Engineering platform hoist

A hoist and platform technology, applied in applications, home appliances, cleaning equipment, etc., can solve the problems of prone to overturning, increase the danger of high-altitude work, time difference, etc., to prevent overturning and ensure stable working power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

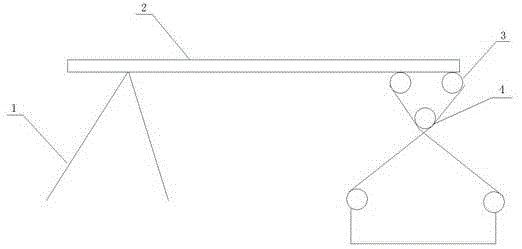

[0013] Example 1 as figure 1 As shown, a platform hoist for engineering in this embodiment includes a support rod 2 and a support base 1, and the support base 1 is fixed on the floor or other fixed surface at the top of the floor. Support bar 2 is hinged with support base 1, and now, support bar 2 can rotate around support base 1, can rotate to suitable position lifting platform when needing to use support bar 2, can turn back original position when not applicable. The support bar 2 is provided with a pulley block and a rope, and the rope pulls the pulley block through a power mechanism. The pulley block includes a movable pulley 4 and two fixed pulleys 3, the fixed pulley 3 is fixed on the support rod 2, the movable pulley 4 is fixed on the support rod 2, and the two fixed pulleys 3 and one movable pulley 4 form a triangular stable structure. It can ensure that the platform is always on the same level, and when the platform is displaced at a certain height, it can buffer the...

Embodiment 2

[0014] Embodiment 2 The difference between this embodiment and Embodiment 1 is that the movable pulley 4 is movable, that is, the movable pulley 4 is connected with the fixed pulley 3 through a rope to form a triangular structure. Now, the fixed pulley 4 can be adjusted in height, and according to the principle of the pulley block, the required power can be saved when the platform is lifted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com