Belt type sludge dewatering machine

A sludge dewatering machine and rack technology, which is used in dewatering/drying/concentrating sludge treatment, moving filter element filters, filtration and separation, etc. Sludge filtration efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

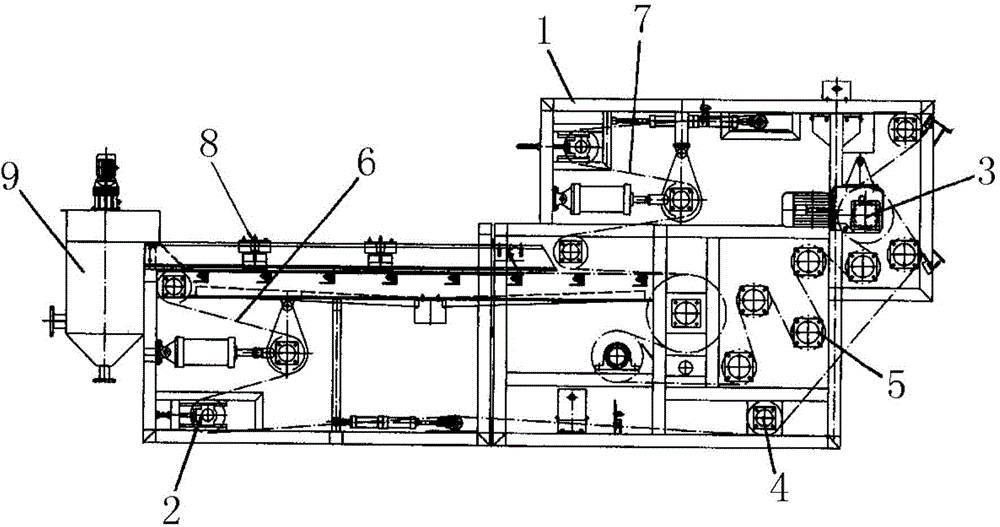

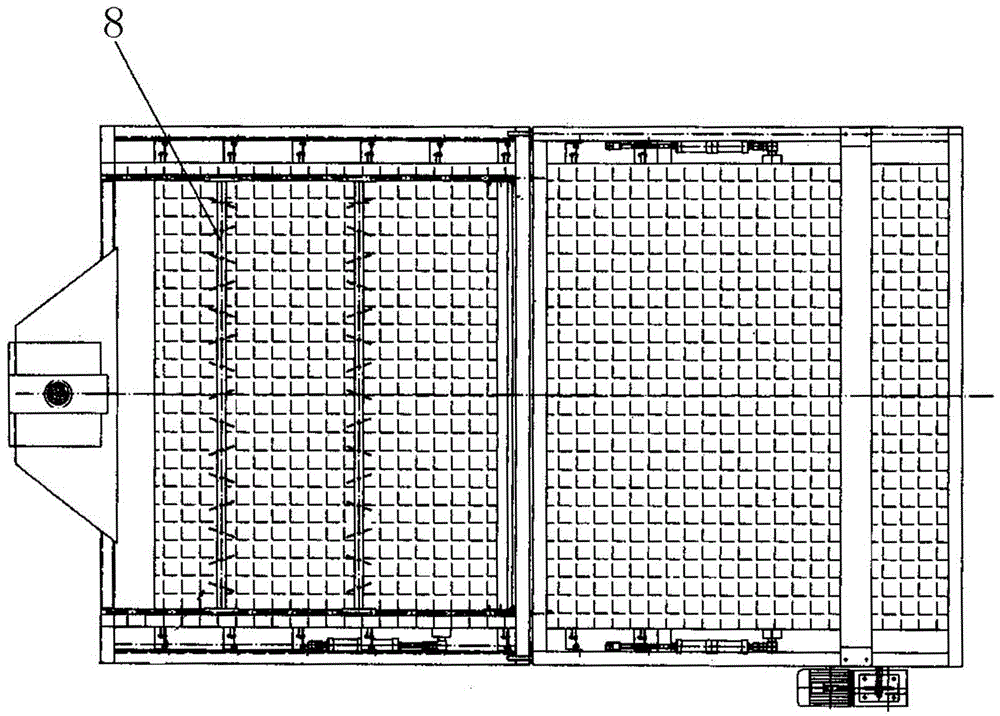

[0010] Such as figure 1 , 2 As shown, the present invention is provided with driving roller 2 at the lower part of one end of frame 1, driven roller 3 is arranged at the upper part of one end of frame 1, is provided with a plurality of guide rollers 4 and a plurality of S-shaped distributions on frame 1 Squeeze roll 5, fabric mesh belt 6 wraps around drive roll 2, multiple squeeze rolls 5 and multiple guide rolls 4 and spreads them flat on the bracket above frame 1, and squeezes mesh belt 7 around passive roll 3 and multiple guide rolls On the squeeze roller 5 that is S shape distribution, on the frame 1 above the cloth net belt 6, be provided with two mutually parallel cloth distributors 8.

[0011] Through the above settings, the sewage is pumped into the sludge mixing tank and mixed with the polymer flocculant, so that the fine suspended matter in the sludge will form larger rubber feather particles through the action of the polymer flocculant, and then flow in the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com