Flat nozzle

A technology of flat nozzles and backing plates, which is applied in the direction of spraying devices, spraying devices, etc., can solve the problems of shortening the life of the nozzles, being easily blocked by debris, and affecting the use of the nozzles, so as to increase the flow rate and not be easily blocked. The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

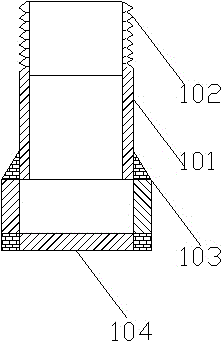

[0013] Such as figure 2 As shown, the flat nozzle includes a stainless steel tube 101, a stainless steel wire 103 and a stainless steel backing plate 104; the upper part of the stainless steel tube 101 is provided with an external thread 102; the stainless steel wire 103 is fixedly arranged outside the stainless steel tube 101 bottom; The stainless steel backing plate 104 is fixedly arranged under the stainless steel wire 103 .

[0014] In this embodiment, the stainless steel wire 103 is fixedly arranged outside the lower part of the stainless steel pipe 101 by welding.

[0015] In this embodiment, the stainless steel backing plate 104 is fixedly arranged under the stainless steel wire 103 by welding.

[0016] The middle of the stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com