Pipe cutting machine

A technology for cutting machines and pipes, applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc., can solve the problems of complex transmission system structure, increase production costs, and occupy a large space, so as to expand the scope of application, Space-saving and the effect of suppressing the transmission of motor vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

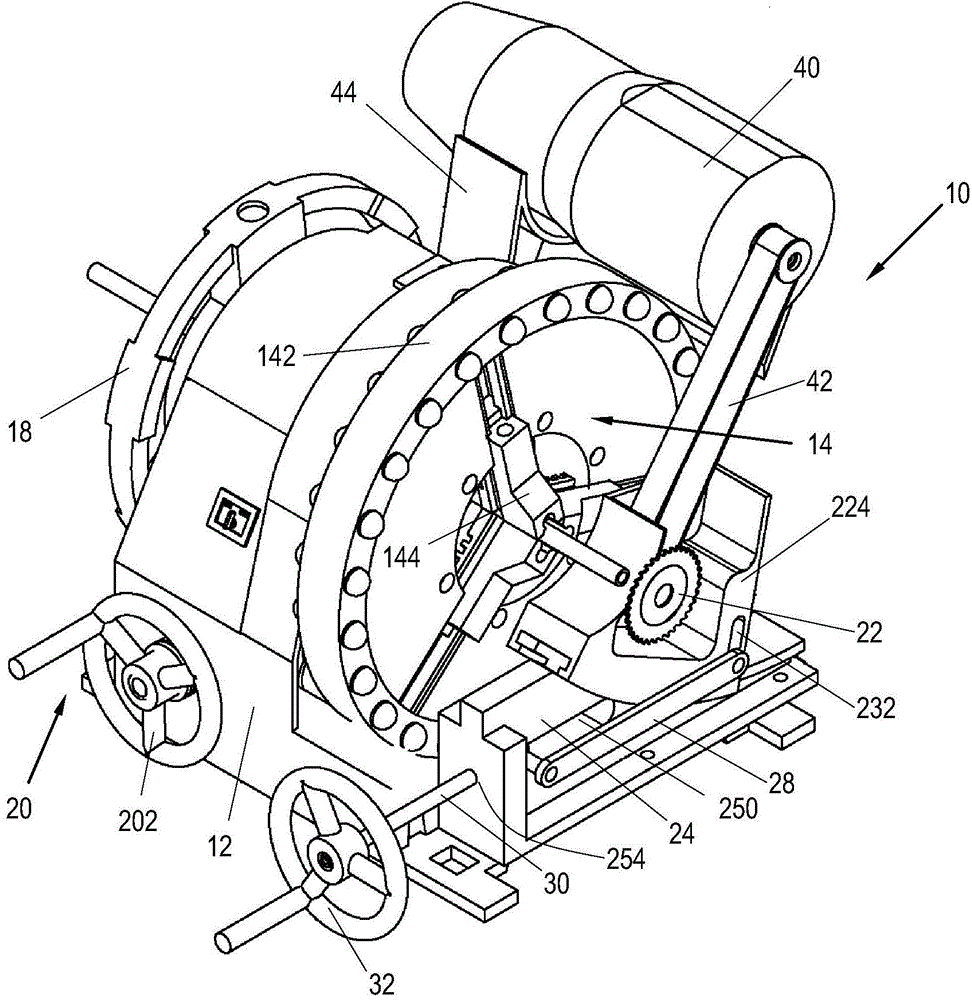

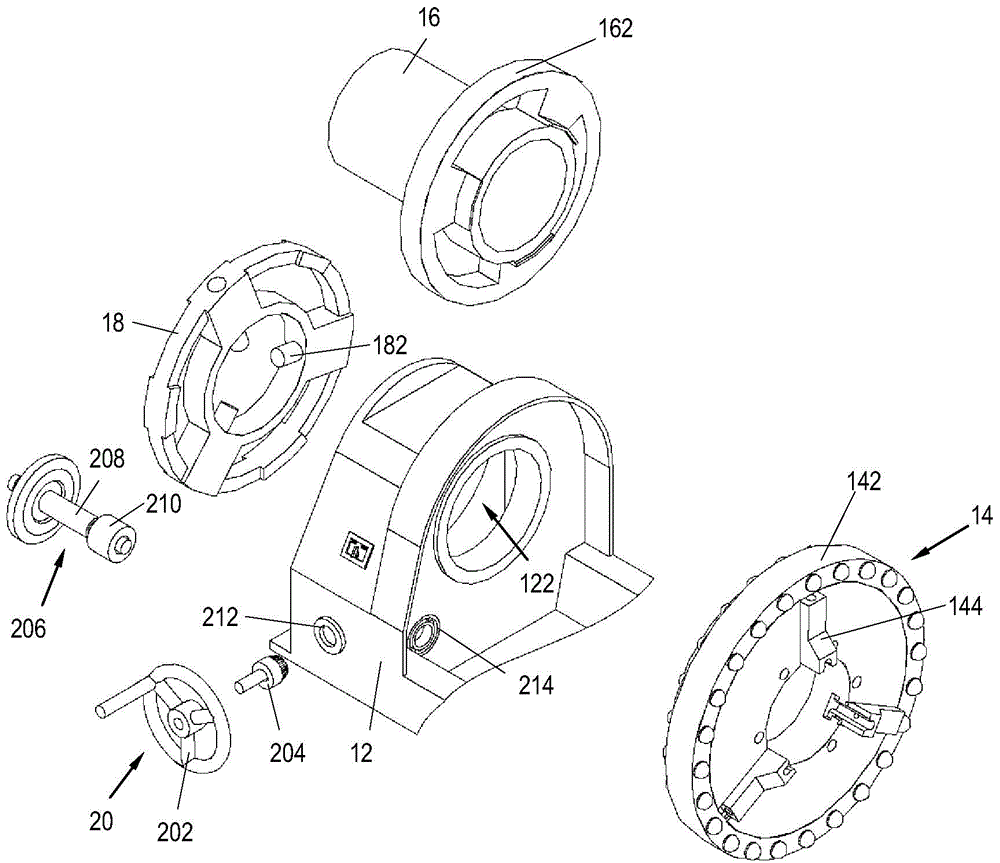

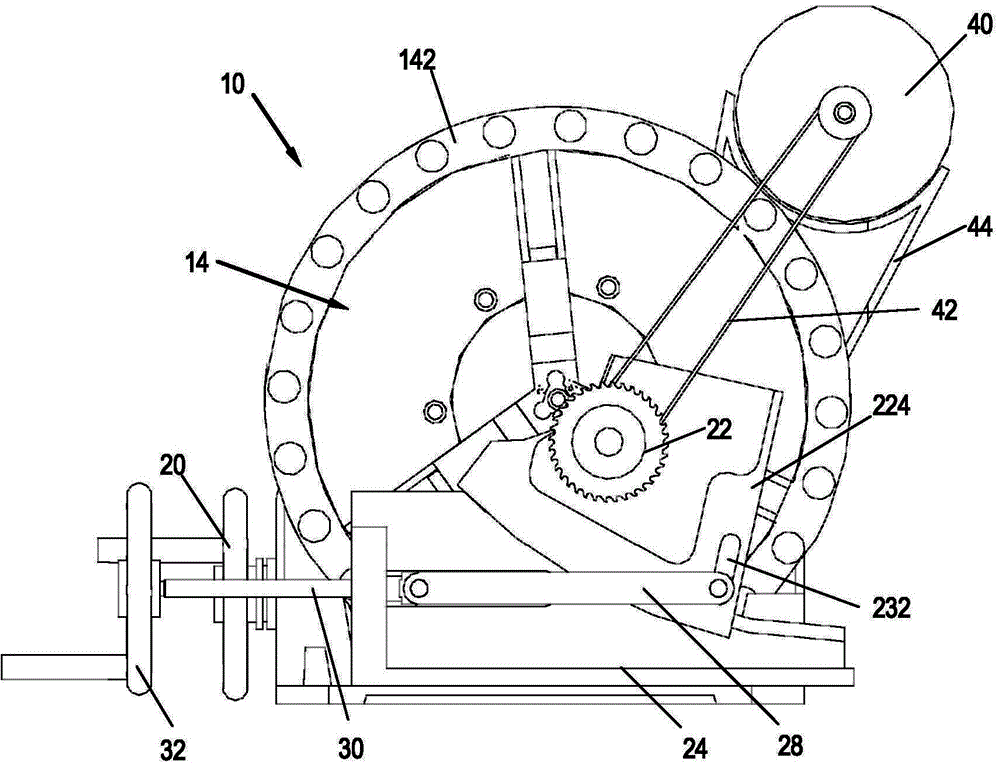

[0020] According to the first embodiment of the present invention, there is provided a figure 1 The pipe cutting machine 10 is shown. figure 2 An exploded perspective view of the pipe clamping device of the pipe cutting machine 10 according to the present invention is shown. When referring to the accompanying drawings to illustrate the pipe cutting machine 10 of the present invention, the longitudinal direction refers to the direction parallel to the axial direction of the pipe accommodating hole where the pipe to be cut is placed, that is, the direction parallel to the direction positioned at the cutting machine. The direction parallel to the axial direction of the pipe to be cut, and the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com