Absorbable hollow pin for lock pin and preparation method

A technology of hollow nails and locking nails, which is applied in the field of medical equipment, can solve the problems of unusable, low mechanical strength and decreased mechanical properties of absorbable nails, and achieve the effects of small deformation, relief of economic burden and pain, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

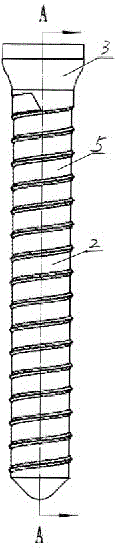

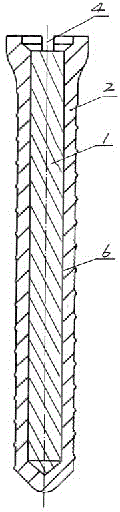

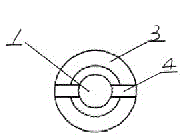

[0027] An absorbable hollow nail for locking nails, which includes a locking nail 1 and an absorbable hollow nail 2; the absorbable hollow nail 2 is a screw-like hollow nail of polylactic acid resin, and the screw-like absorbable hollow nail of polylactic acid resin The hollow nail 2 includes a screw head 3 and a screw rod 5, the screw head 3 is provided with a screw groove 4, the outside of the screw rod 5 is provided with threads, the inside of the screw rod 5 is a hollow cylinder 6, and the hollow cylinder 6 has a built-in locking screw 1 matching the volume of the hollow cylinder 6 .

[0028] The screw groove 4 is in-line.

[0029] The length of the absorbable hollow nail 2 is 60mm, the diameter of the screw rod 5 is 8.0mm, the length of the hollow cylinder 6 inside the screw rod is 80% of the total length of the screw, i.e. 48mm, and the diameter of the hollow cylinder 6 is 50% of the diameter of the screw rod 5, That is 4.0mm;

[0030] The locking nail 1 is a titanium ...

Embodiment 2

[0035] Embodiment 2: a kind of absorbable hollow nail that is used for locking nail, it comprises locking nail 1 and absorbable hollow nail 2; Absorbable hollow nail 2 is the screw-shaped hollow nail of polylactic acid resin, the screw of polylactic acid resin Shaped absorbable hollow nails include a screw head 3 and a screw rod 5, the screw head 3 is provided with a screw groove 4, the outside of the screw rod 5 is provided with threads, the inside of the screw rod 5 is a hollow cylinder 6, and the hollow cylinder 6 has a built-in lock matching the volume of the hollow cylinder. Nail 1.

[0036] The screw groove 4 is in-line.

[0037] The length of the absorbable hollow nail 2 is 30mm, the diameter of the screw rod 5 is 8.0mm, and the length of the hollow cylinder inside the screw rod is 80% of the total length of the absorbable hollow nail 2, i.e. 24mm; the diameter of the hollow cylinder 6 is the diameter of the screw rod 5. 40%, or 3.2mm.

[0038] The locking nail 1 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Screw diameter | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com