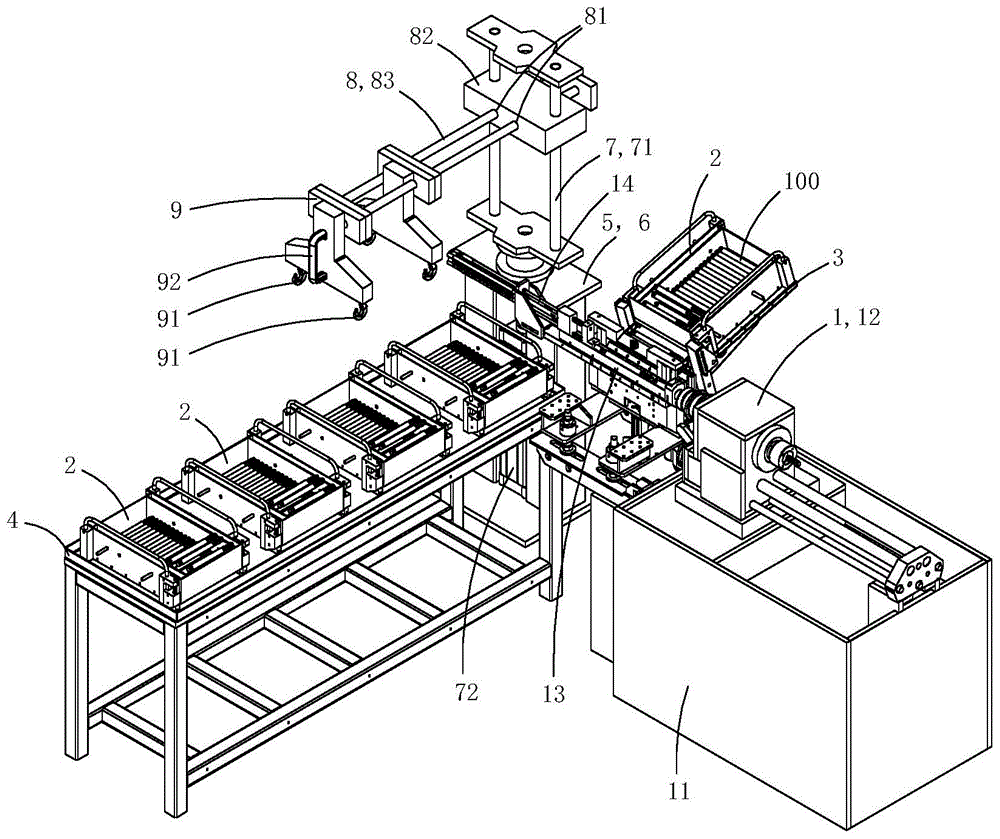

Combined type automatic feeding machine tool

An automatic feeding and combined technology, applied in milling machines, milling machine equipment, metal processing, etc., can solve the problems of non-detachable hoppers, cumbersome disassembly and maintenance, and difficulty in automatic loading and unloading of materials, so as to facilitate replacement and realize industrialized continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

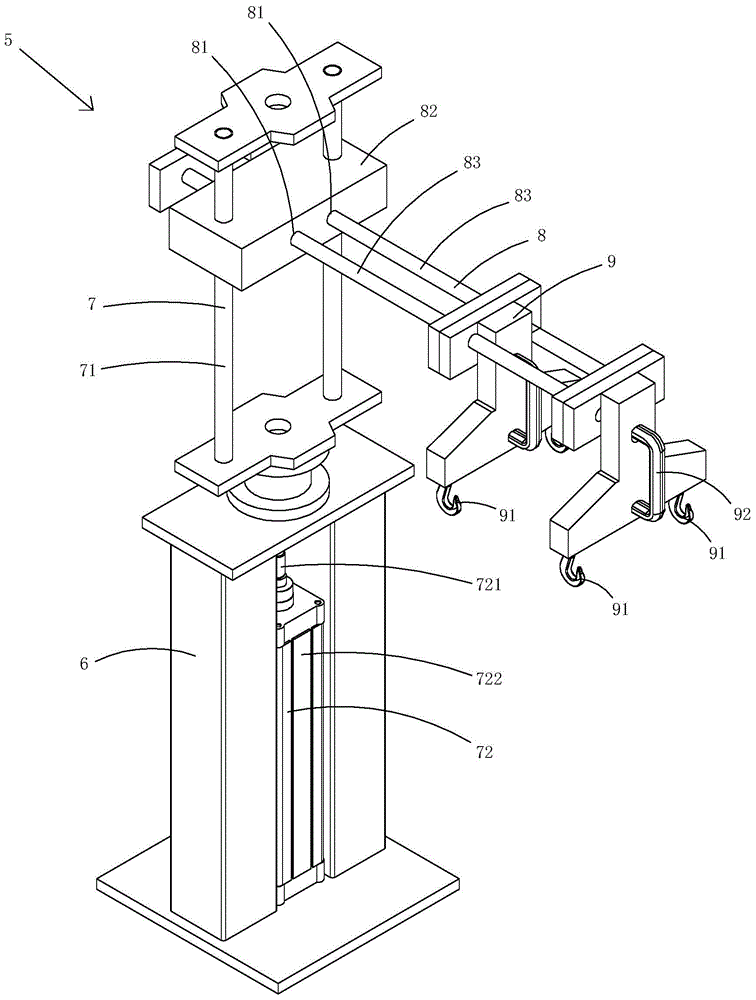

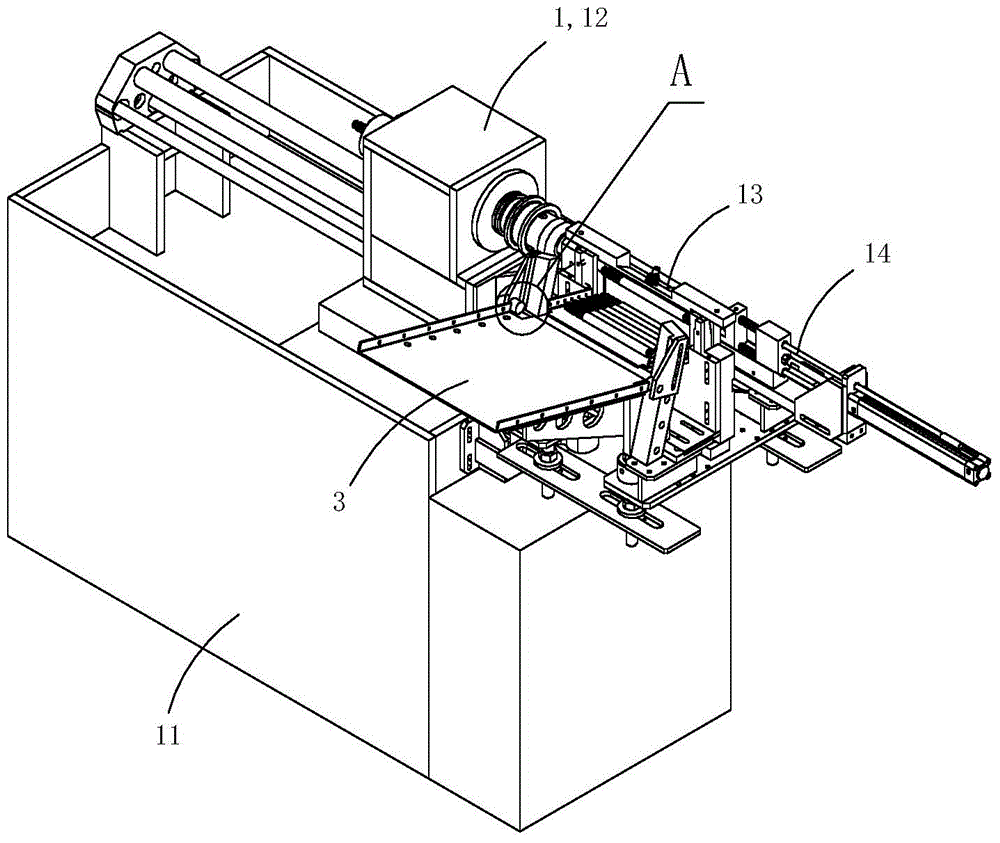

[0015] Figure 1 to Figure 8 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A schematic diagram of a three-dimensional structure of the feeding device in the machine tool shown; image 3 for figure 1 A schematic diagram of the three-dimensional structure of the machine tool shown after removing the feeding device, unloading rack and hopper; Figure 4 for image 3 Partial enlarged schematic diagram of A; Figure 5 for figure 1 A schematic diagram of a three-dimensional structure of the hopper in the machine tool shown; Figure 6 for Figure 5 A top view of the hopper shown; Figure 7 for Figure 5 A schematic cross-sectional structure of the hopper shown; Figure 8 for Figure 7 A schematic diagram of the structure of the shown hopper resting on the hopper support.

[0016] Present embodiment is a kind of combined automatic feeding machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com