Kitchen garbage treatment device

A technology of kitchen garbage and processors, applied in the field of kitchen garbage processors, can solve the problems of wasting solid resources and increasing the difficulty of urban sewage treatment, achieving multiple social benefits and solving blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

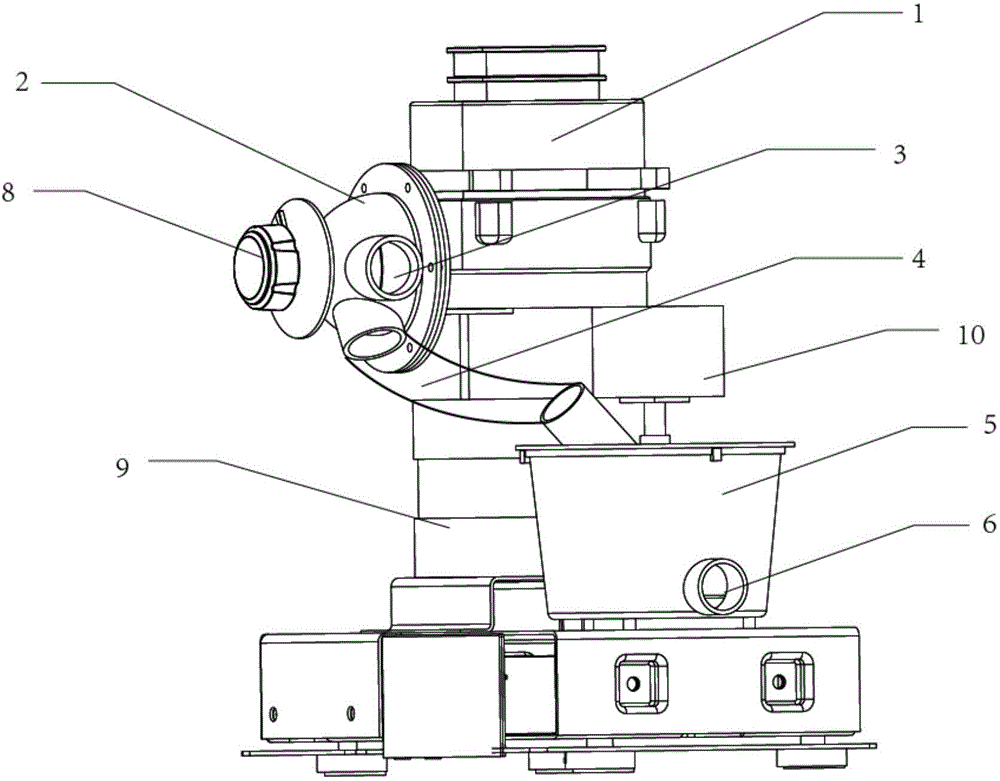

[0013] Such as figure 1 , figure 2 As shown, a kitchen garbage disposer includes a high-speed motor 9 and a grinder 1. The high-speed motor provides power for the grinder. The grinder 1 is respectively connected to two channels, one connected to the solid-liquid discharge port 3, and the other through the solid-liquid separation The device pipeline 4 is connected with the solid-liquid separator 5, and the closing and closing of the two passages are controlled by the distribution valve 2; a gear box 10 is installed on the solid-liquid separator 5, and the gear box 10 drives the solid-liquid separator 5 to squeeze and separate; One side of the liquid separator 5 is provided with a liquid discharge port 6; the other end of the solid-liquid separator 5 is connected to a solid waste container 7 through the solid discharge port.

[0014] The grinder 1 is driven by the high-speed motor 9 to grind, and the garbage will be ground and crushed in it initially, and the switch on the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com