Automatic towel drying device

A technology for drying devices and towels, which can be applied to home appliances, etc., can solve the problems of inconvenient installation, inaccurate control, and high cost, and achieve the effects of precise control, good energy saving effect, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

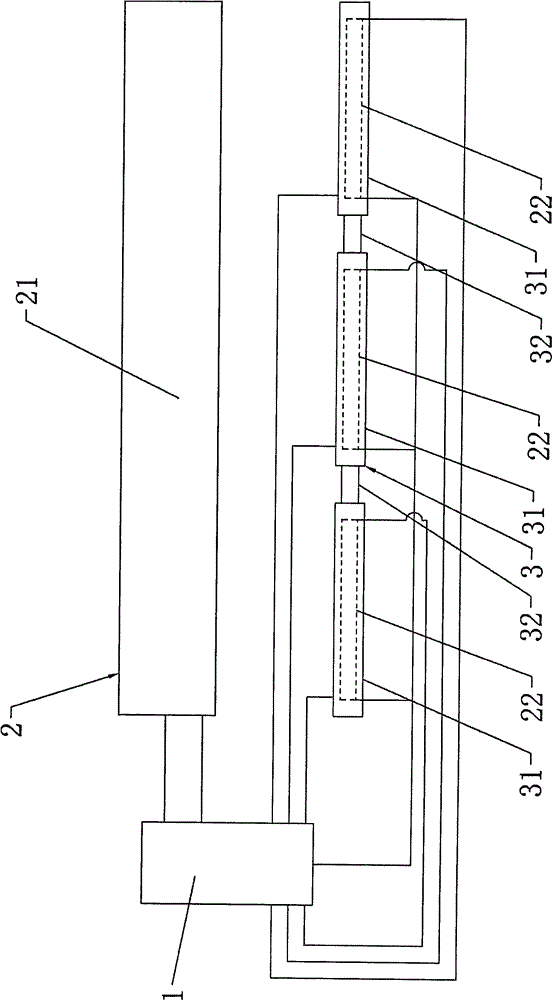

[0022] Embodiment 1, an automatic towel drying device, including a controller 1, a drying assembly 2, and a towel rack 3 for hanging towels. The towel rack 3 includes at least two conductive parts 31 arranged at intervals in sequence. An insulating part 32 is provided between two adjacent conductive parts 31 , and the drying assembly 2 and each conductive part 31 are respectively electrically connected to the controller 1 . Among them, the conductive part 31 is made of aluminum alloy material, that is, the conductive part 31 is an aluminum alloy conductive part, and the length of the conductive part 31 is 220mm; the insulating part 32 is made of plastic material, and the insulation cannot be used to connect two adjacent The plastic joint of the conductive part 31; at this time, the towel hanging part of the towel rack 3 is arranged in a group of aluminum alloy conductive part-plastic joint-aluminum alloy conductive part-plastic joint-aluminum alloy conductive part, totally 4 gr...

Embodiment 2

[0026] Embodiment 2, an automatic towel drying device, including a controller 1, a drying assembly 2, and a towel rack 3 for hanging towels. The towel rack 3 includes at least two conductive parts 31 arranged at intervals in sequence. An insulating part 32 is provided between two adjacent conductive parts 31 , and the drying assembly 2 and each conductive part 31 are respectively electrically connected to the controller 1 . Among them, the conductive part 31 is made of stainless steel material, that is, the conductive part 31 is a stainless steel conductive part, and the length of the conductive part 31 is 100mm; the insulating part 32 is made of plastic material, and the insulation cannot be used to connect two adjacent conductive parts. 31 plastic connector; at this time, the towel hanging part of the towel rack 3 is arranged into a group of stainless steel conductive part-plastic connector-stainless steel conductive part-plastic connector-stainless steel conductive part, tot...

Embodiment 3

[0030] Embodiment 3, an automatic towel drying device, including a controller 1, a drying assembly 2, and a towel rack 3 for hanging towels. The towel rack 3 includes at least two conductive parts 31 arranged at intervals in sequence. An insulating part 32 is provided between two adjacent conductive parts 31 , and the drying assembly 2 and each conductive part 31 are respectively electrically connected to the controller 1 . Among them, the conductive part 31 is made of aluminum alloy material, that is, the conductive part 31 is an aluminum alloy conductive part, and the length of the conductive part 31 is 220mm; the insulating part 32 is made of plastic material, and the insulation cannot be used to connect two adjacent The plastic joint of the conductive part 31; at this time, the towel hanging part of the towel rack 3 is arranged in a group of aluminum alloy conductive part-plastic joint-aluminum alloy conductive part-plastic joint-aluminum alloy conductive part, totally 4 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com