Dual-frequency screen sealing device

A technology of sealing device and screen frame, which is applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of large overall weight of the sealing device and affect the use efficiency of the multi-frequency screen, etc., achieve low cost, good use effect, and improve cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

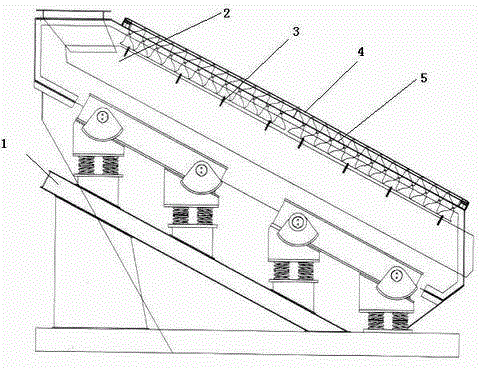

[0007] The embodiment is described in detail in conjunction with the accompanying drawings, a sealing device for a multiple frequency screen, which includes a screen body 1, a screen frame 2, and a steel pipe support 4 welded on the screen frame. The steel pipe support can be fixed in a vertical direction with the screen frame, or can be connected with The screen frame is fixed in the horizontal direction, and the upper part supported by the steel pipe is covered with canvas 5. The canvas is light in weight, and the waterproof and sealing effects are relatively ideal. Round hook 3, stay cord is tied on the round hook. The sealing device of the present invention is simple in processing, very convenient in installation and disassembly, and greatly improves the cost performance of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com