Microscopic intraocular instrument

An instrument and head technology, applied in the field of microscopic intraocular scissors, can solve the problems of difficult operation, limited use range, inability to cut deep into the deep, and achieve the effect of reducing costs and improving sustainable utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

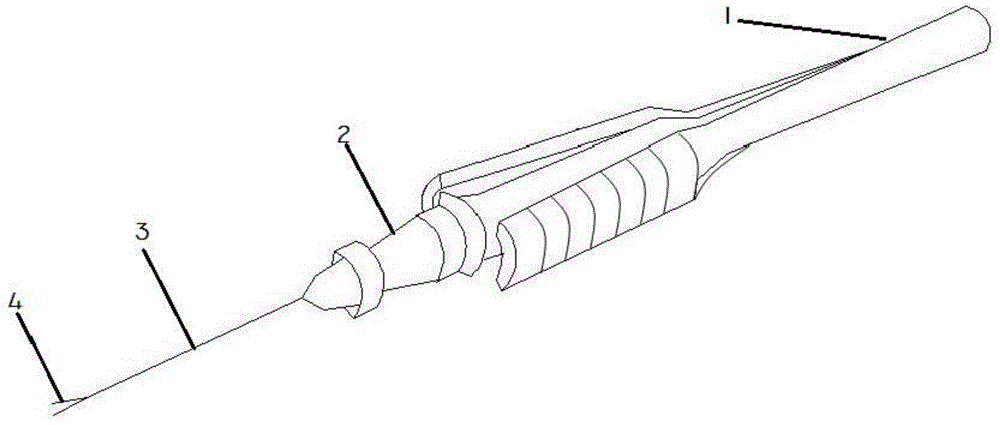

[0030] figure 1 It is a schematic diagram of the overall structure of the first embodiment of the microscopic intraocular device A according to the present invention.

[0031] Such as figure 1 As shown, in the first embodiment of the present invention, the microscopic intraocular instrument A includes a handle 1, a connecting part 2 and a head 3, and the handle 1 and the head 3 are fixedly arranged on the connecting part respectively. The two ends of the part 2, the handle 1 is detachably connected to the connecting part 2, the head 3 is detachably connected to the connecting part 2, the head 3 includes a pincer 4, and the The clamping scissors 4 include two parts of the scissors, and the two parts of the scissors are capable of relative displacement and jointly form a holding force.

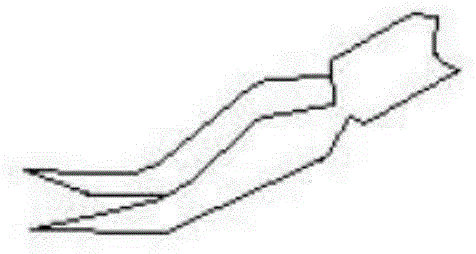

[0032] figure 2 for figure 1 Schematic diagram of the pinch zoom structure in .

[0033] Such as figure 2 As shown, in the first embodiment of the present invention, the clip scissors 4 ...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 lies in the change of the structural shape of the clipper 4 .

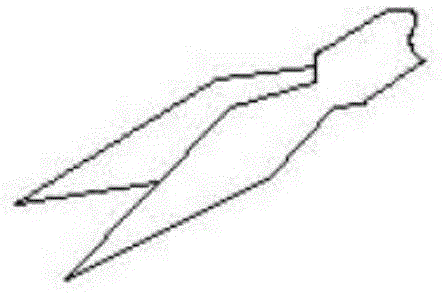

[0036] image 3 It is a schematic diagram of the clipping enlarged structure in the second embodiment of the microscopic intraocular instrument A according to the present invention.

[0037] Such as image 3 As mentioned above, in the second embodiment of the present invention, the clip scissors 4 in the microscopic intraocular instrument A are horizontal straight scissors 42, and the two parts of the scissors in the horizontal straight scissors 42 are in a straight line structure and are connected to each other. Symmetrical setting.

Embodiment 3

[0039] The difference between this embodiment and Embodiment 1 lies in the change of the structural shape of the clipper 4 .

[0040] Figure 4 It is a schematic diagram of the clipping enlarged structure in the third embodiment of the microscopic intraocular instrument A according to the present invention.

[0041] Such as Figure 4 As mentioned above, in the third embodiment of the present invention, the clipping scissors 4 in the microscopic intraocular instrument A are horizontal angle scissors 43, and the two parts of the horizontal angle scissors 43 are arranged in a misaligned position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com